Novel sweeping and absorbing integrated cleaning mechanism

A cleaning mechanism and integrated technology, which is applied in the field of new sweeping and suction integrated cleaning mechanism, can solve the problems of high energy consumption, narrow application range, air pollution, etc., and achieve the effect of overcoming single structure, novel and reasonable structure, and improving environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

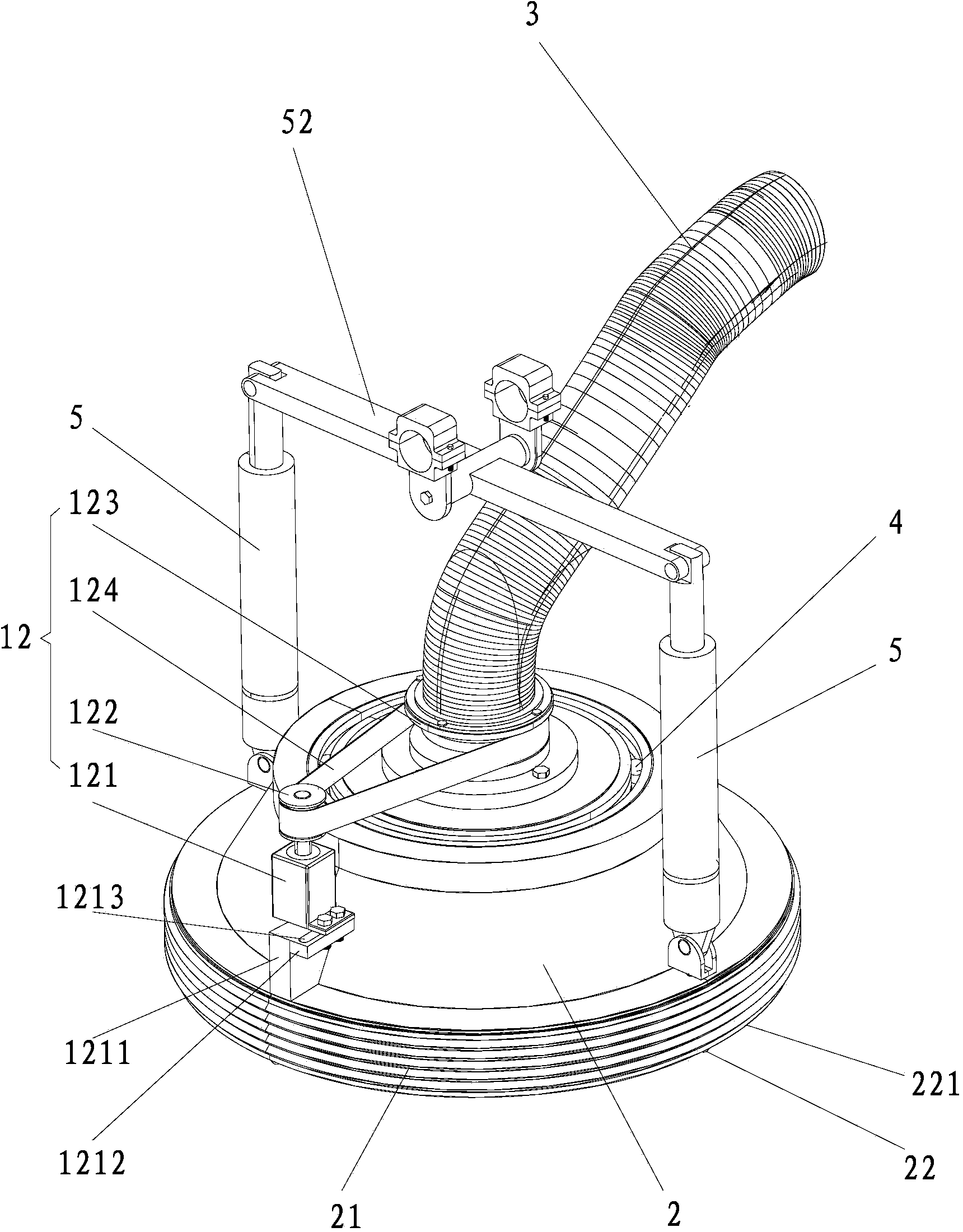

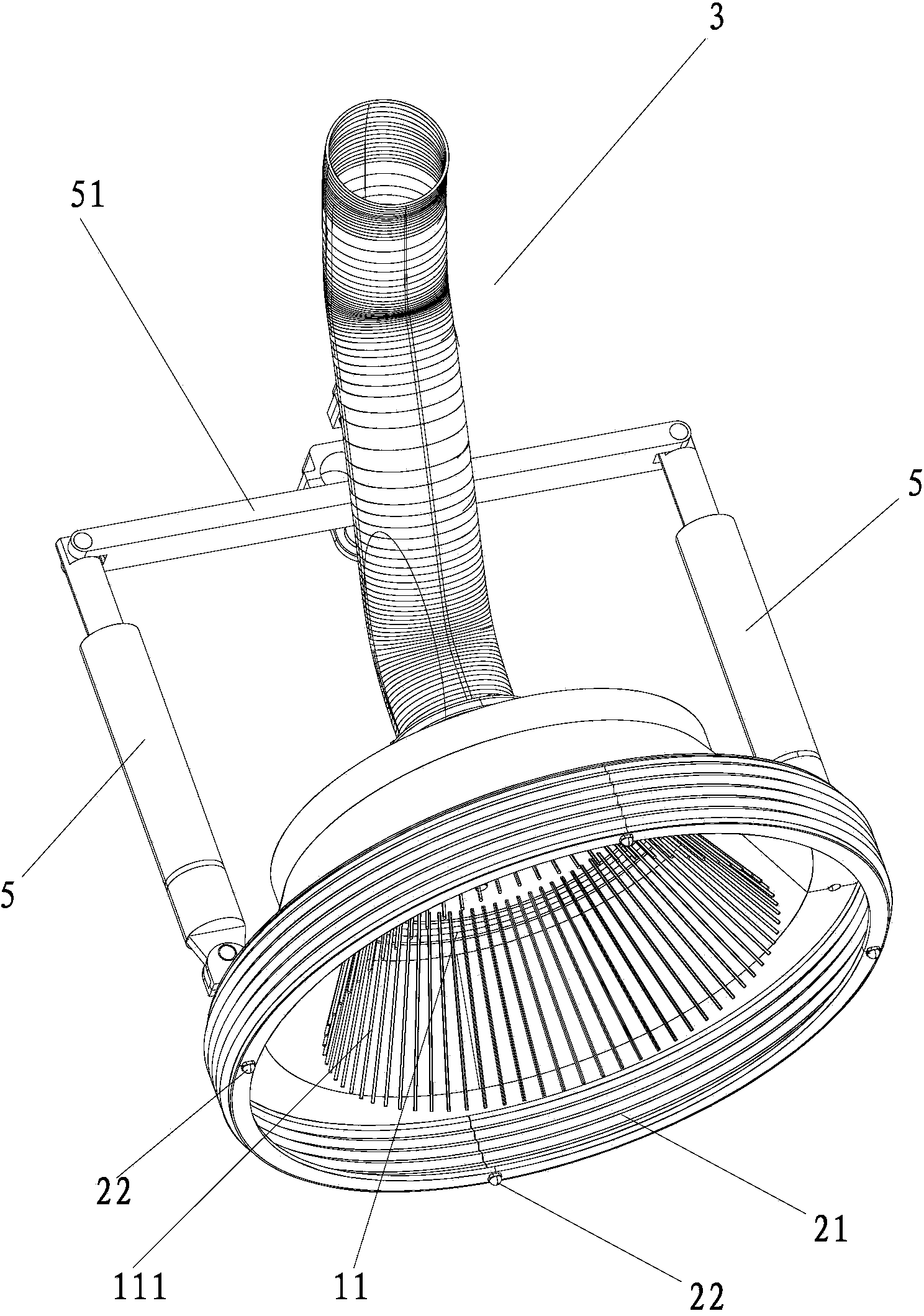

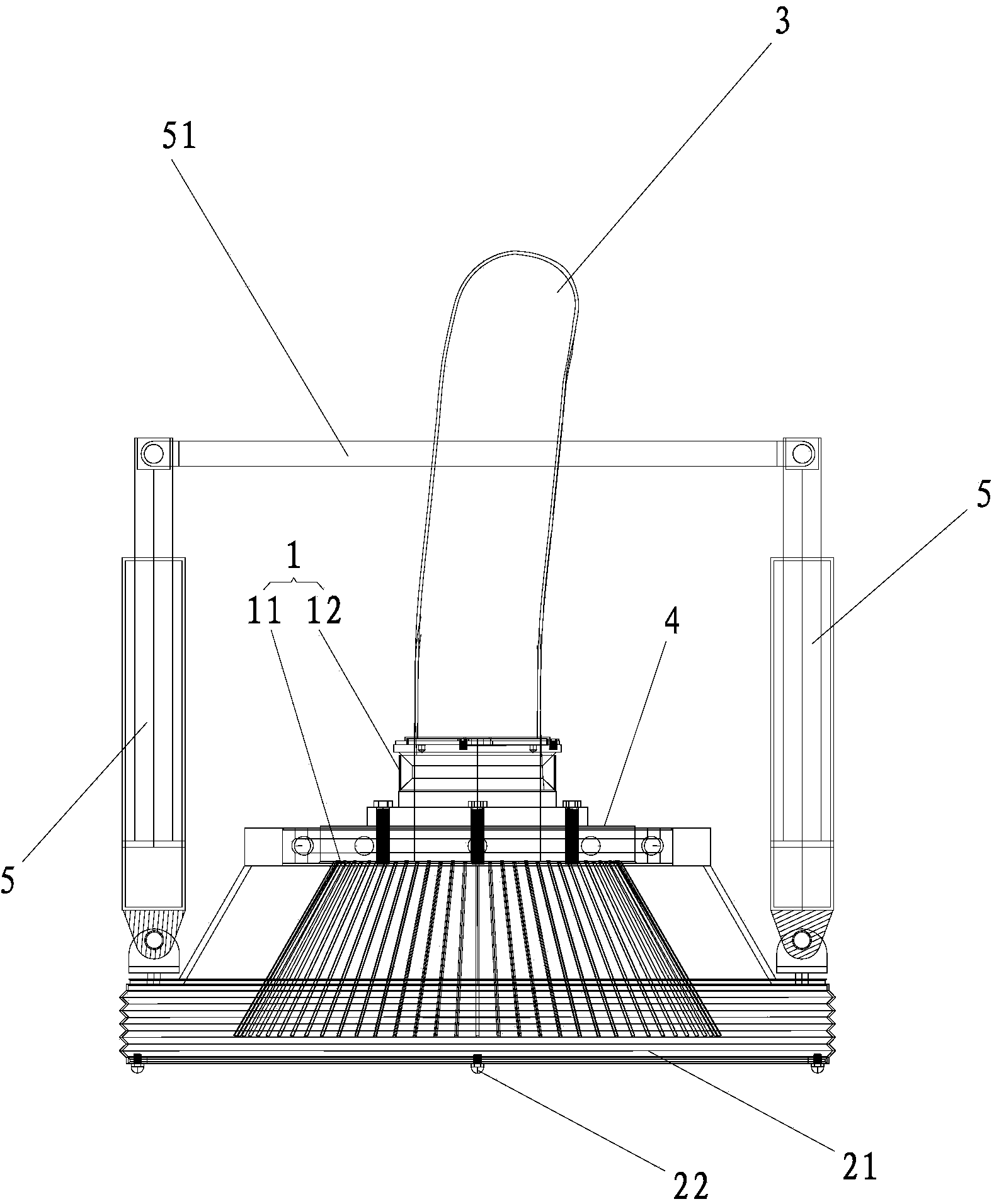

[0032] A new type of sweeping and suction integrated cleaning mechanism of the present invention, such as Figure 1-4 As shown, it includes a rotating cleaning brush 1, a housing 2 and a suction pipe 3.

[0033] The rotating cleaning brush 1 is carried by the cleaning vehicle. The casing 2 is covered outside the rotating cleaning brush 1. The casing 2 is in soft contact with the ground, and a suction pipe 3 is connected above the casing 2. The soft contact form can ensure that the casing 2 does not It is damaged by the ground, and it can ensure that the gap between the shell 2 and the ground is small, so that a negative pressure is formed in the shell 2, which is beneficial to the suction of the suction pipe 3. The present invention combines the rubbish sweeping and suction structures together, and the rotating cleaning brush 1 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com