Plate-shell heat exchanger

A heat exchanger, plate and shell technology, applied in the field of heat exchange equipment, can solve the problems of low heat transfer efficiency, poor pressure bearing capacity, large structure, etc., achieve high heat transfer efficiency, overcome poor pressure bearing capacity, and save investment and the effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

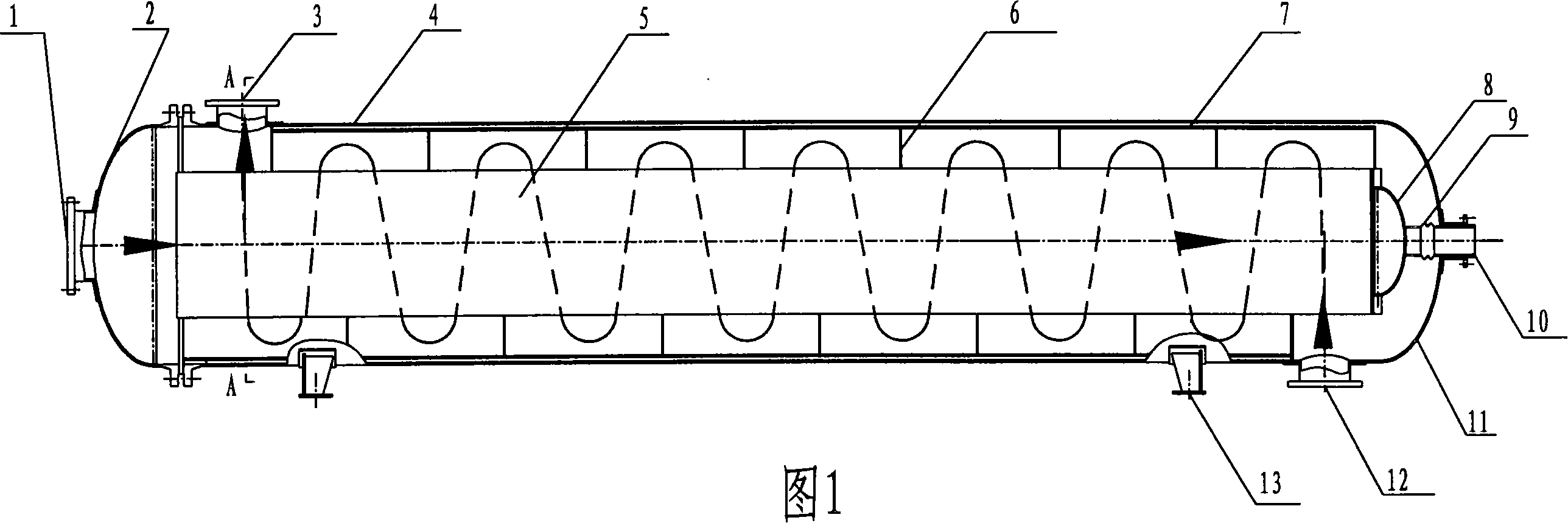

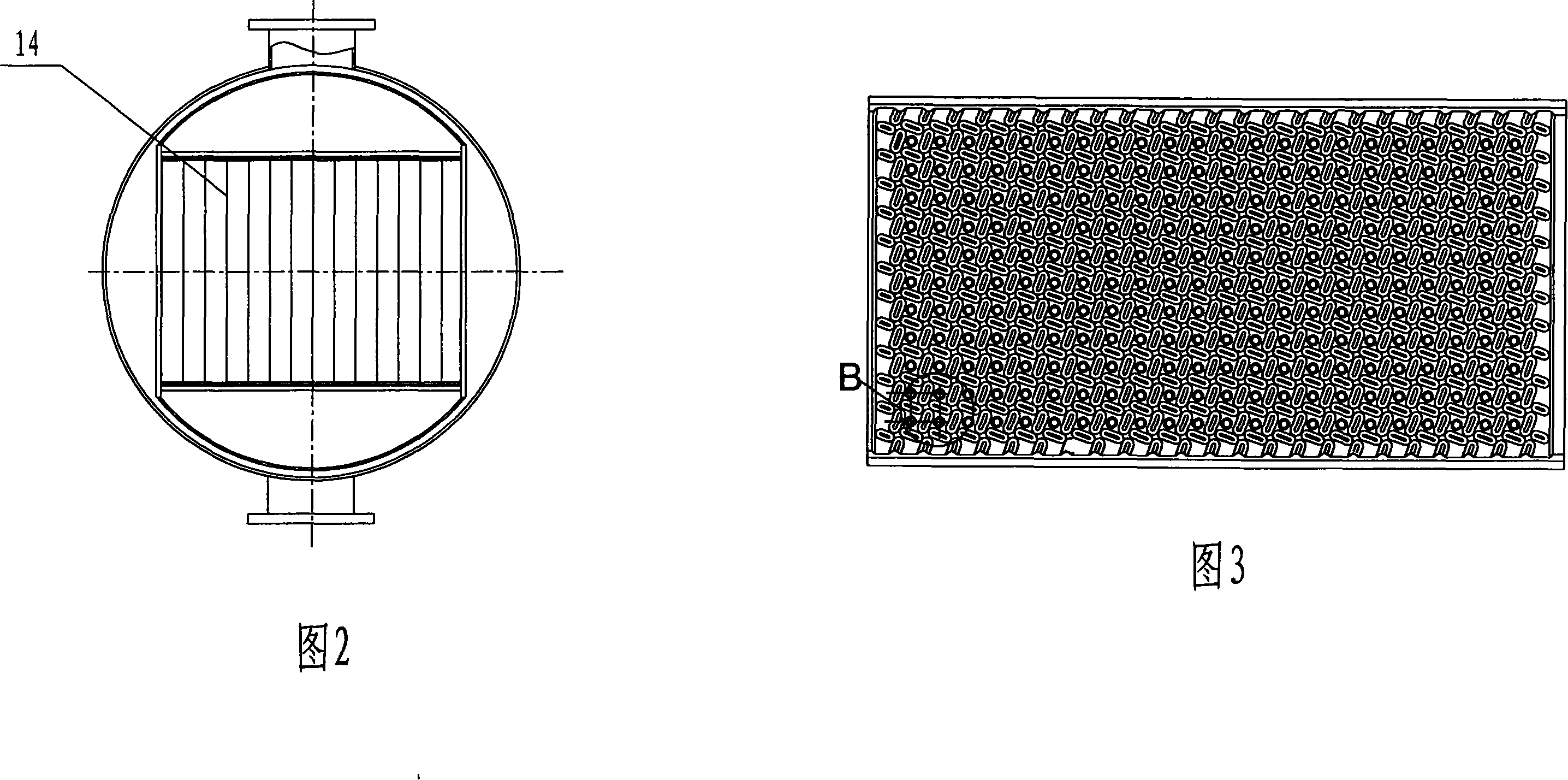

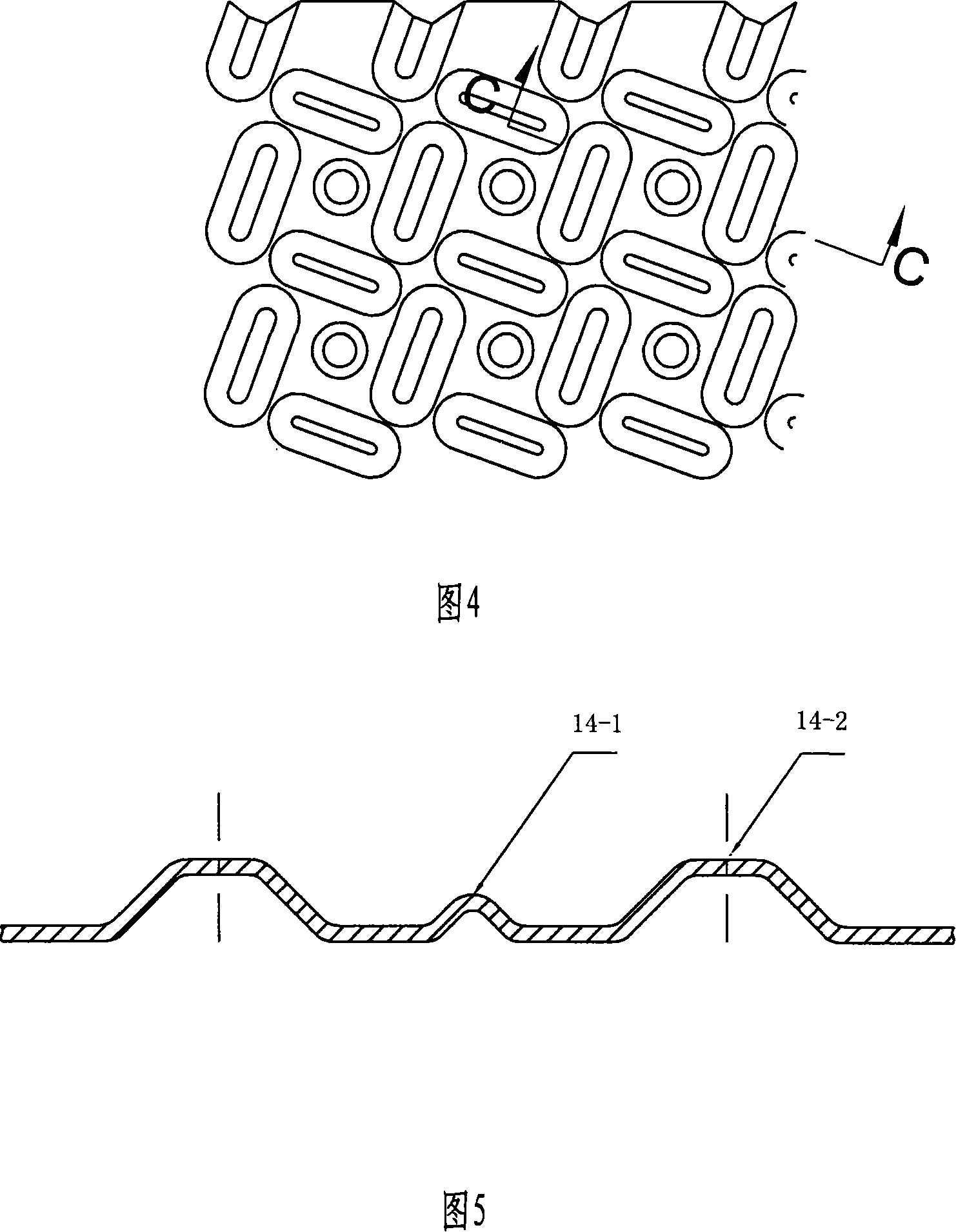

[0020] Specific embodiments of the present invention refer to accompanying drawings. The structure diagram in Figure 1 reflects the general assembly diagram of the plate and shell heat exchanger. The plate and shell heat exchanger has a shell 4, and the two ends of the shell 4 are the left and right side heads 2, 11 of the shell. At the left and right ends of the shell 4 are the tube side inlet 1 and the tube side outlet 10, which are respectively connected to the two ends of the tube side flow channel of the plate tube bundle 5 through the expansion joint 9 and the tube side outlet box 8. According to the customary name of the heat exchanger, the flow channel parallel to the axis of the shell is called the tube side. The purpose of connecting the outlet pipe box of the tube side with an outlet pipe with an expansion joint is that the tube bundle can be freely expanded and contracted in the shell by means of the expansion joint plate. Shell-side inlets and outlets 12 and 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com