Al-Cu alloy wire for additive manufacturing and preparation method and application of Al-Cu alloy wire

An additive manufacturing and alloy wire technology, applied in the field of additive manufacturing, can solve the problems of easy occurrence of micro-cracks and low mechanical properties, and achieve the effect of high strength and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

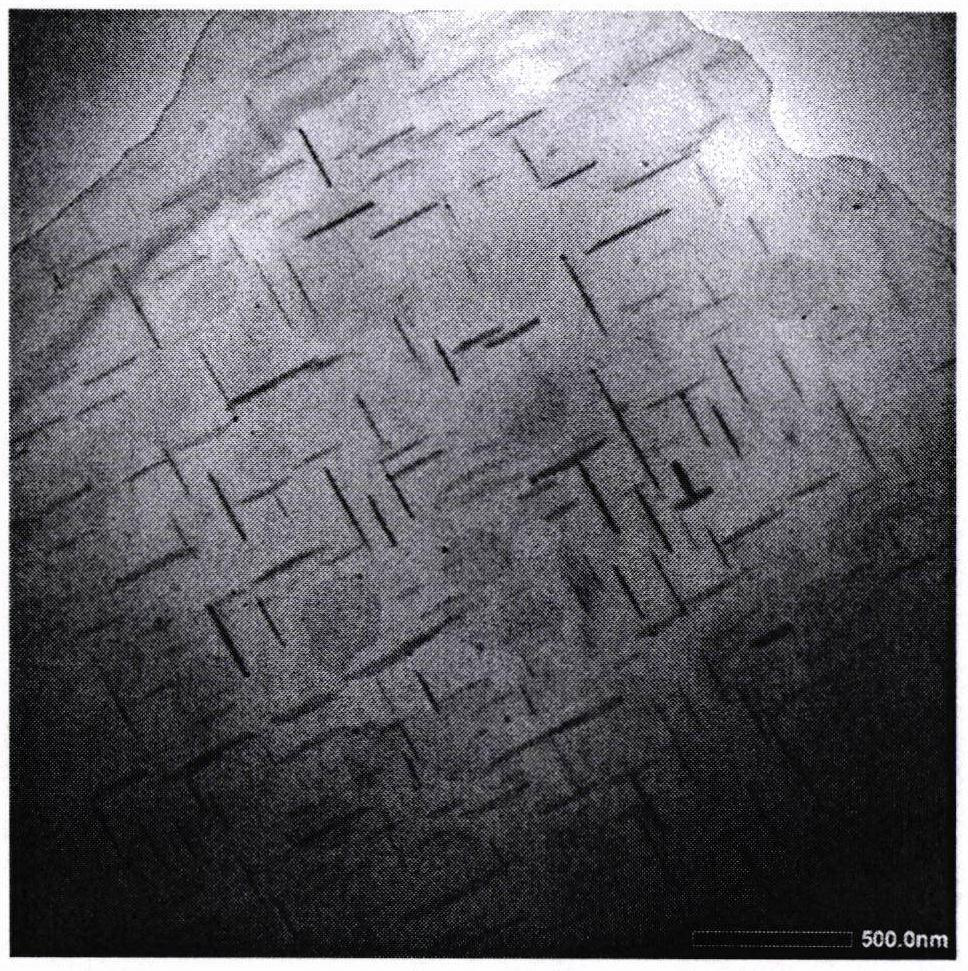

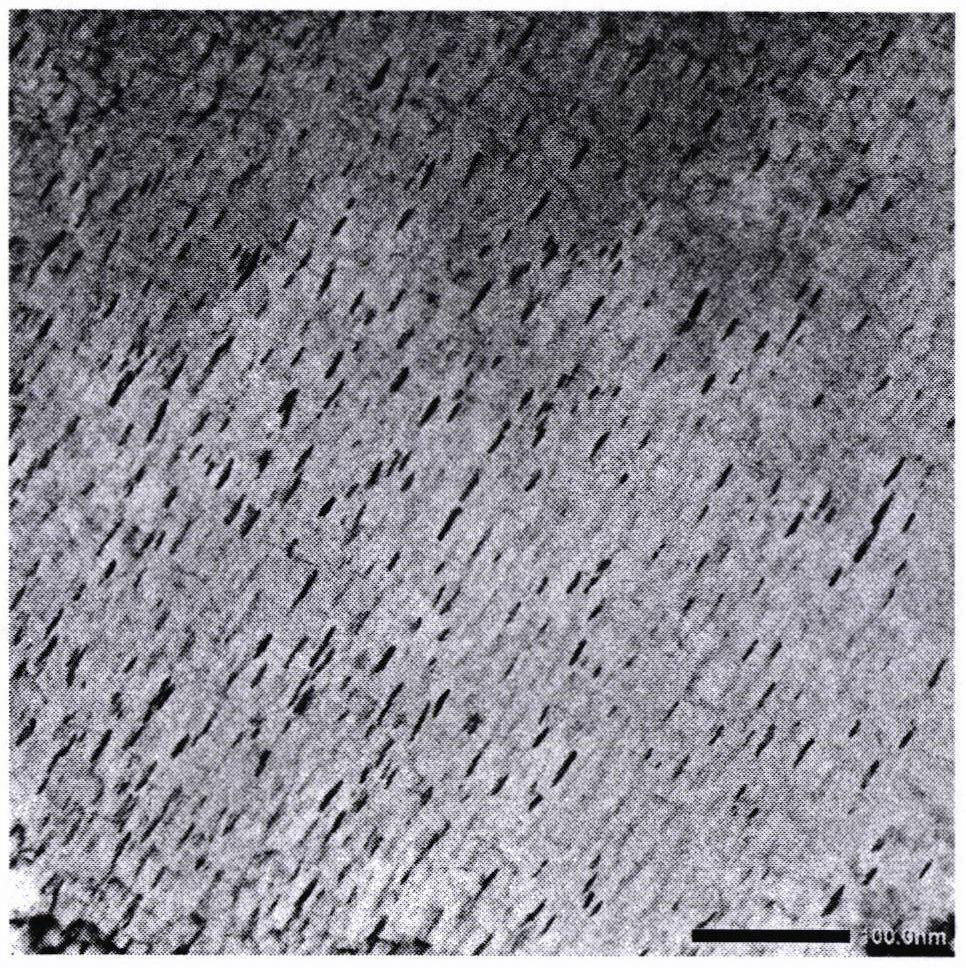

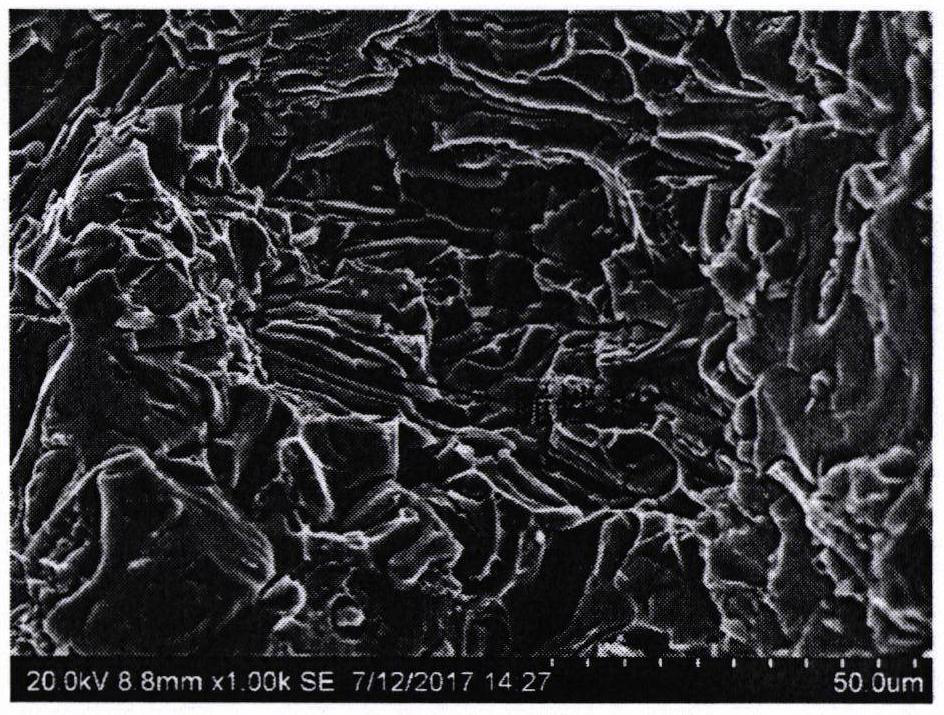

Image

Examples

Embodiment 1

[0044] In terms of mass percentage, its chemical composition is: Cu: 6.0%, Fe: 0.13%, Si: 0.04%, Mn: 0.3%, Mg: 0.02%, Zn: 0.01%, Ti: 0.1%, Zr: 0.15%, V: 0.1%, Cd: 0.1%, Sc: 0.15%.

[0045] A method for preparing an Al-Cu alloy for additive manufacturing, the specific steps comprising:

[0046] 1) Select high-purity aluminum ingots and intermediate alloys such as Cu, Mn, V, and Zr for batching according to the composition ratio. When batching, Fe / Si is controlled at 3.25, and the total content of Mn, Ti, and V is controlled at 0.5%.

[0047] 2) Vacuum melting, and argon protection, argon chlorine gas and flux compound refining,

[0048] The specific steps of refining include:

[0049] The first step: add high-purity aluminum ingots, AlCu50, AlMn10, AlV3 and AlZr3 and other intermediate alloys in sequence, heat and melt, stir, and control the melt temperature at 760-780 °C;

[0050] Step 2: Add Cd, Sn or In and Sc, heat to melt, stir, and control the melt temperature at 740-7...

Embodiment 2

[0061] In terms of mass percentage, its chemical composition is: Cu: 6.1%, Fe: 0.12%, Si: 0.04%, Mn: 0.31%, Mg: 0.02%, Zn: 0.01%, Ti: 0.11%, Zr: 0.12%, V: 0.1%, Sc: 0.15%.

[0062] A method for preparing an Al-Cu alloy for additive manufacturing, the specific steps comprising:

[0063] 1) Select high-purity aluminum ingots and intermediate alloys such as Cu, Mn, V, and Zr for batching according to the composition ratio. When batching, Fe / Si is controlled at 3.0, and the total content of Mn, Ti, and V is controlled at 0.52%.

[0064] 2) Vacuum melting, combined refining with argon protection, argon chlorine gas and flux. The specific steps include: first step: adding high-purity aluminum ingots, intermediate alloys such as AlCu50, AlMn10, AlV3 and AlZr3 in sequence, heating and melting, stirring, and controlling the melt temperature at 760-780°C. Step 2: Add Cd, Sn or In and Sc, heat to melt, stir, and control the melt temperature at 740-760°C. The third step: Ti addition, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com