Growing method of high-crystal quality high-resistance GaN epitaxial layer

A growth method and epitaxial growth technology, which are applied in the field of growing high-resistance GaN epitaxial layers, can solve problems affecting device performance, high dislocation density of high-resistance GaN epitaxial layers, strong electron scattering, etc., to increase stability and reliability, The effect of reducing the content of oxygen impurities and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

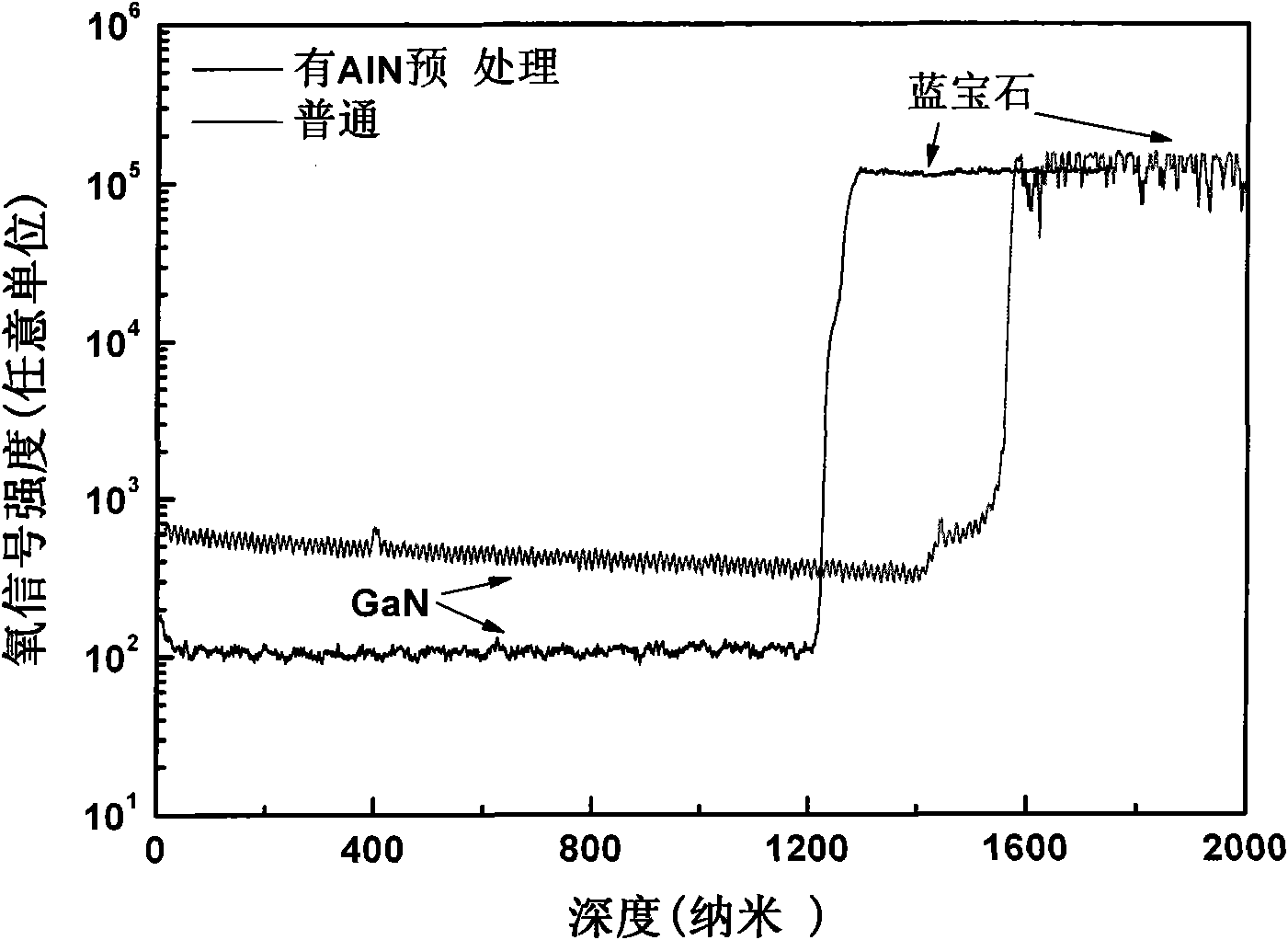

[0040] For the growth of GaN epitaxial layer with high crystal quality and high resistance, 3 batches of samples were prepared according to the following conditions, showing the optimization process of "AlN pretreatment". In addition, 1 batch of samples was prepared according to the conventional conditions (ie, the following 2) and 3) steps were omitted):

[0041] 1) Use MOCVD equipment (3×2”Thomas Swan Close Coupled Showerhead MOCVD), the substrate is a sapphire substrate on the (0001) plane, and the H 2 , the reaction chamber pressure is 300Torr, bake at 1090°C for 5min, and clean the substrate;

[0042] 2) Cool down to 630°C, feed trimethylaluminum and ammonia gas, H 2 as a carrier gas. The reaction chamber pressure is 60Torr, low-temperature AlN is grown, and the growth thicknesses are 10, 16, and 28nm respectively.

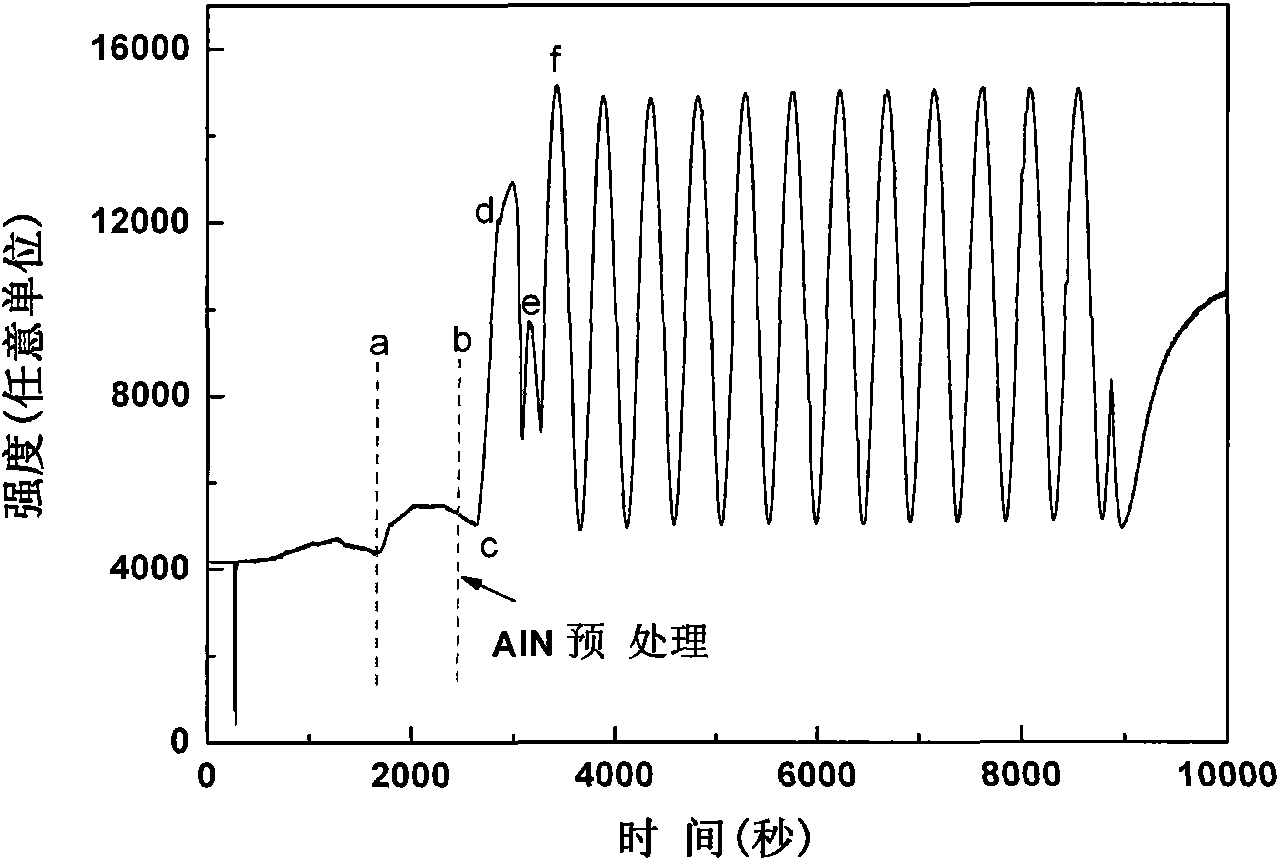

[0043] 3) Keep the pressure of the reaction chamber at 60 Torr, stop feeding trimethylaluminum, continue feeding ammonia gas, raise the temperature to 1100...

Embodiment 2

[0053] High crystal quality and high resistance GaN epitaxial layer growth, keeping the AlN growth conditions unchanged, changing the AlN annealing time, and preparing two furnace samples:

[0054] 1) Use MOCVD equipment (3×2”Thomas Swan Close Coupled Showerhead MOCVD), the substrate is a sapphire substrate on the (0001) plane, and the H 2 , the reaction chamber pressure is 300Torr, bake at 1090°C for 5min, and clean the substrate;

[0055] 2) Cool down to 680°C, feed trimethylaluminum and ammonia, H 2 as a carrier gas. The pressure of the reaction chamber is 75 Torr, the low-temperature AlN is grown, and the growth thickness is 25 nm.

[0056] 3) Stop feeding trimethylaluminum, continue feeding ammonia gas, adjust the pressure of the reaction chamber to 100 Torr, raise the temperature to 1110° C. in 240 seconds, and set the annealing time to 100 and 800 seconds respectively.

[0057] 4) Cool down to 530°C, feed trimethylgallium and ammonia gas, H 2 as a carrier gas. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com