Dual mode luminous rare earth doped cerium fluoride nano crystal, preparation method and surface modification method thereof

A rare earth doping, cerium fluoride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of single surface polarity modification of fluorescent material nanocrystal morphology, single luminescence wavelength, and difficulty in meeting application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to another embodiment of the present invention, a method for preparing rare earth-doped cerium fluoride nanocrystals with dual-mode light emission is provided, wherein the chemical composition formula of the rare earth-doped cerium fluoride nanocrystals is Ce 0.74 f 3 : 0.2Yb / xTm / (0.06-x) Tb, x=0.01-0.05, described method comprises the following steps:

[0033]a) According to the chemical composition formula, respectively weigh ytterbium oxide, thulium oxide and terbium oxide in a stoichiometric ratio, and dissolve them with concentrated nitric acid, and weigh cerium nitrate in a stoichiometric ratio, and heat and dissolve them in water to obtain the rare earth ions solution, the rare earth ion is an ion in its stable form.

[0034] b) According to the chemical composition formula, weigh the fluoride salt with a stoichiometric excess of less than 5%, and dissolve it in water to obtain a fluoride ion solution. In this step, preferably less than 5% excess fluo...

Embodiment 1

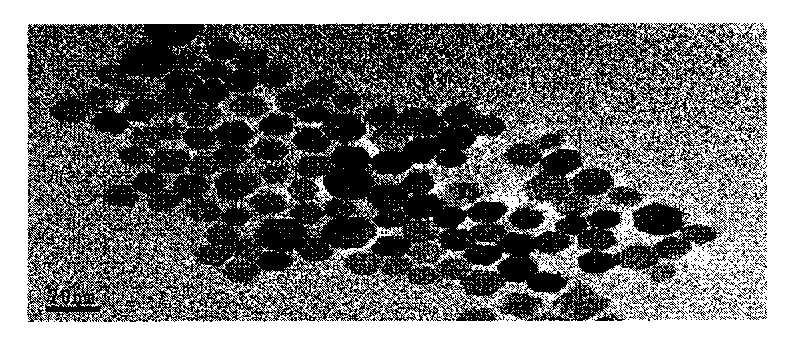

[0051] Embodiment 1: prepare Ce 0.74 f 3 :0.2Yb / 0.05Tm / 0.01Tb nanoparticles

[0052] Measure 1850 μl of the above-prepared Ce(NO 3 ) 3 solution (0.2M), 500 μl of Yb(NO 3 ) 3 solution (0.2M), 125 μl of the Tm(NO 3 ) 3 solution (0.2M) and 25 μl of Tb(NO 3 ) 3 Mix the solution (0.2M) evenly, add 10ml of aqueous solution containing 0.75g KOH, 15ml of absolute ethanol, and 10ml of oleic acid and stir vigorously until transparent, and add a slight excess of 2ml of KF solution, a white emulsion appears quickly and stir thoroughly for 15 Minutes, immediately put the mixed homogeneous emulsion into a 50ml hydrothermal reaction kettle, react at a temperature of 180°C for 8 hours, then cool the completed sample to room temperature, centrifuge, and wash with absolute ethanol / cyclohexane, The residue was removed and dispersed with cyclohexane.

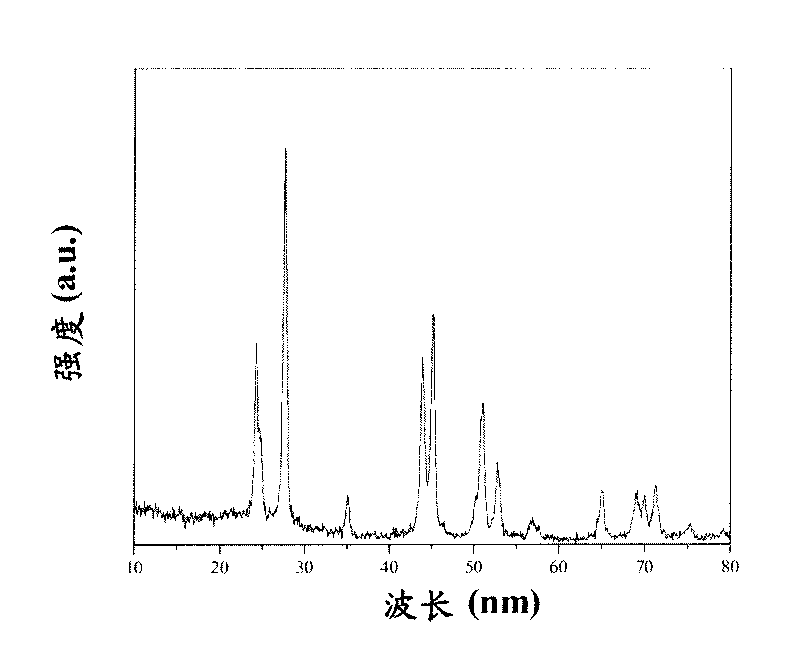

[0053] Ce prepared in this example 0.74 f 3 : The XRD diffraction patterns of 0.2Yb / 0.05Tm / 0.01Tb nanocrystals are as follows figure ...

Embodiment 2

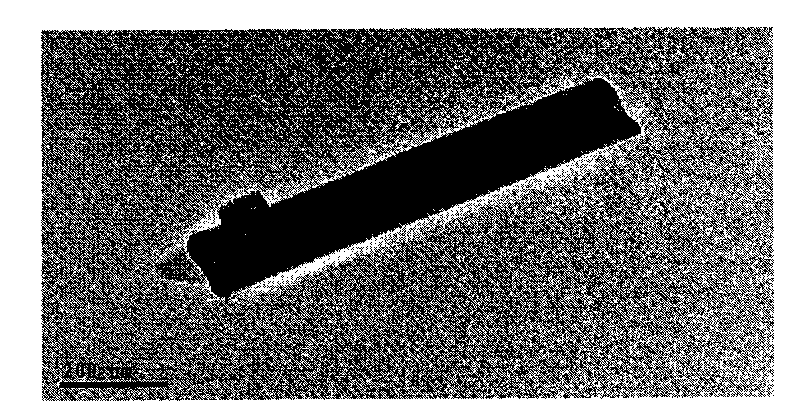

[0054] Embodiment 2: preparation Ce 0.73 f 3 :0.2Yb / 0.03Tm / 0.03Tb nanorods

[0055] Measure 1850 μl of the above-prepared Ce(NO 3 ) 3 solution (0.2M), 500 μl Yb(NO 3 ) 3 solution (0.2M), 75 μl of Tm(NO 3 ) 3 solution (0.2M), 75 μl of Tb(NO 3 ) 3 Mix the solution (0.2M) evenly, add 10ml of aqueous solution containing 0.75g KOH, 15ml of absolute ethanol, and 10ml of oleic acid and stir vigorously until transparent, then add a slight excess of 2ml of KF solution, a white emulsion appears quickly and stir thoroughly for 15 minutes, Immediately put the mixed homogeneous emulsion into a 50ml hydrothermal reactor and react at 180°C for 24 hours. However, the sample after the reaction is cooled to room temperature, centrifuged, and washed with absolute ethanol / cyclohexane to remove the residue, and use cyclohexane dispersion.

[0056] Ce of the sample prepared in this embodiment 2 0.73 f 3 : The X-ray diffraction pattern of 0.2Yb / 0.03Tm / 0.03Tb is similar to figure 1 , sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com