Self-shielded flux-cored wire for X80 pipeline steel

A flux-cored wire and self-protection technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as the disadvantage of mechanical properties of deposited metal, achieve good welding process performance, improve slag removal performance, Fill evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further specifically explained through the following examples: a high-toughness self-shielding flux-cored welding wire for all-position welding of X80 pipeline steel, using a commercially available ordinary H08A steel strip as the wire sheath, and adopting an alloy transition method, It is made by the common flux-cored wire production process.

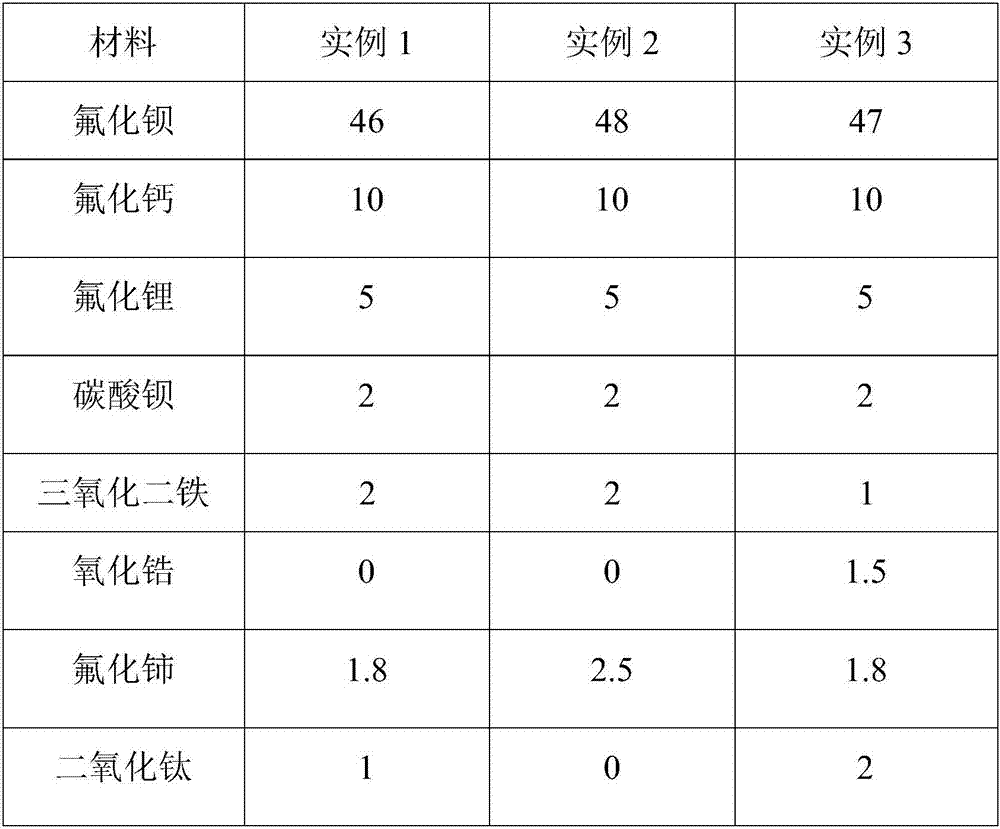

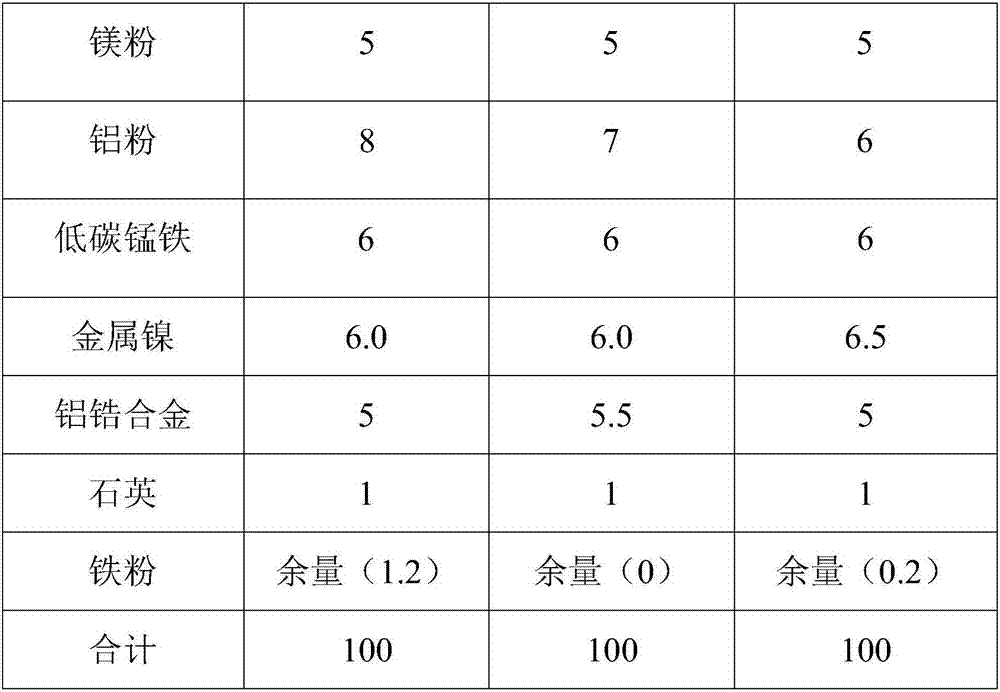

[0038] Table 1 is the chemical composition of the flux core powder of the self-shielding flux cored welding wire in each embodiment

[0039]

[0040]

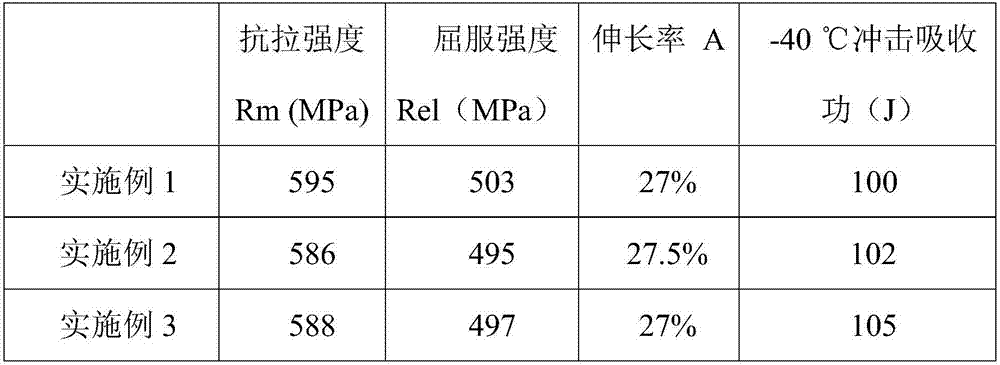

[0041] The welding test plates of the mechanical properties of the self-shielding flux-cored wire deposited metal in Examples 1, 2 and 3 are all prepared as follows: the test plates are prepared with reference to AWS A5.29 / A5.29M, and the test plates are selected from Q235 steel plate 250mm × 250mm × 20mm , The backing plate is selected as 9mm Q235 steel plate. The groove of the test plate is V-shaped, and the groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com