High-purity silicon carbide powder and preparation method therefor

A high-purity silicon carbide powder, silicon carbide powder technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of high-purity silicon carbide powder particle size distribution range, difficult impurity content, high toxicity, etc., to achieve good decarbonization effect , low degree of oxidation, controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] According to one embodiment of the present application, the preparation method of high-purity silicon carbide powder comprises the following steps:

[0046] 1) One-time synthesis: Mix high-purity carbon powder and high-purity silicon powder evenly under vacuum conditions at a molar ratio of 1:1, place them in a graphite crucible, and place them in a medium-frequency induction heating furnace; grow in a medium-frequency induction heating furnace The chamber is evacuated to 1 x 10 -2 to 1×10 -3 Pa and raise the temperature to 1000-1500°C, stabilize for 10-15h to obtain β-silicon carbide powder;

[0047] 2) Secondary synthesis: continue to heat up to 1900-2200°C, and fill with high-purity argon and / or high-purity helium until the pressure in the growth chamber is stable at 800-900mbar, and keep the temperature and pressure stable for 20-40h of conversion reaction, Obtain α silicon carbide powder;

[0048] 3) Recrystallization: Evacuate again until the pressure in the gr...

Embodiment 1

[0054] The preparation of embodiment 1 high-purity silicon carbide powder 1#

[0055] 1) One-time synthesis: Mix high-purity carbon powder and high-purity silicon powder evenly under vacuum conditions at a molar ratio of 1:1, place them in a graphite crucible, and place them in a medium-frequency induction heating furnace; grow in a medium-frequency induction heating furnace The chamber is evacuated to 1 x 10 - 2 Pa and raise the temperature to 1000°C, and stabilize for 10 hours to obtain β-silicon carbide powder;

[0056] 2) Secondary synthesis: continue to raise the temperature to 1900°C, and fill it with high-purity argon and / or high-purity helium until the pressure in the growth chamber is stable at 800mbar, and keep the temperature and pressure stable for 20 hours of conversion reaction to obtain α-silicon carbide powder;

[0057] 3) Recrystallization: Evacuate again until the pressure in the growth chamber is stable at 10mbar, and raise the temperature to 2800°C, maint...

Embodiment 2

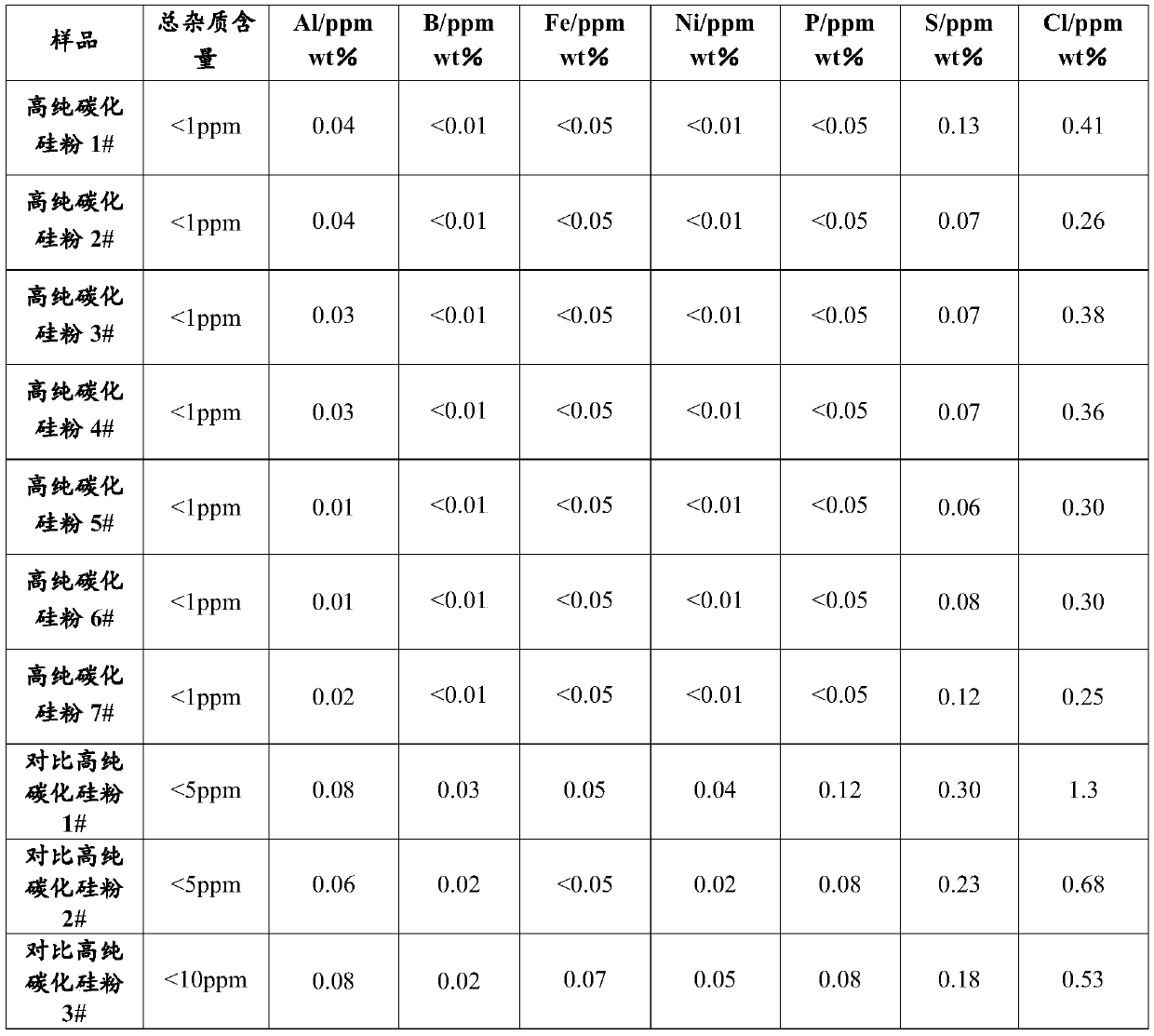

[0060] Embodiment 2 Preparation of high-purity silicon carbide powder 1#-7#, comparative silicon carbide powder D1#-D3#

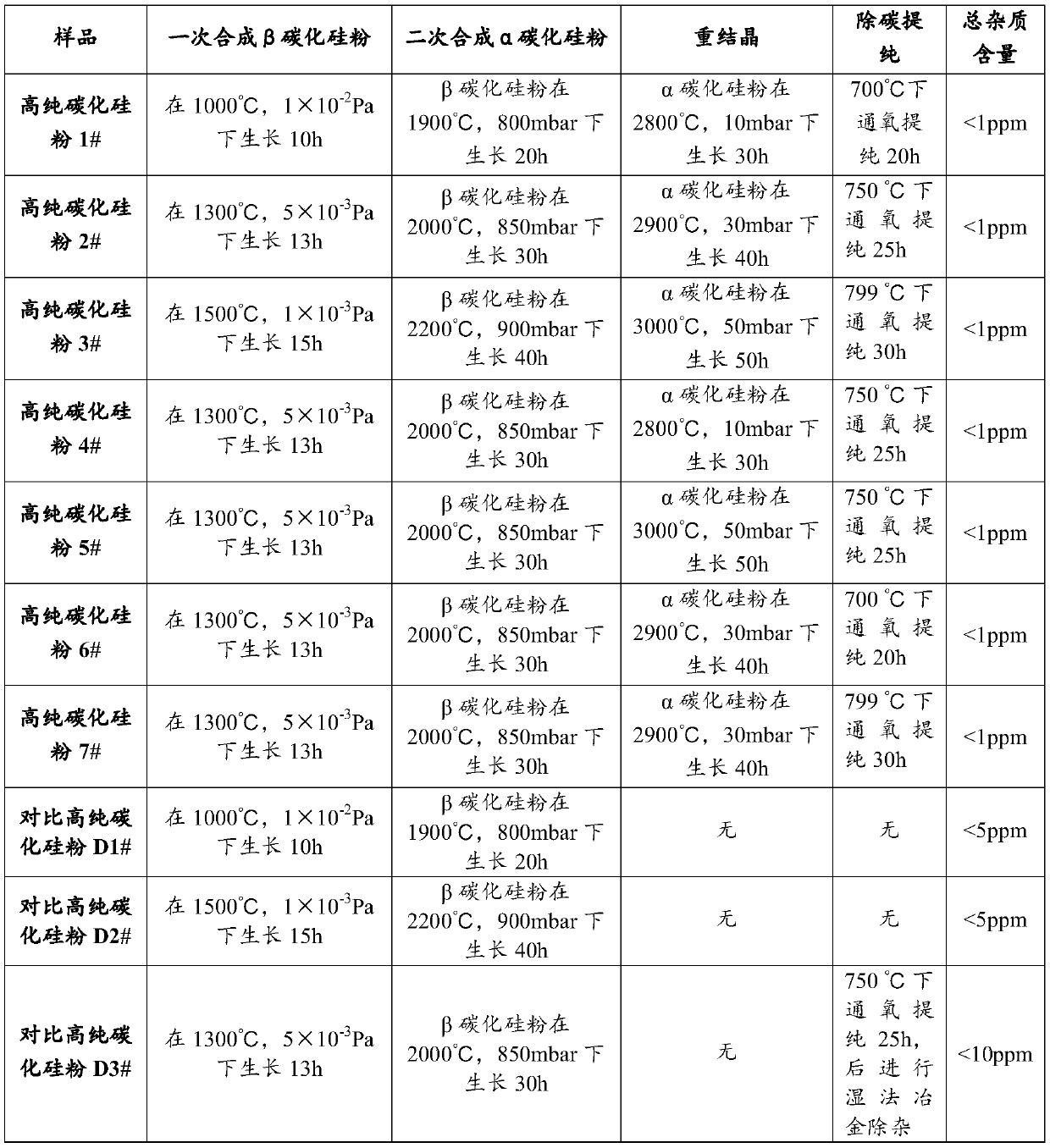

[0061] According to the preparation method of the high-purity silicon carbide powder 1# of Example 1, high-purity silicon carbide powder 1#-7# and contrast silicon carbide powder D1#-D3# were prepared respectively, which were compared with the preparation of high-purity silicon carbide powder 1# The differences in the methods are shown in Table 1.

[0062] Table 1

[0063]

[0064] Compared with the hydrometallurgical impurity removal in high-purity silicon carbide powder D3#, the mixed strong acid of hydrofluoric acid and hydrochloric acid is used to soak and then filter and wash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com