A high-strength and toughness cast aluminum-silicon alloy and its preparation method and application

A technology of casting aluminum-silicon alloy and aluminum-silicon alloy, which is applied in the field of high-strength and toughness casting aluminum-silicon alloy and its preparation, can solve the problems of unsatisfactory strength and plasticity, insufficient fracture toughness, low elongation, etc., and achieve uniform structure and composition properties, improve casting fluidity, improve plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

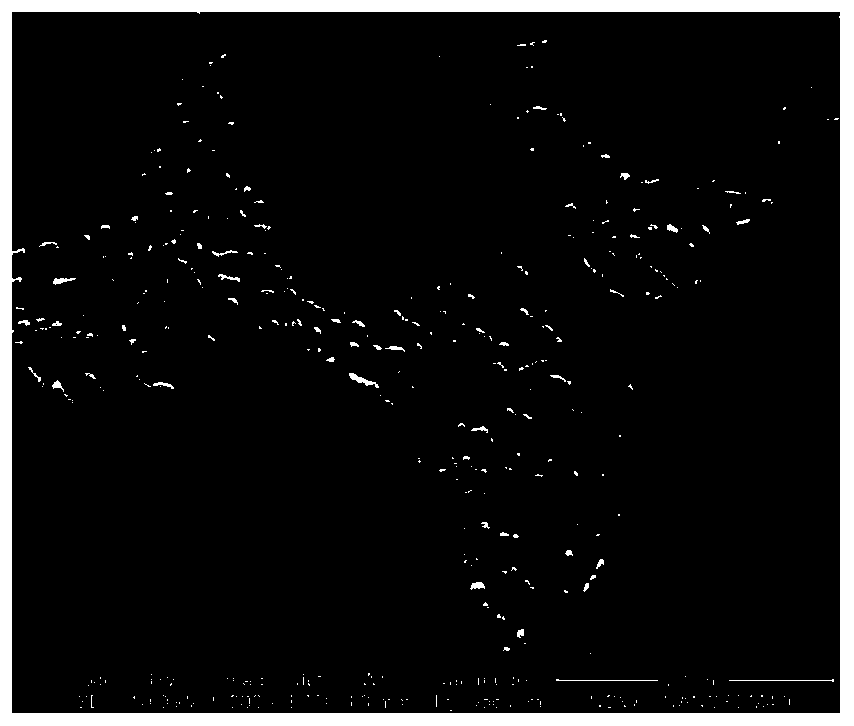

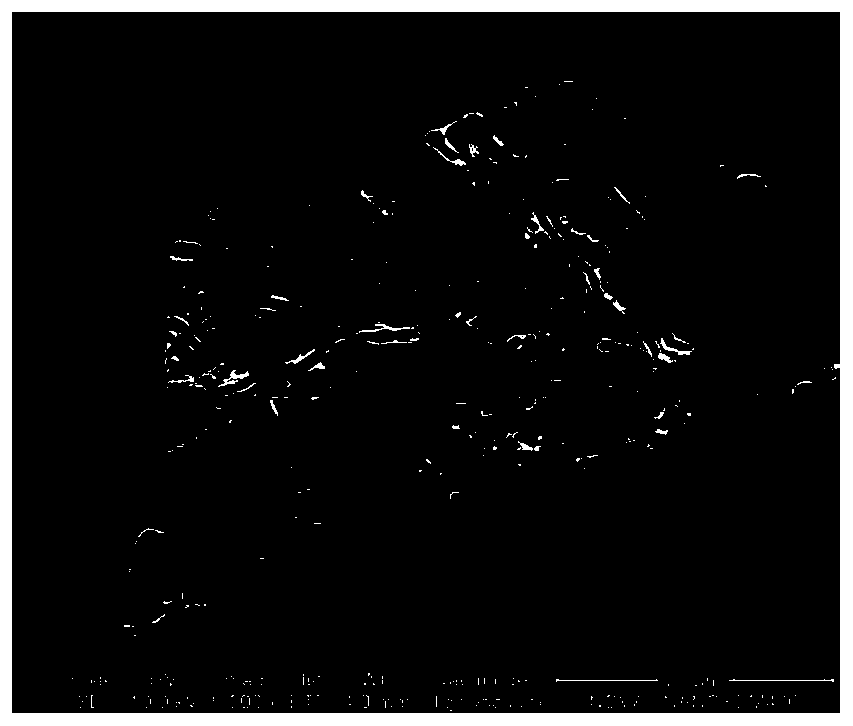

Image

Examples

preparation example Construction

[0041] The preparation method of the high-strength and toughness cast aluminum-silicon alloy provided by the present invention comprises the following steps in sequence:

[0042] The first step: according to the composition and mass percentage of the high-strength cast aluminum-silicon alloy, select aluminum source, silicon source, magnesium source, titanium source, strontium source, lanthanum source and cerium source as raw materials for batching;

[0043] The aluminum source is an aluminum ingot with an aluminum content of 99.7%, the magnesium source is a magnesium ingot with a magnesium content of 99.95%, the silicon source is an AlSi20 alloy, the titanium source is an AlTi10 alloy, the strontium source is an AlSr10 alloy, the lanthanum source is an AlLa5 alloy, and the cerium source is an AlSi20 alloy. AlCe5 alloy;

[0044] Step 2: Heat and melt the aluminum source at 760-780°C, then add silicon source and magnesium source, stir and melt to form aluminum alloy liquid;

[...

Embodiment 1

[0054] The cast aluminum-silicon alloy is composed of the following mass percentages: Si 7.7%, Mg 0.42%, Fe 0.12%, Ti 0.16%, Sr 0.018%, La 0.036%, Ce 0.024%, and the rest are Al and unavoidable impurity elements, The individual content of impurity elements is less than 0.05%, and the total amount is less than 0.15%. The preparation method includes the following steps in sequence:

[0055] The first step: according to the composition and mass percentage of the cast aluminum-silicon alloy, aluminum ingots with an aluminum content of 99.7%, magnesium ingots with a magnesium content of 99.95%, AlSi20 alloys, AlTi10 alloys, AlSr10 alloys, AlLa5 alloys and AlCe5 alloys are selected as raw materials. Ingredients;

[0056] Step 2: Heat and melt the aluminum ingot at 770°C, then add magnesium ingot and AlSi20 alloy, stir and melt to form aluminum alloy liquid;

[0057] The third step: adding AlTi10 alloy, AlSr10 alloy, AlLa5 alloy and AlCe5 alloy to the aluminum alloy liquid for refin...

Embodiment 2

[0063] The cast Al-Si alloy is composed of the following mass percentages: Si 7%, Mg 0.5%, Fe 0.1%, Ti0.2%, Sr 0.01%, La 0.06%, Ce 0.04%, and the rest are Al and unavoidable impurity elements , the individual content of impurity elements is less than 0.05%, and the total amount is less than 0.15%; the preparation method includes the following steps in sequence:

[0064] The first step: according to the composition and mass percentage of the cast aluminum-silicon alloy, aluminum ingots with an aluminum content of 99.7%, magnesium ingots with a magnesium content of 99.95%, AlSi20 alloys, AlTi10 alloys, AlSr10 alloys, AlLa5 alloys and AlCe5 alloys are selected as raw materials. Ingredients;

[0065] Step 2: Heat and melt the aluminum ingot at 780°C, then add magnesium ingot and AlSi20 alloy, stir and melt to form aluminum alloy liquid;

[0066] The third step: adding AlTi10 alloy, AlSr10 alloy, AlLa5 alloy and AlCe5 alloy to the aluminum alloy liquid for refinement and modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com