155ksi steel grade high strength-toughness casing steel, casing pipe and preparation method of casing steel and casing pipe

A 1.155ksi, high-strength and toughness technology, used in casing and its preparation, 155ksi steel grade high-strength toughness casing steel field, can solve the problem of unstable toughness, and achieve the effect of good matching of strength and toughness and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned 155ksi steel grade high-strength toughness casing steel comprises the following steps:

[0035] a. Steelmaking: use molten iron with low five harmful elements, pig iron and pipe heads as raw materials, and smelt them on an electric arc furnace to obtain primary molten steel;

[0036] b. LF refining and VD vacuum degassing treatment: LF refining is performed on the initial molten steel, and calcium treatment is carried out after refining; after calcium treatment, VD vacuum degassing treatment is carried out, and the degassing treatment is performed at a vacuum degree ≤ 67Pa for 15 minutes. Degassing treatment for at least 5 minutes under vacuum degree ≤ 200Pa, then calcium treatment, static blowing treatment after calcium treatment, static blowing time ≥ 15 minutes, tapping, tapping temperature 1570 ~ 1585 ℃;

[0037] c. Casting: cast the steel processed in step b into a continuous casting round billet.

[0038] In the above ste...

Embodiment 1

[0052] ①Steelmaking

[0053] Using molten iron, pig iron and pipe heads with low five harmful elements as raw materials, it is guaranteed that the endpoint As≤0.020%, Sn≤0.010%; and As+Sn+Pb+Sb+Bi≤0.025%.

[0054] Strengthen deoxidation during the tapping process, the amount of deoxidizer added: CaBaAlSi 1.5-2.5kg / t, Al block 2-3kg / t; add lime 2.5-4.5kg / t in the ladle before tapping.

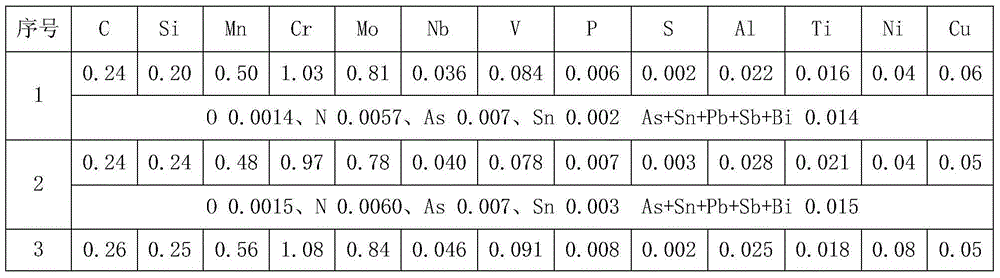

[0055] LF refining and smelting molten steel, adjust the composition to include: C 0.23-0.27%, Si 0.20-0.35%, Mn 0.45-0.60%, Cr 0.95-1.10%, Mo 0.75-0.85%, Nb 0.03-0.05% by mass percentage , V 0.07~0.12%, Al0.015~0.045%, Cu≤0.20%, Ni≤0.20%, Ti≤0.04%, P≤0.010%, S≤0.003%, O≤0.0020%, N≤0.0080%; As ≤0.020%, Sn≤0.010%, and As+Sn+Pb+Sb+Bi≤0.025%, the rest is qualified molten steel for Fe, residual elements and impurities.

[0056] Ensure that the white slag time is ≥ 20 minutes, so that the inclusions in the steel can be fully floated; at the same time, the secondary calcium treatment process is adop...

PUM

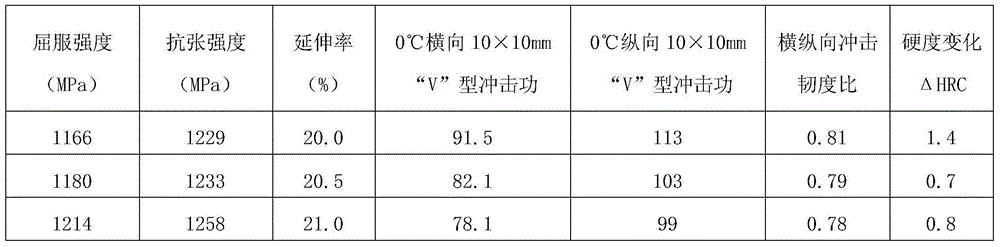

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com