Apparatus for preparing polysilicon through electron beam deoxygenation and preliminary ingot casting coupling, and method thereof

A technology of polysilicon and electron beams, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of increasing overall investment and low production efficiency, and achieve the reduction of total energy consumption, improvement of production efficiency, and efficient removal of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

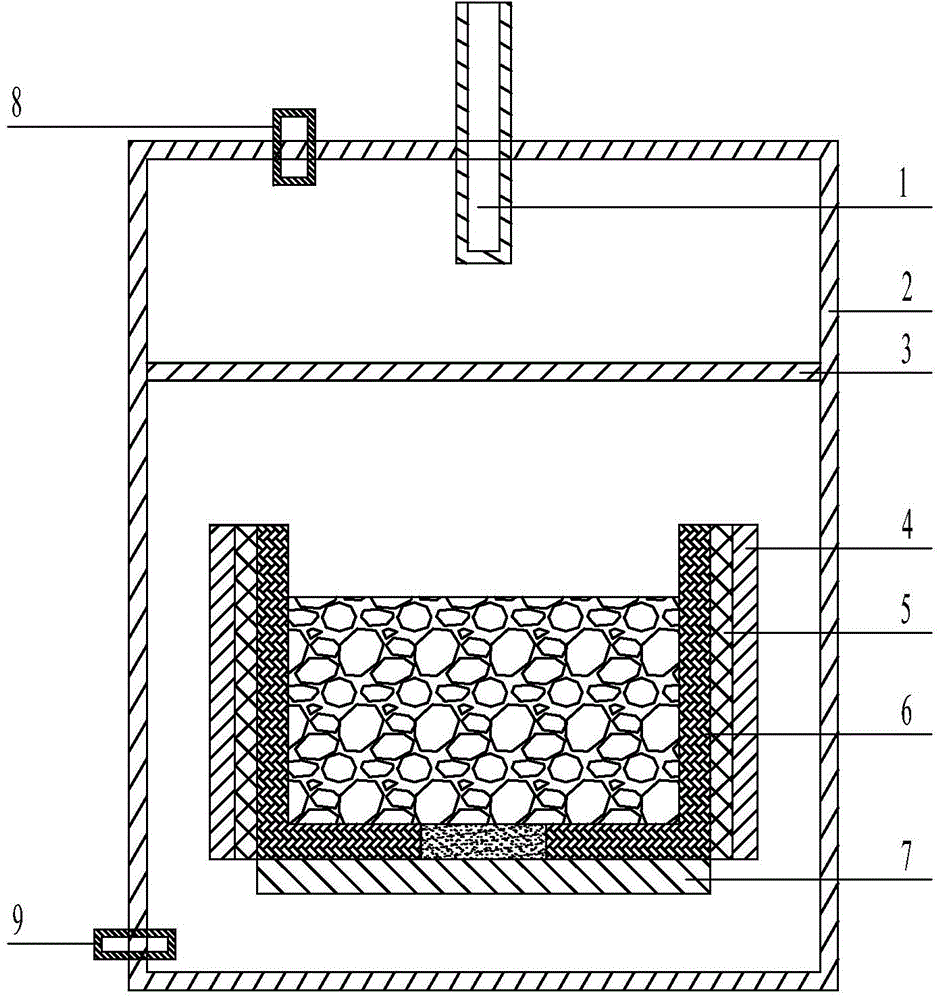

[0036] An electron gun 1 is connected to the top of the furnace body 2, an inflatable valve 8 is opened at the upper end of the side, and an air release valve 9 is opened at the lower end. A quartz crucible 6 is placed on the water-cooled copper base 7 in the furnace body 2, and the outer wall of the quartz crucible 6 is from the inside to the inside. A graphite heater 5 and a graphite carbon felt 4 are surrounded in sequence on the outside, and a thermal insulation cover 3 is installed on the top of the graphite carbon felt. A hole is opened at the central position of the bottom of the quartz crucible 6, and the area of the hole is 20% of the bottom area of the quartz crucible.

Embodiment 2

[0038] Using the device in Example 1 to carry out electron beam deoxidation and preliminary ingot coupling to prepare polysilicon:

[0039] (1) Loading: crush 500kg of polysilicon ingot bottom material with an oxygen content of 0.008%, wash and dry it, put it into the quartz crucible 6, and close the vacuum device cover 3.

[0040](2) Vacuuming: Turn on the cooling circulating water device of the equipment, and supply cooling circulating water to the equipment; supply cooling circulating water to the water-cooled copper base 7 . Turn on the vacuum pump of furnace body 2, firstly use the mechanical pump and Roots pump in the vacuum pump group to pump the vacuum degree of furnace body 2 to 5×10 -2 Pa, the vacuum degree of electron gun 1 is pumped to 5×10 -3 Pa, turn off the vacuum pump unit.

[0041] (3) Melting: Adjust the power of the graphite heater 5 to 10kW to make the temperature of the silicon material reach 1450°C, so that the silicon material is completely melted.

...

Embodiment 3

[0047] Using the device in Example 1 to carry out electron beam deoxidation and preliminary ingot coupling to prepare polysilicon:

[0048] (1) Loading: crush 500kg of polysilicon ingot bottom material with an oxygen content of 0.006%, wash and dry it, put it into the quartz crucible 6, and close the vacuum device cover 3.

[0049] (2) Vacuuming: Turn on the cooling circulating water device of the equipment, and supply cooling circulating water to the equipment; supply cooling circulating water to the water-cooled copper base 7 . Turn on the vacuum pump of the furnace body 2, first use the mechanical pump and Roots pump in the vacuum pump group to pump the vacuum degree of the furnace body 2 to 4×10 -2 Pa, electron gun 1 vacuum pumped to 4 × 10 -3 Pa, turn off the vacuum pump unit.

[0050] (3) Melting: Adjust the power of the graphite heater 5 to 25kW to make the temperature of the silicon material reach 1550°C and completely melt the silicon material.

[0051] (4) Electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com