Method for capturing and absorbing suspending impurities in tundish

A technology of tundish and residence time, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of large scope and high cost of equipment transformation, and achieve the effect of reducing molten steel pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

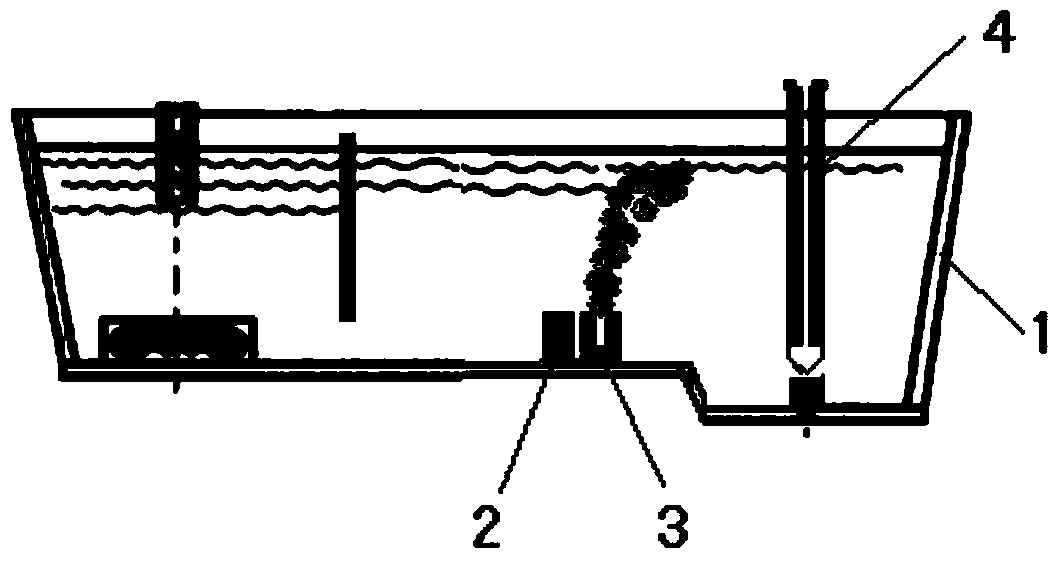

[0012] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described step by step:

[0013] A method for trapping and absorbing suspended inclusions in a tundish. Taking a 30-ton tundish and a steel type SPHC low-silicon aluminum cold-rolled sheet as an example, a CaCO 3 Composition of dike construction boards utilizing CaCO 3 Material thermal burst characteristics, self-generated nucleation centers and bubble power during the pouring process, trap and remove oxides in the continuous casting tundish into the slag, the specific operation steps are as follows:

[0014] 1) As shown in Figure 1, a dike building plate 3 is built on the side of the stopper rod 4 next to the tundish dike 2 at the bottom of the tundish 1, and the size of the dike building plate 3 is 150 mm wide and 750 mm long, and its height is the same as that of the tundish dike The proportion of limestone in the raw material composition of the embankment constructio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com