Preparation method of bearing lubrication oil

A technology of lubricating oil and mixture for bearings, which is applied in the field of preparation of lubricating oils for bearings, can solve the problems of high price, radial size, large vibration and noise, etc., achieve excellent bearing capacity, improve wear resistance, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

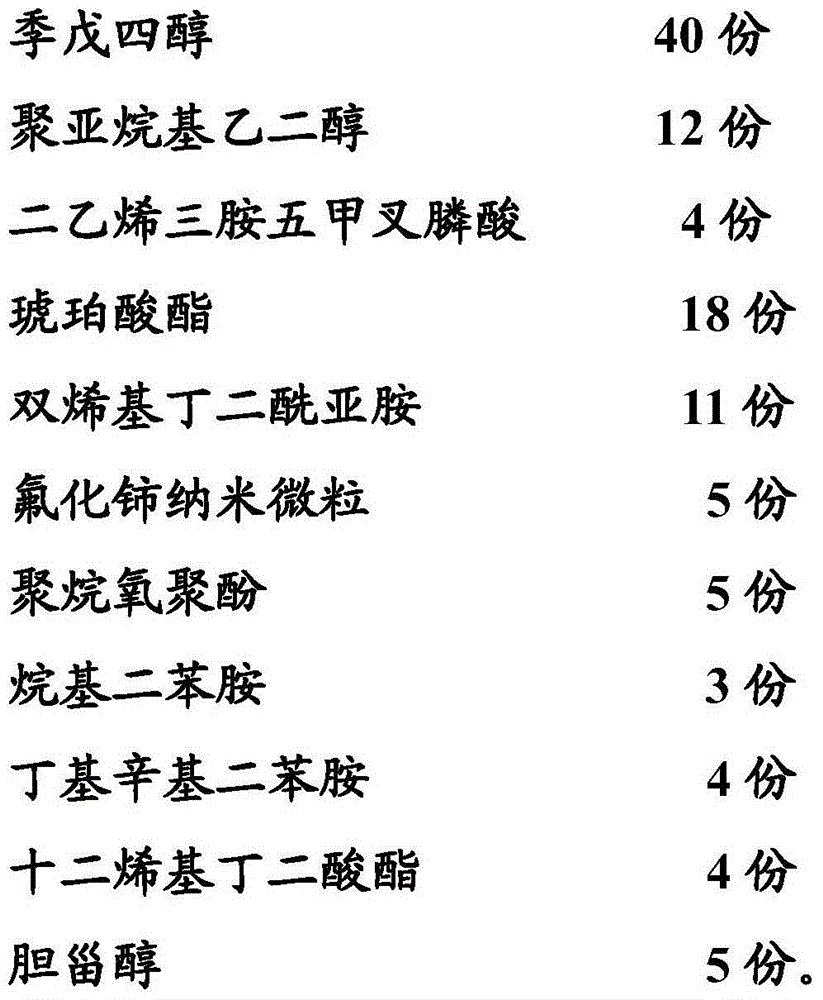

[0012] This embodiment relates to a lubricating oil for bearings, the lubricating oil is composed of the following components in parts by weight:

[0013]

[0014]

[0015] The preparation method of described bearing lubricating oil is made up of following steps:

[0016] Step 1: Take polyalphaolefin, pentaerythritol, and polyalkylene glycol, stir and mix at 800 rpm to obtain a base oil;

[0017] Step 2, take diethylenetriaminepentamethylene phosphonic acid, succinate, dienyl succinyl, cerium fluoride nanoparticles, polyalkoxypolyphenol, alkyl diphenylamine, butyl octyl diphenylamine, Dodecenyl succinate, stirred and mixed at 700rpm to obtain mixture A; then added mixture A to the base oil, stirred at 700rpm to obtain mixture B;

[0018] Step 3: Under the condition of stirring at 700rpm, take cholesterol and add it to the mixture B, then heat it to 83 degrees, keep it warm for 2 hours; cool it to normal temperature, and obtain the lubricating oil for bearings.

[0019]...

Embodiment 2

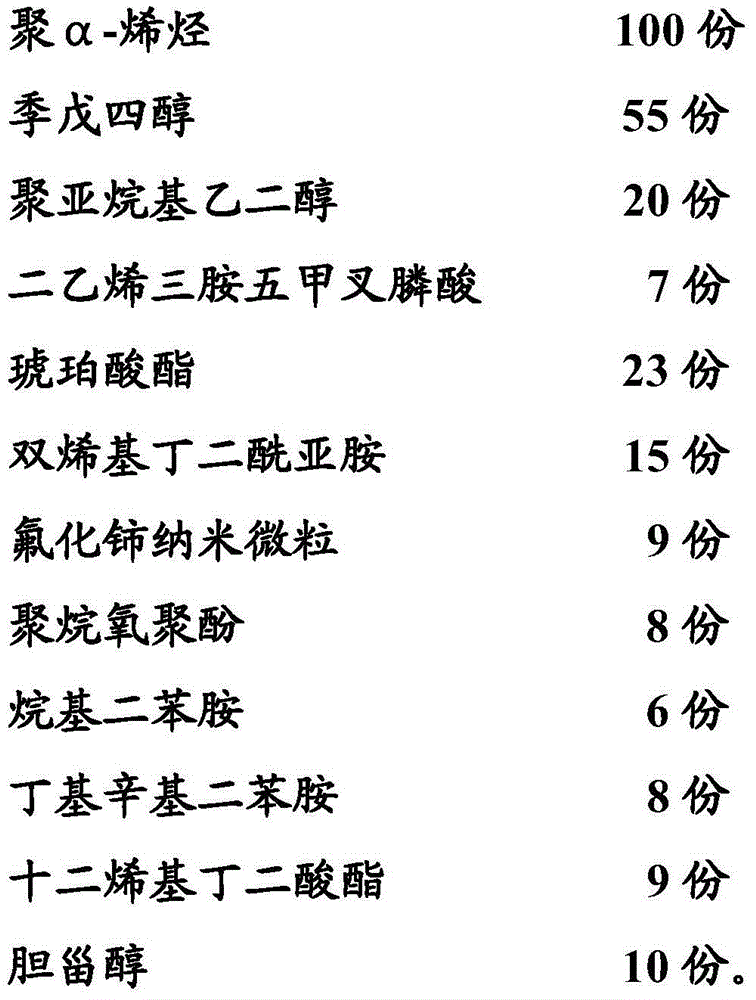

[0021] This embodiment relates to a lubricating oil for bearings, the lubricating oil is composed of the following components in parts by weight:

[0022]

[0023] The preparation method of described bearing lubricating oil is made up of following steps:

[0024] Step 1: Take polyalphaolefin, pentaerythritol, and polyalkylene glycol, stir and mix at 900 rpm to obtain a base oil;

[0025] Step 2, take diethylenetriaminepentamethylene phosphonic acid, succinate, dienyl succinyl, cerium fluoride nanoparticles, polyalkoxypolyphenol, alkyl diphenylamine, butyl octyl diphenylamine, Dodecenyl succinate, stirred and mixed at 900rpm to obtain mixture A; then added mixture A to the base oil, stirred at 900rpm to obtain mixture B;

[0026] Step 3: Under the condition of stirring at 900rpm, take the cholesterol and add it to the mixture B, then heat it to 88 degrees, keep it warm for 5 hours; cool it to normal temperature, and obtain the lubricating oil for bearings.

[0027] The lub...

Embodiment 3

[0029] This embodiment relates to a lubricating oil for bearings, the lubricating oil is composed of the following components in parts by weight:

[0030]

[0031] The preparation method of described bearing lubricating oil is made up of following steps:

[0032] Step 1: Take polyalphaolefin, pentaerythritol, and polyalkylene glycol, stir and mix them evenly at 1000 rpm to obtain a base oil;

[0033] Step 2, take diethylenetriaminepentamethylene phosphonic acid, succinate, dienyl succinyl, cerium fluoride nanoparticles, polyalkoxypolyphenol, alkyl diphenylamine, butyl octyl diphenylamine, Dodecenyl succinate, stirred and mixed uniformly at 1000rpm to obtain mixture A; then added mixture A to the base oil, stirred uniformly at 1000rpm to obtain mixture B;

[0034] Step 3: Under the condition of stirring at 1000rpm, take cholesterol and add it to the mixture B, then heat it to 85 degrees, keep it warm for 3 hours; cool it to normal temperature, and obtain the lubricating oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com