Purification method of electronic-grade octafluorocyclopentene

A technology of octafluorocyclopentene and a purification method, which is applied in the field of purification of electronic grade octafluorocyclopentene, can solve the problem that the adsorbent cannot achieve the purification effect, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

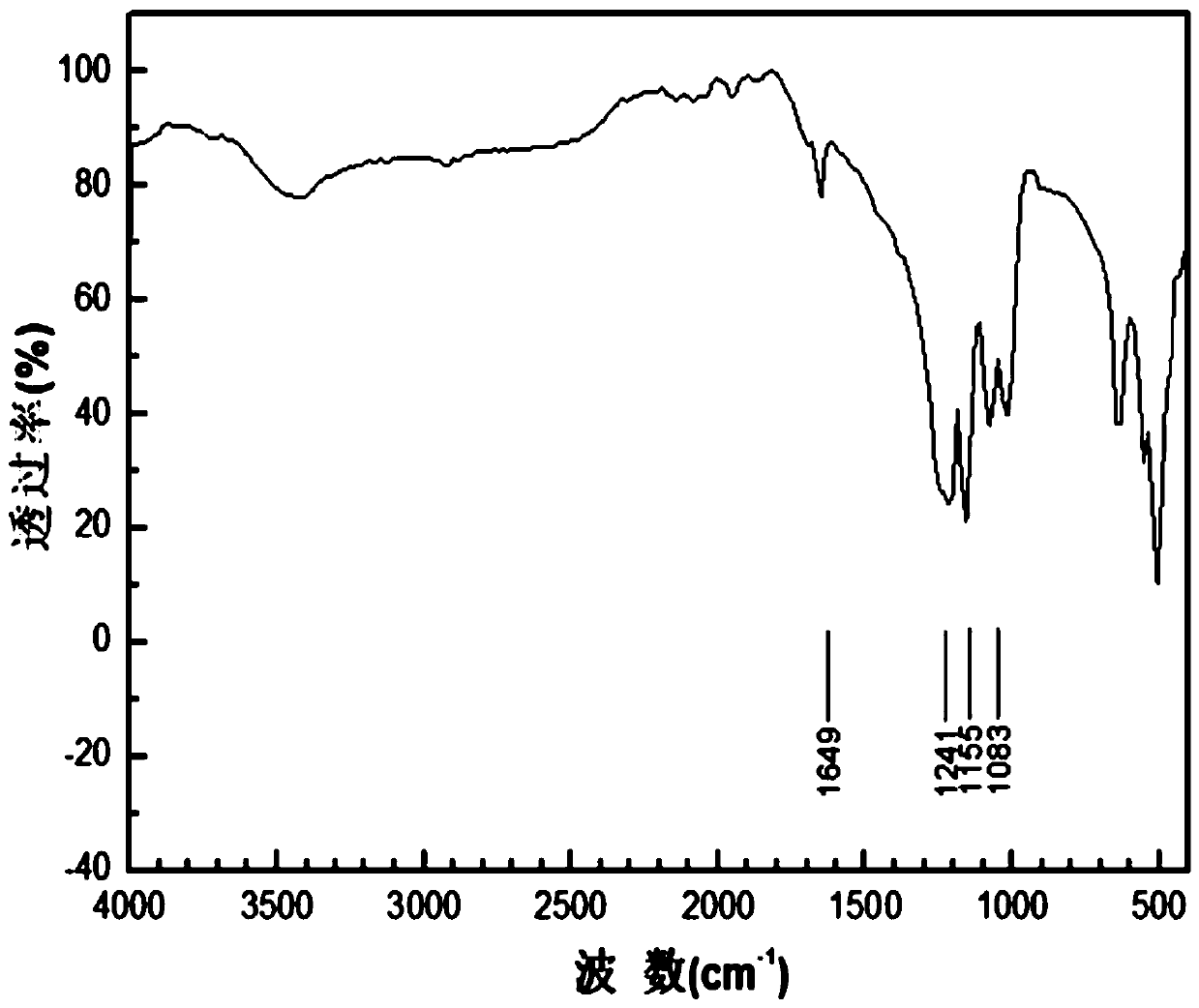

Image

Examples

Embodiment 1

[0027] A kind of purification method of electronic grade octafluorocyclopentene, its specific scheme is as follows:

[0028] Step 1, rectification and purification, the rectification and purification are divided into primary rectification and secondary rectification; the primary rectification is carried out in the first rectification tower, and the primary rectification is carried out at 47°C and 0.2MPa Distillation; The secondary rectification is carried out in the second rectification tower, and the secondary rectification is carried out at 42°C and 0.1MPa;

[0029] Step 2, low-temperature adsorption purification, the low-temperature adsorption purification is carried out at 0°C, characterized in that an ordered mesoporous low-temperature adsorbent is used;

[0030] Step 3, pressurized adsorption purification, pressurize the octafluorocyclopentene after low-temperature adsorption to 0.8 MPa, and then pass it into the gas purifier for pressurized adsorption. The adsorbent use...

Embodiment 2

[0041] A kind of purification method of electronic grade octafluorocyclopentene, its specific scheme is as follows:

[0042] Step 1, rectification purification, the rectification purification is divided into primary rectification and secondary rectification; the primary rectification is carried out in the first rectification tower, and the primary rectification is carried out at 57°C and 0.5MPa Distillation; The secondary rectification is carried out in the second rectification tower, and the secondary rectification is carried out at 52 ° C and 0.3 MPa;

[0043] Step 2, low-temperature adsorption purification, the low-temperature adsorption purification is carried out at 5°C, characterized in that an ordered mesoporous low-temperature adsorbent is used;

[0044] Step 3, pressurized adsorption purification, pressurize the octafluorocyclopentene after low-temperature adsorption to 1.6 MPa, and then pass it into the gas purifier for pressurized adsorption. The adsorbent used for ...

Embodiment 3

[0055] A kind of purification method of electronic grade octafluorocyclopentene, its specific scheme is as follows:

[0056] Step 1, rectification purification, the rectification purification is divided into primary rectification and secondary rectification; the primary rectification is carried out in the first rectification tower, and the primary rectification is carried out at 77°C and 0.8MPa Distillation; The secondary rectification is carried out in the second rectification tower, and the secondary rectification is carried out at 62 ° C and 0.4 MPa;

[0057] Step 2, low-temperature adsorption purification, the low-temperature adsorption purification is carried out at 10°C, which is characterized in that an ordered mesoporous low-temperature adsorbent is used;

[0058] Step 3, pressurized adsorption purification, pressurize the octafluorocyclopentene after low-temperature adsorption to 2.4 MPa, and then pass it into the gas purifier for pressurized adsorption. The adsorbent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com