High-temperature burning sticking preventing coating

An anti-sticking and coating technology, applied in the field of high-temperature anti-sticking coatings, can solve the problems of preventing steel slag sticking, achieve good adhesion, excellent anti-sticking function and protection function, and solve the effect of preventing steel slag sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

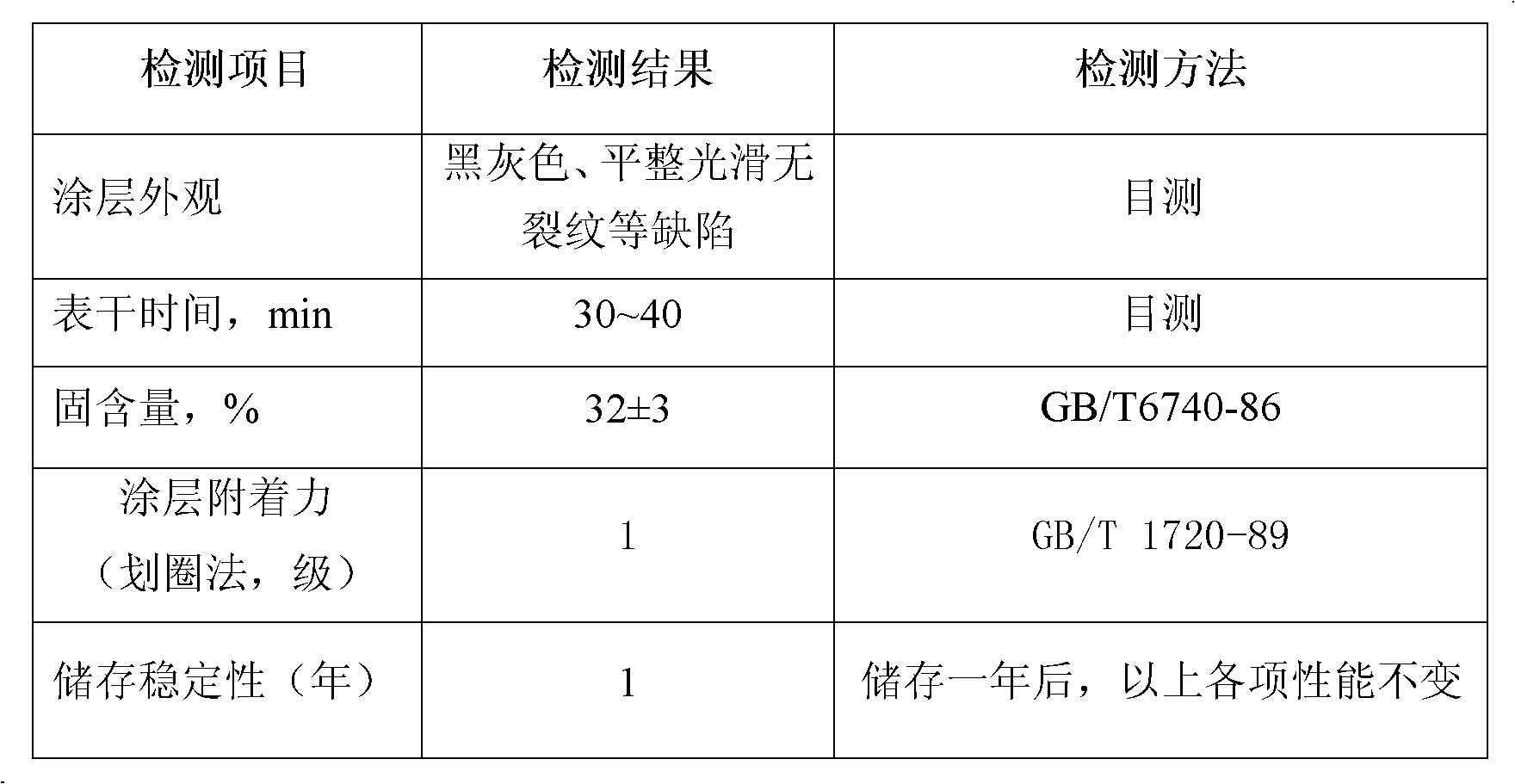

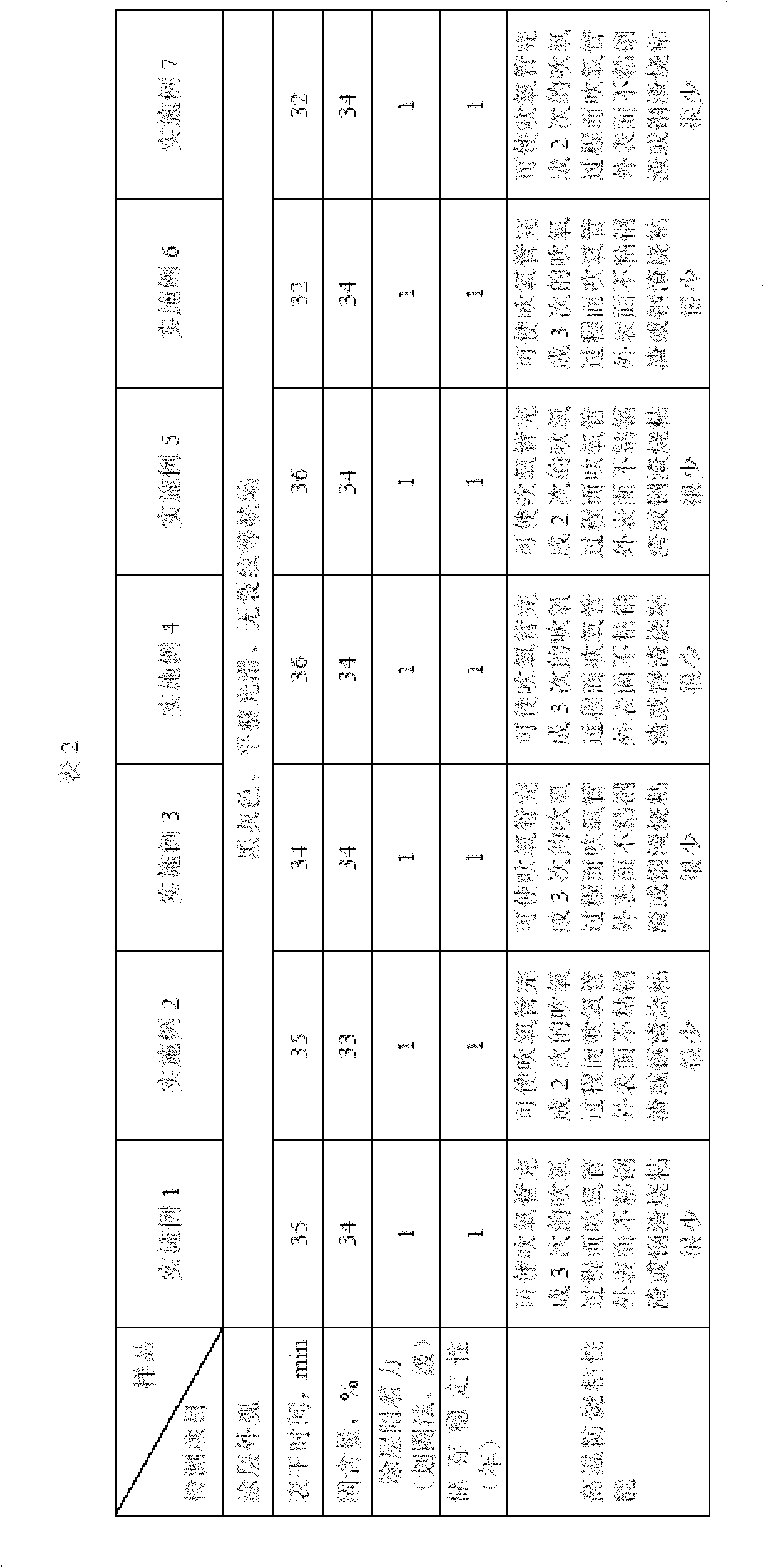

Examples

Embodiment 1

[0022] Weigh 800.0 grams of graphite, 170.0 grams of molybdenum disulfide, 100.0 grams of cerium fluoride, 310.0 grams of metal oxides (120.0 grams of antimony trioxide, 190.0 grams of copper oxide) and 90.0 grams of fumed silicon dioxide and 6.0 grams of potassium pyrophosphate Put it into a ball mill jar, then add 300.0 grams of distilled water for grinding; after the dispersion is even, add 500 grams of silicon acrylic emulsion and the rest of distilled water to disperse evenly to obtain 5 kg of high-temperature anti-sticking coating.

Embodiment 3

[0025] Embodiment 3 (5kg):

[0026] graphite

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com