Cationic reactive Gemini polyurethane surfactant and preparation method thereof

A surfactant and reactive technology, which is applied in the field of cationic reactive gemini polyurethane surfactant and its preparation, can solve the problems of easy migration and precipitation, and achieve the effects of solving environmental pollution problems, excellent surface activity, and solving migration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

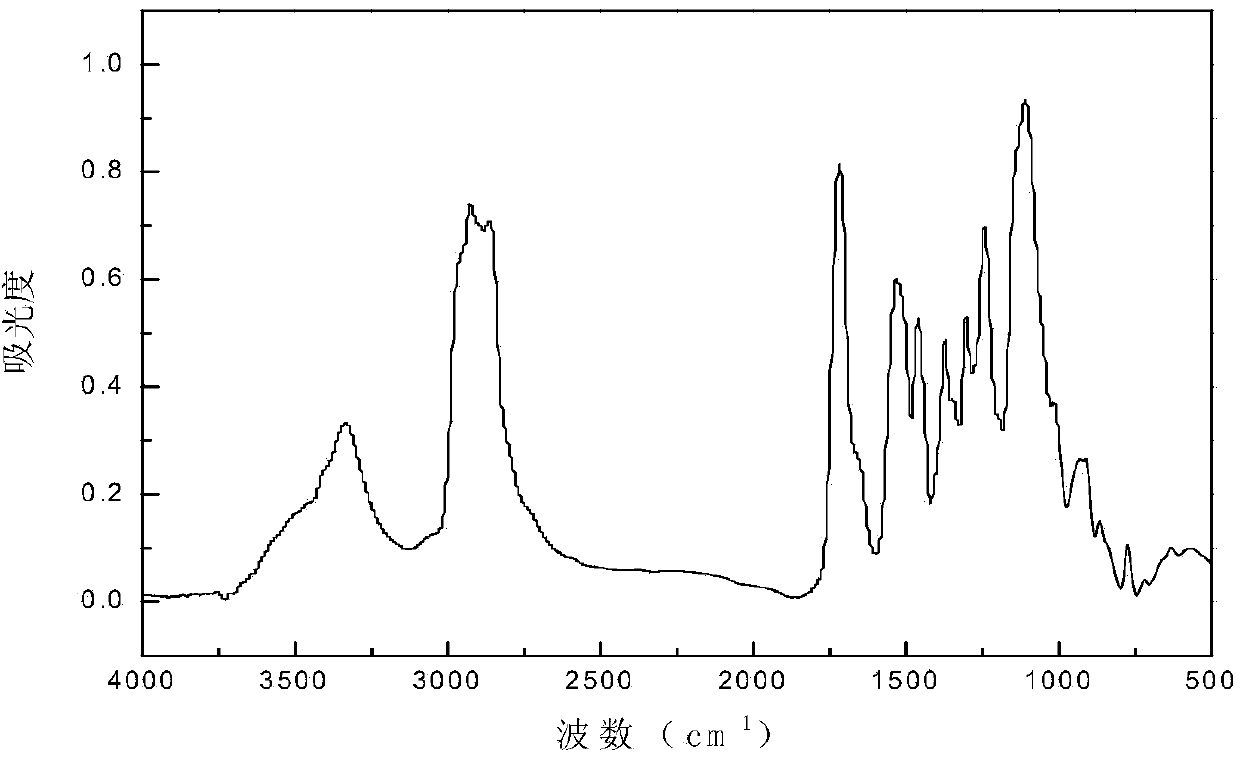

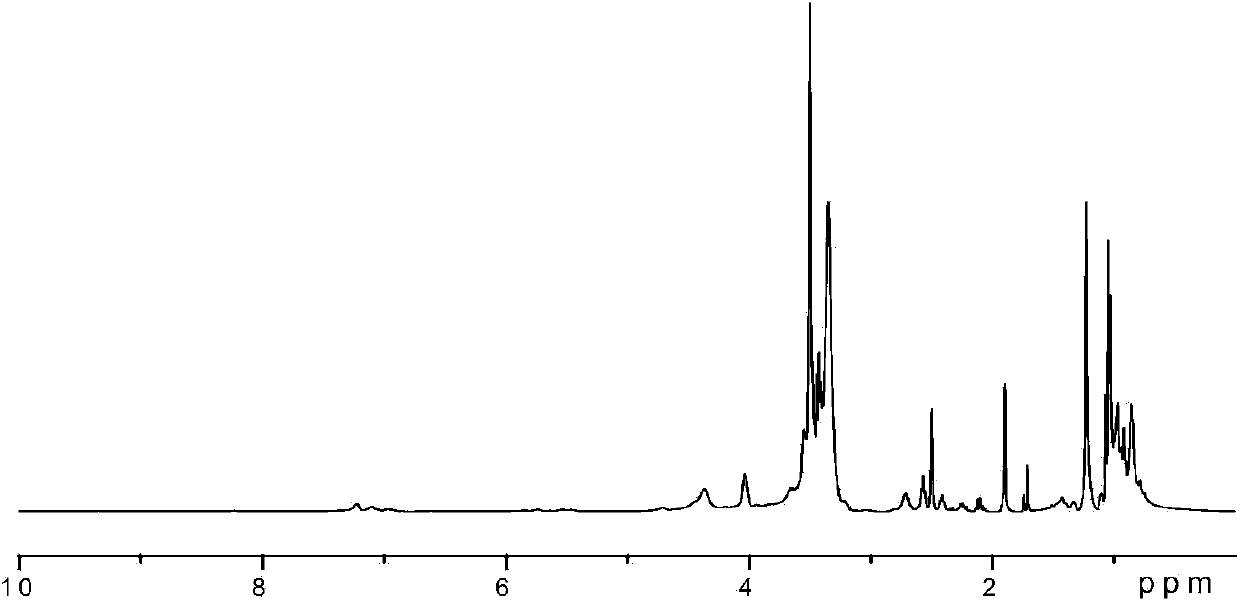

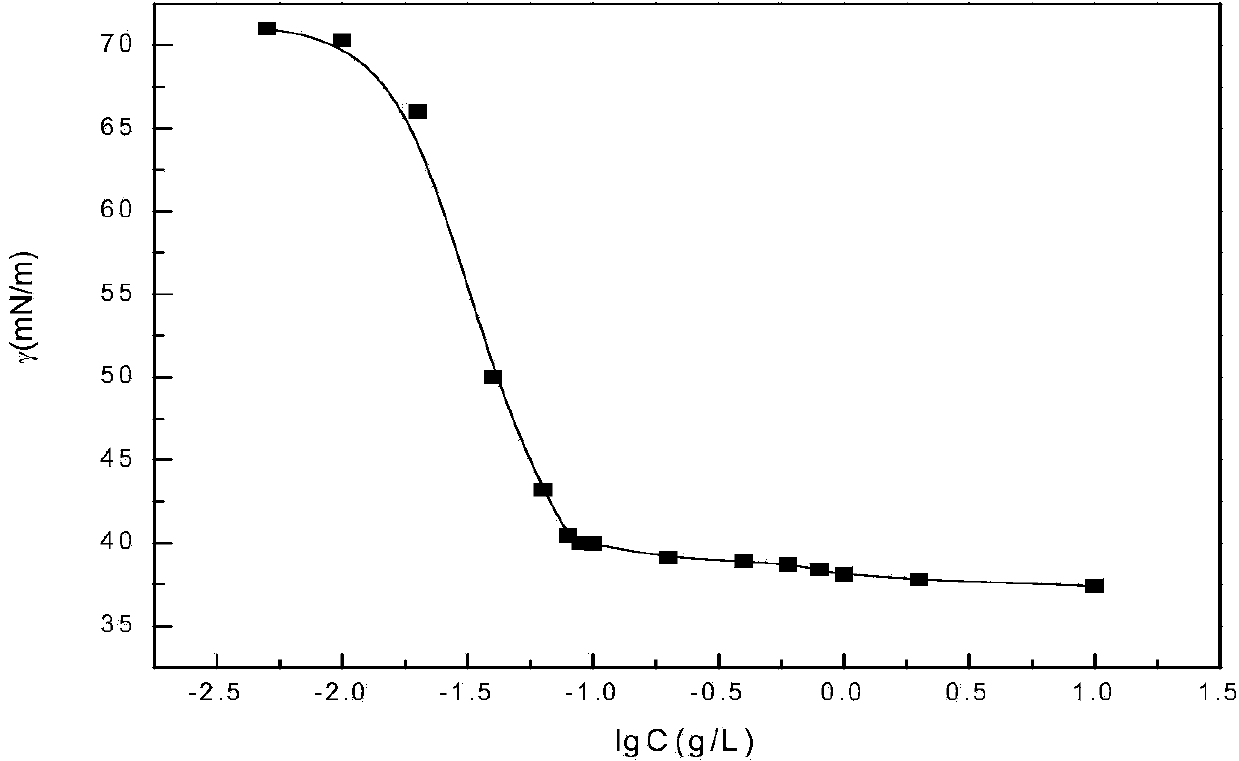

Method used

Image

Examples

Embodiment 1

[0037] (1) Add 140.5 parts of pre-dehydrated dodecylamine polyoxyethylene (10) ether (the number of carbon atoms in the hydrophobic carbon chain part is 12, and the number of hydrophilic ethoxy groups m+n=10) into the heated, Add 100 parts of isophorone diisocyanate and 0.12 parts of catalyst bismuth laurate into the sealed reaction kettle of the temperature control and dispersion device, and react at 60°C for 3 hours to reach the theoretical residual isocyanate value.

[0038] (2) Add 45 parts of PPG400 (polypropylene glycol with a relative molecular mass of 400) and continue to react at 60°C for 3 hours to reach the theoretical residual isocyanate value.

[0039](3) Add 23.6 parts of blocking agent butanone oxime to block the remaining isocyanate in the prepolymer, react at 80 degrees for 2 hours, no remaining isocyanate is detected, cool down to 40°C, add neutralizing agent glacial acetic acid 13.5 parts fully neutralize the cationic groups in the prepolymer, and then add 1...

Embodiment 2

[0046] (1) Add 41.4 parts of pre-dehydrated octylamine polyoxyethylene (2) ether (the number of carbon atoms in the hydrophobic carbon chain part is 8, and the number of hydrophilic ethoxy groups m+n=2) into the heated, controlled Add 100 parts of hydrogenated dibenzylidene diisocyanate and 0.2 parts of zinc isooctanoate as a catalyst to react at 70°C for 2 hours to reach the theoretical residual isocyanate value in the sealed dispersion kettle of the mild dispersion device.

[0047] (2) Add 8.6 parts of 1,4-butanediol and continue to react at 70°C for 2 hours to reach the theoretical residual isocyanate value.

[0048] (3) Add 15.3 parts of blocking agent acetone oxime to block the remaining isocyanate in the prepolymer, react at 80 degrees for 4 hours, no remaining isocyanate is detected, cool down to 40°C, add 11.5 parts of neutralizing agent glacial acetic acid neutralize the cationic groups in the prepolymer, and then add 413 parts of deionized water to disperse with high...

Embodiment 3

[0051] (1) 604 parts of octadecylamine polyoxyethylene (40) ether (the number of carbon atoms in the hydrophobic carbon chain part is 18, and the number of hydrophilic ethoxy groups m+n=40) that has been dehydrated in advance is added to the heated, Add 100 parts of hexamethylene diisocyanate and 0.5 parts of catalyst bismuth naphthenate to the sealed dispersion kettle of the temperature control and dispersion device, and react at 60°C for 4 hours to reach the theoretical residual isocyanate value.

[0052] (2) Add 149 parts of PEG1000 (polyethylene glycol with a relative molecular mass of 1000) and continue to react at 60°C for 4 hours to reach the theoretical residual isocyanate value.

[0053] (3) Add 55 parts of blocking agent acetanilide to block the remaining isocyanate in the prepolymer, react at 75°C for 4 hours, no remaining isocyanate is detected, cool down to 40°C, add neutralizing agent glycolic acid 22.7 1 part fully neutralizes the cationic groups in the prepolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com