Heat-resistant casting aluminum-zinc alloy and preparation method thereof

A technology for casting aluminum and zinc alloys, applied in the field of aluminum-zinc alloys, can solve the problems of low working temperature and strength, inability to meet the service temperature requirements of special engines and engine soundproof covers and application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

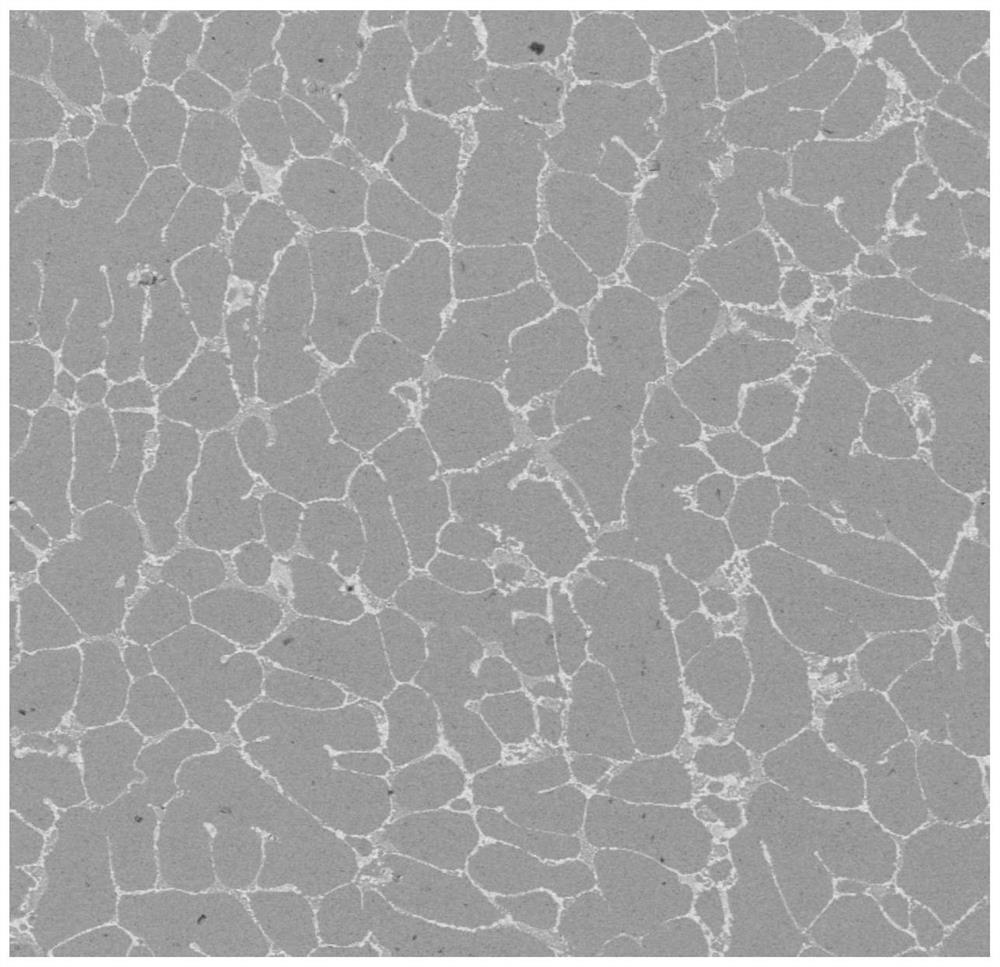

Image

Examples

preparation example Construction

[0030] A kind of preparation method of heat-resistant cast aluminum-zinc alloy of the present invention comprises the following steps:

[0031] 1) First, heat the furnace to increase the temperature of the furnace to 200-280°C and keep it warm for 20-35 minutes. Then, put in the raw materials containing Al, Zn, Si, and Cu Continue heating with the raw material containing Ca element to raise the temperature of the furnace to 720-730°C, keep it warm for 1-2h, and stir for 20-30min to obtain an aluminum alloy melt;

[0032] 2) Lower the temperature to lower the furnace temperature to 700-710°C, add raw materials containing Ba element, stir for 10-15 minutes, add refining agent, the amount of refining agent added is 0.4-0.6% of the total weight of the aluminum alloy melt, and stir for 5 -10min;

[0033] 3) Keep the furnace temperature at 700-710°C, add raw materials containing Mg, stir for 3-5 minutes, use inert gas to rotate and spray for 10-15 minutes, let stand for 5-8 minutes...

Embodiment 1

[0042] A kind of preparation method of heat-resistant cast aluminum-zinc alloy of the present invention comprises the following steps:

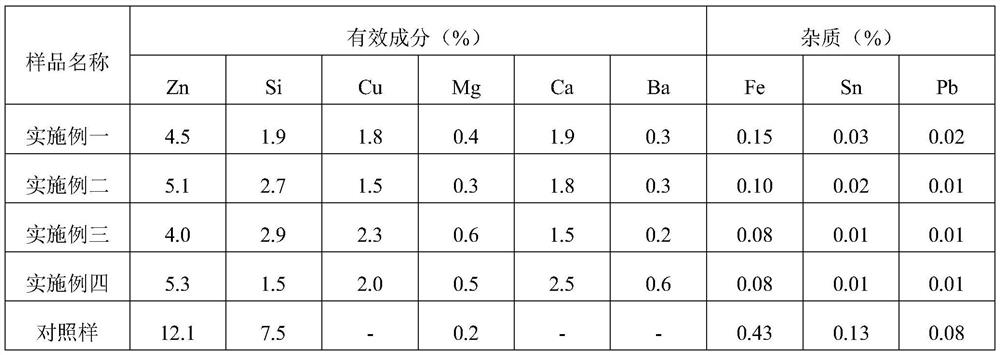

[0043] 1) Weigh raw materials according to the obtained heat-resistant cast aluminum-zinc alloy containing the following elements in weight percentage, Zn4.5%, Si1.9%, Cu1.8%, Mg0.4%, Ca1.9%, Ba0.3%, impurities less than or Equal to 0.2% and the balance is Al;

[0044] Among them, Al, Zn, Ca and Mg are pure metals, pure metal aluminum is Al99.993, and the element content requirements meet the requirements of GB / T8644-2000; pure metal zinc is Zn99.95, and the element content requirements meet GB / T 470-2008 Requirements; pure metal calcium is Ca99.99, and the element content requirements meet the requirements of GB / T 4864-2008; pure metal magnesium is Mg99.95, and the element content requirements meet the requirements of GB / T 3499-1995; Si adopts AlSi12 master alloy, and the element content requirements It is required to meet the requirements ...

Embodiment 2

[0049] A kind of preparation method of heat-resistant cast aluminum-zinc alloy of the present invention comprises the following steps:

[0050] 1) Weigh raw materials according to the obtained heat-resistant cast aluminum-zinc alloy containing the following elements in weight percentage, Zn5.1%, Si 2.7%, Cu 1.5%, Mg 0.3%, Ca 1.8%, Ba 0.3%, impurities less than or Equal to 0.2% and the balance is Al;

[0051] Among them, Al, Zn, Ca and Mg are pure metals, pure metal aluminum is Al99.993, and the element content requirements meet the requirements of GB / T8644-2000; pure metal zinc is Zn99.95, and the element content requirements meet GB / T 470-2008 Requirements; pure metal calcium is Ca99.99, and the element content requirements meet the requirements of GB / T 4864-2008; pure metal magnesium is Mg99.95, and the element content requirements meet the requirements of GB / T 3499-1995; Si adopts AlSi12 master alloy, and the element content requirements It is required to meet the requirem...

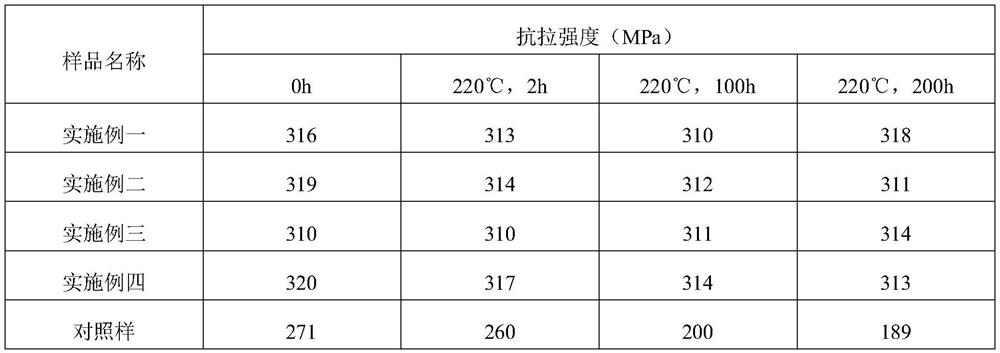

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com