Process for producing cation exchangers

a technology of cation exchangers and cation exchangers, which is applied in chemical/physical processes, water/sewage treatment by ion exchange, nuclear engineering, etc., can solve the problems of unfavorable cation exchanger function, unsatisfactory stability of cation exchangers, and damage to bead polymers, so as to reduce the throughput of liquid to be purified, the effect of rapid exchange kinetics, high mechanical and osmotic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

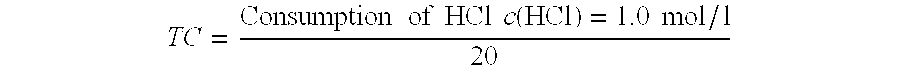

Method used

Image

Examples

example 1

Preparation of a Monodisperse Seed Bead Polymer Based on styrene, divinylbenzene and ethylstyrene

[0081]A 4 l glass reactor was initially charged with 1020 g of demineralized water, and a solution of 3.2 g of gelatin, 4.8 g of disodium hydrogenphosphate dodecahydrate and 0.24 g of resorcinol in 86 g of demineralized water was added and mixed. The temperature of the mixture was adjusted to 25° C. With stirring, 1182 g of microencapsulated monomer droplets which had been obtained by jetting and had a narrow particle size distribution, containing 4.5% by weight of divinylbenzene, 1.12% by weight of ethylstyrene, 0.36% by weight of tert-butyl peroxy-2-ethylhexanoate and 94.02% by weight of styrene, were added with stirring, the microcapsules having consisted of a formaldehyde-hardened complex coacervate of gelatin and a copolymer of acrylamide and acrylic acid, and 1182 g of aqueous phase with a pH of 12 were added.

[0082]The mixture was polymerized to completion with stirring by increasi...

example 2 (

Inventive)

2a) Preparation of a Bead Polymer with diethylene glycol divinyl ether

[0094]In a 4 l stirred reactor with gate stirrer, condenser, temperature sensor and thermostat and temperature recorder, an aqueous initial charge composed of 1443 g of deionized water and 5.88 g of disodium hydrogenphosphate dodecahydrate was obtained. To this initial charge were added, with stirring at 200 rpm, 864.9 g of seed polymer prepared as in example 1.

[0095]Within 30 min, a mixture of 625.7 g of styrene, 109.5 g of divinylbenzene (81.4%) and 5.88 g of dibenzoyl peroxide was added. To remove atmospheric oxygen, the mixture was then sparged with nitrogen for 15 minutes. Subsequently, the reactor contents were brought to 30° C. within 30 minutes and kept at this temperature for 30 minutes. A solution of 3.2 g of methylhydroxyethylcellulose dissolved in 157 g of water was then added, and the mixture was stirred at 30° C. for another 1 hour. The mixture was heated to 62° C. for 16 hours. Then 30 g o...

example 3 (

Inventive)

3a) Preparation of Bead Polymers with diethylene glycol divinyl ether

[0098]In a 4 l stirred reactor with gate stirrer, condenser, temperature sensor and thermostat and temperature recorder, an aqueous initial charge composed of 1443 g of deionized water, 4.85 g of boric acid and 2.72 g of 50% by weight sodium hydroxide solution was obtained. To this initial charge were added, with stirring at 200 rpm, 864.9 g of seed polymer prepared as in example 1.

[0099]Within 30 min, a mixture of S g of styrene (see table), 109.5 g of divinylbenzene (81.3%), X g of diethylene glycol divinyl ether (DEGDVE, see table) and 2.35 g of tert-butyl peroxy-2-ethylhexanoate was added. To remove atmospheric oxygen, the mixture was then sparged with nitrogen for 15 minutes. Subsequently, the reactor contents were brought to 30° C. within 30 minutes and kept at this temperature for 30 minutes. Then a solution of 3.2 g of methylhydroxyethylcellulose dissolved in 157 g of water was added and the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com