Aluminum-silicon based aluminum section and preparation technology thereof

An aluminum-silicon-based aluminum profile and a preparation process technology are applied in the field of aluminum profiles and their preparation technology, which can solve problems such as high price and achieve the effects of reducing power consumption, high hardness and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation process of the aforementioned aluminum-silicon-based aluminum profile includes the following steps:

[0037] The first step: Put the aluminum-silicon alloy into a graphite crucible, heat it to 760°C with a resistance wire to melt, and keep it for 30 minutes to form a melt.

[0038] The second step: add magnesium, silicon and reinforcing elements to the melt prepared in the first step so that the weight percentage of silicon is between 5.0% and 14.0%, and the weight percentage of magnesium is between 0.2% and 0.7%. The weight percentage of the reinforcing element is between 0.1% and 6.55%. After holding for 30 minutes, the temperature is lowered to 730℃ to form a melt.

[0039] The third step: adding hexachloroethane to the melt prepared in the second step for refining, and after standing for 10 minutes, a melt is formed.

[0040] The fourth step: add strontium to the melt prepared in the third step to change the quality. The weight percentage of strontium is bet...

Embodiment 1

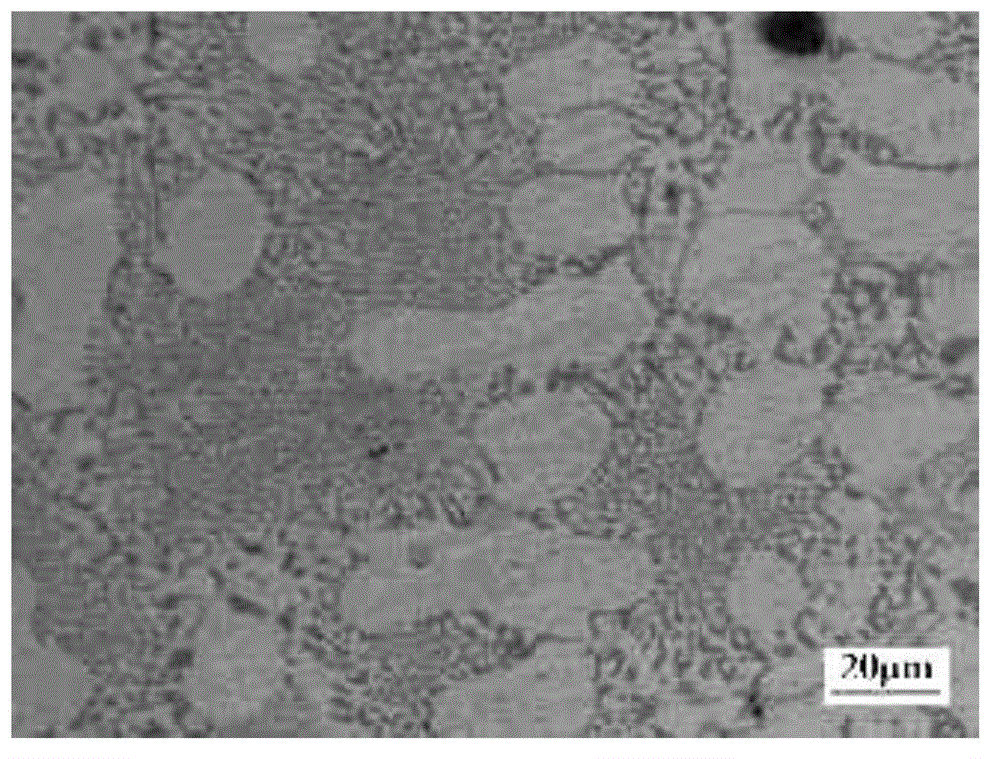

[0046] The raw material is ZL102 (ZL102 stands for cast aluminum 102, the silicon content is 10.0%-13.0%, the balance is aluminum). Put ZL102 into a graphite crucible, use resistance wire to heat to 760℃ to melt, keep it for 30 minutes; then add 0.4wt% pure magnesium to ZL102, keep it for 30 minutes, then cool to 730℃, add hexachloroethane for refining After standing for 10 minutes, add strontium Sr element, after holding for 30 minutes, a melt is formed; after holding for 5 minutes, the obtained melt is cast into a cast iron mold preheated to 200 degrees Celsius, and naturally cooled to form an ingot. After homogenization annealing, hot extrusion and hot rolling deformation are carried out at a temperature of 400℃-550℃, and then solution treatment is carried out at a temperature of 500℃-550℃. The solution treatment time is 3-6 hours, and then The aging treatment is carried out at a temperature between 150°C and 250°C, and the aging treatment time is 3-20 hours, so as to obtain...

Embodiment 2

[0055] The preparation process is the same as in Example 1, but the difference: On the one hand, the raw material used in Example 2 is ZL101 (ZL101 stands for cast aluminum 101, with a silicon content of 6.5%-7.5%, a magnesium content of 0.25%-0.45%, and the balance Is aluminum), on the other hand: adding 0.2wt% pure magnesium to ZL101 to compensate for the burning loss of magnesium, instead of 0.4wt% pure magnesium in Example 1.

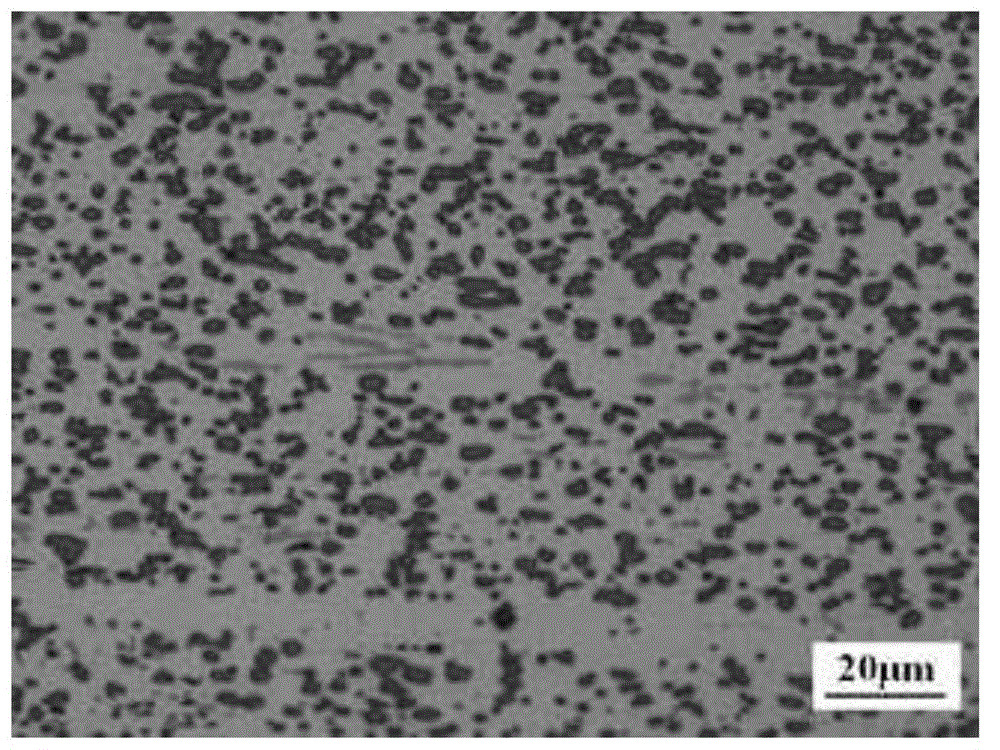

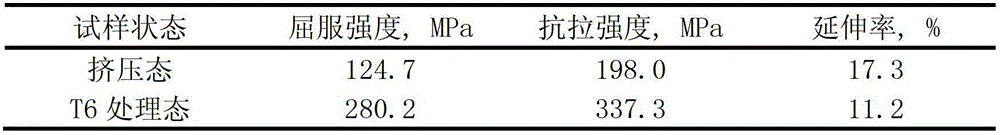

[0056] The chemical composition of aluminum-silicon-based aluminum profiles was measured by ICP direct-reading spectrometer. The results are as follows: Si: 6.99%, Mg: 0.560%, Fe: 0.124%, Sr: 0.011%, Ti: 0.131%, Pb: <0.0005, Sn: <0.001, Ca: 0.00070, the balance is Al. The quenched extruded samples and the T6 processed samples were processed into plate-like tensile samples by wire cutting, and three parallel samples were taken from each state. According to the national standard "GBT228-2002 Metallic Material Room Temperature Tensile Test Method", on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com