A method for separating iron element impurities by pulse current in recycled aluminum melt

A pulse current and iron impurity technology is applied in the field of removing iron impurity elements in regenerated aluminum melt, which can solve the problems of aluminum alloy melt pollution, long time period, complicated operation, etc., and achieves the effect of continuous processing, easy implementation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

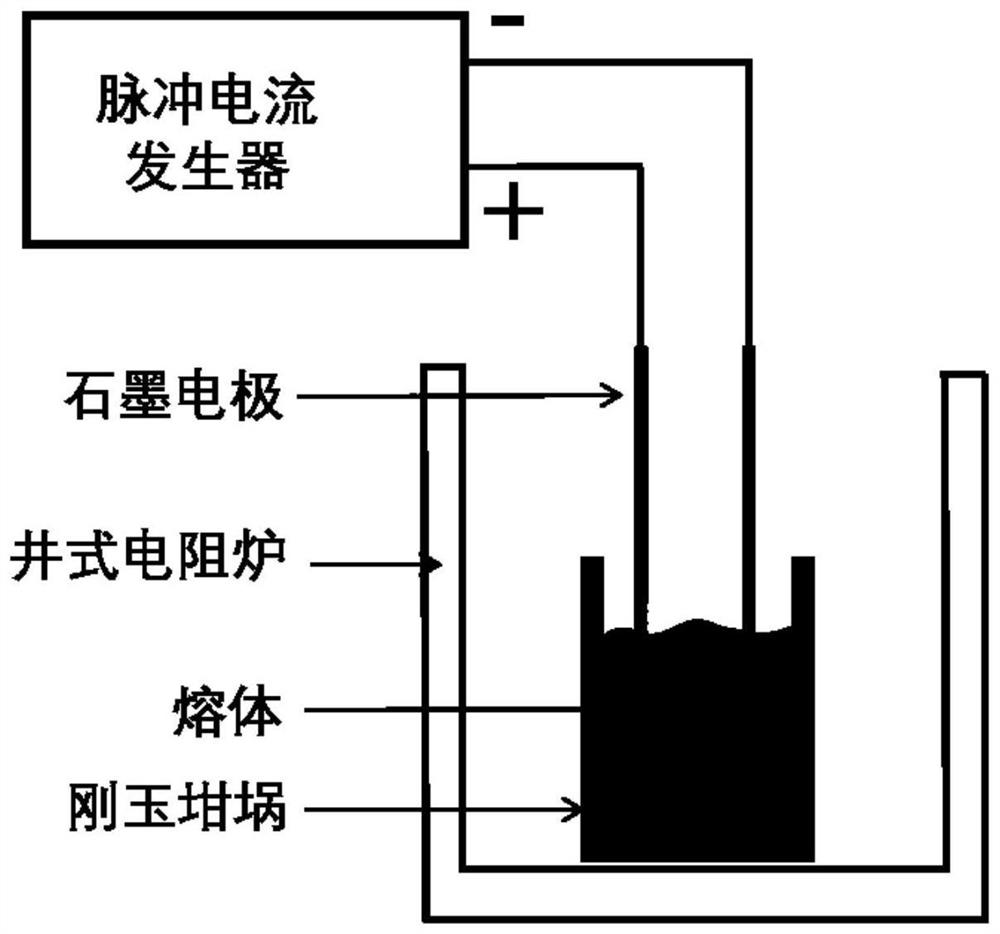

[0024] In this embodiment, pulse current treatment is performed on the Al-2.2% Fe melt in the crucible. Specific steps are as follows:

[0025] Step 1: Put the configured Al-2.2% Fe alloy material into a crucible and heat it in a resistance furnace to 1200°C for 60 minutes. To ensure that the acicular iron-rich phase in the master alloy Al-20%Fe is completely dissolved and the melt is homogenized. The size of the crucible is Φ50mm (inner diameter)×60mm.

[0026] Step 2: Determine the pulse processing parameters. Set the parameter range of the pulse current, and determine the pulse current parameters as frequency 31kHz, voltage 8V, pulse current density 9.8A / cm 2 , The action time is 70min.

[0027] The third step: pulse current treatment. When the Al-2.2% Fe melt is cooled down to 900°C with the furnace, two electrodes are inserted into the melt in parallel, and the pulse current treatment is started. After holding at this temperature for 10 minutes, cut off the heating ...

Embodiment 2

[0032] In this embodiment, pulse current treatment is performed on the Al-2.2% Fe melt in the crucible. Specific steps are as follows:

[0033] Step 1: Put the configured Al-2.2% Fe alloy material into a crucible and heat it in a resistance furnace to 1200°C for 60 minutes. To ensure that the acicular iron-rich phase in the master alloy Al-20%Fe is completely dissolved and the melt is homogenized. The size of the crucible is Φ50mm (inner diameter)×60mm.

[0034] The second step: determine the pulse current processing parameters. Set the parameter range of the pulse current, and determine the pulse current parameters as frequency 10kHz, voltage 12V, pulse current density 24.5A / cm 2 , The action time is 70min.

[0035] The third step: pulse current treatment. When the Al-2.2% Fe melt is cooled down to 900°C with the furnace, two electrodes are inserted into the melt in parallel, and the pulse current treatment is started. After holding at this temperature for 10 minutes, c...

Embodiment 3

[0040] In this embodiment, pulse current treatment is performed on the Al-2.2% Fe melt in the crucible. Specific steps are as follows:

[0041] Step 1: Put the configured Al-2.2% Fe alloy material into a crucible and place it in a resistance furnace to heat to 1200°C and keep it warm for 60min. To ensure that the acicular iron-rich phase in the master alloy Al-20%Fe is completely dissolved and the melt is homogenized. The size of the crucible is Φ70mm (inner diameter)×70mm.

[0042] The second step: determine the pulse current processing parameters. Set the parameter range of the pulse current, and determine the pulse current parameters as frequency 200Hz, voltage 24V, pulse current density 49A / cm 2 , the action time is 10min.

[0043] The third step: pulse current treatment. When the Al-2.2% Fe melt is cooled down to 750°C with the furnace, two electrodes are inserted into the melt in parallel, and the pulse current treatment is started. After holding at this temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com