Crucible for polycrystalline silicon ingot, production method of crucible as well as polycrystalline silicon ingot and production method thereof

A polysilicon and crucible technology, applied in the field of polysilicon production equipment, can solve the problems of polysilicon ingots with poor minority carrier life and the inability to effectively reduce metal impurities and oxygen impurity pollution at the same time, so as to reduce the area with poor minority carrier life, accelerate the coagulation time, and improve the firmness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

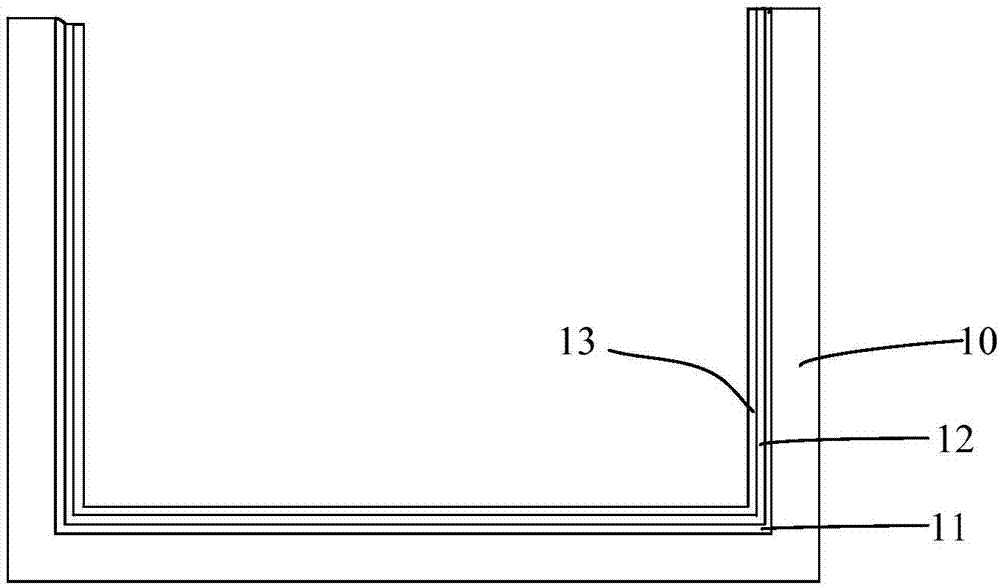

[0067] This embodiment provides a method for preparing a crucible for polycrystalline silicon ingots, comprising the following steps:

[0068] 1) Prepare barrier layer slurry: mix quartz powder with a purity greater than 4N (above 99.99%) with water to prepare a high-purity quartz slurry; mix the high-purity quartz slurry with silica sol at a mass ratio of 3:1, Obtain the barrier layer slurry; Wherein, the silica sol is purchased from Suzhou Nadi Company; SiO in the silica sol 2 The particle size is nanoscale, and the mass concentration is 30wt%; the mass concentration of quartz powder in the high-purity quartz slurry is 70wt%, and its particle size is 5 μm;

[0069] Prepare gettering layer slurry: get 100g of polycrystalline silicon powder (with a particle size of 10 μm) and 50 g of silicon nitride powder (with a particle size of 1-2 μm) and polycrystalline silicon powder (both of which have a purity of 99.99% above), add 300g of pure water, and mix uniformly to obtain the g...

Embodiment 2

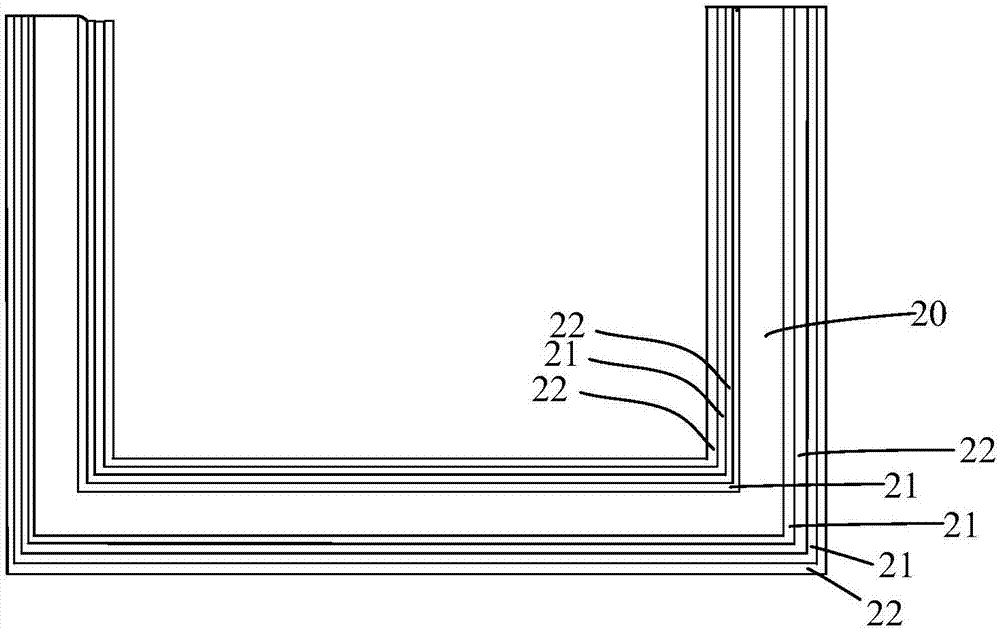

[0076] This embodiment provides a method for preparing a crucible for polycrystalline silicon ingots, comprising the following steps:

[0077] 1) Preparation of gettering layer slurry: Take 100g of polycrystalline silicon powder (with a particle size of 10 μm), 50 g of silicon nitride powder (with a particle size of 1-2 μm) and polycrystalline silicon powder (both with a purity of 99.99%), add 300g of pure water, and mix evenly to obtain the gettering layer slurry;

[0078] Get 400g of high-purity silicon nitride powder (a particle size of 0.8 μm, a product produced by Japan UBE Company, wherein the nitrogen content > 38wt%, and the oxygen content < 2.0wt%), add it to 800g of pure water, stir evenly to obtain nitrogen Si layer slurry;

[0079] 2) Take a cuboid quartz crucible body with a model size of 840mm×840mm×480mm for use. The crucible body includes a base and 4 side walls extending upward from the base, and the base and 4 side walls together form a storage space;

[00...

Embodiment 3

[0083] This embodiment provides a method for preparing a crucible for polycrystalline silicon ingots, comprising the following steps:

[0084] 1) Prepare barrier layer slurry: mix quartz powder (with a particle size of about 6 μm) with a purity greater than 4N (99.99%) and water to prepare a pure quartz slurry with a mass concentration of 70 wt%, and use it as a barrier layer slurry material;

[0085] Prepare gettering layer slurry: get 100g of polycrystalline silicon powder (with a particle size of 10 μm) and 50 g of silicon nitride powder (with a particle size of 1-2 μm) and polycrystalline silicon powder (both of which have a purity of 99.99% above), add 300g of pure water, and mix uniformly to obtain the getter layer slurry;

[0086] Take 400g of high-purity silicon nitride powder (the particle size is 50um, a product produced by Japan UBE Company, wherein the nitrogen content> 38wt%, oxygen content<2.0wt%), add it to 800g pure water, stir to obtain nitriding Silicon lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com