Method and device for circulating hydrogen repurification

A hydrogen and tail gas technology, applied in hydrogen separation, using solid contact hydrogen separation, etc., can solve the problem that impurities are difficult to effectively remove, and achieve the effect of thorough impurity removal process, breaking through technical blockade, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

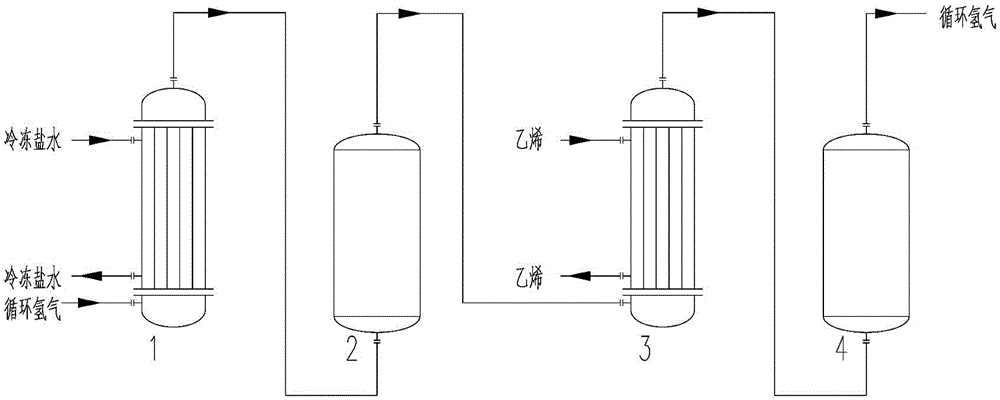

Embodiment 1

[0024] A method for repurifying circulating hydrogen. The circulating hydrogen comes from the recovered hydrogen in the dry recovery process of reducing tail gas. The circulating hydrogen is first passed into the hydrogen cooler 1 for cooling, the hydrogen is cooled to 20°C, and the cooled circulating hydrogen is passed through into the primary adsorption reaction column 2 to remove impurities mainly containing boron elements; the circulating hydrogen after the primary adsorption reaction is passed into the hydrogen deep cooler 3 to cool the hydrogen to -80°C, and the cooled circulating hydrogen enters the secondary The first-stage adsorption reaction column (4) removes impurities mainly containing phosphorus elements, and the adsorption temperature is -80°C. Hydrogen cooler 1 is a tube-and-tube heat exchanger, and the tube side uses circulating hydrogen, and the cooling medium on the shell side is frozen brine at a temperature of -10°C; hydrogen cryocooler 3 is a tube-and-tube...

Embodiment 2

[0026] A method for repurifying circulating hydrogen, the circulating hydrogen comes from the recovered hydrogen in the dry recovery process of reducing tail gas, the circulating hydrogen is first passed into the hydrogen cooler 1 for cooling, the hydrogen is cooled to 0°C, and the cooled circulating hydrogen is passed through into the primary adsorption reaction column 2 to remove impurities mainly containing boron elements; the circulating hydrogen after the primary adsorption reaction is passed into the hydrogen deep cooler 3 to cool the hydrogen to -70°C, and the cooled circulating hydrogen enters the secondary The first-stage adsorption reaction column 4 removes impurities mainly containing phosphorus elements, and the adsorption temperature is -88°C. Hydrogen cooler 1 is a tube-and-tube heat exchanger, and the tube side uses circulating hydrogen, and the cooling medium on the shell side is frozen brine at a temperature of -12°C; hydrogen cryocooler 3 is a tube-and-tube he...

Embodiment 3

[0028] A device for repurifying circulating hydrogen. The top of the hydrogen cooler 1 is connected to the bottom of the primary adsorption reaction column 2 through the feeding pipe, and the top of the primary adsorption reaction column 2 is connected to the bottom of the hydrogen deep cooler 3 through the feeding pipe. The top of the cooler 3 is connected to the bottom of the secondary adsorption reaction column 4 through a feed pipe. Both the primary adsorption reaction column 2 and the secondary adsorption reaction column 4 are of fixed bed structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com