Patents

Literature

33results about How to "Low chroma value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

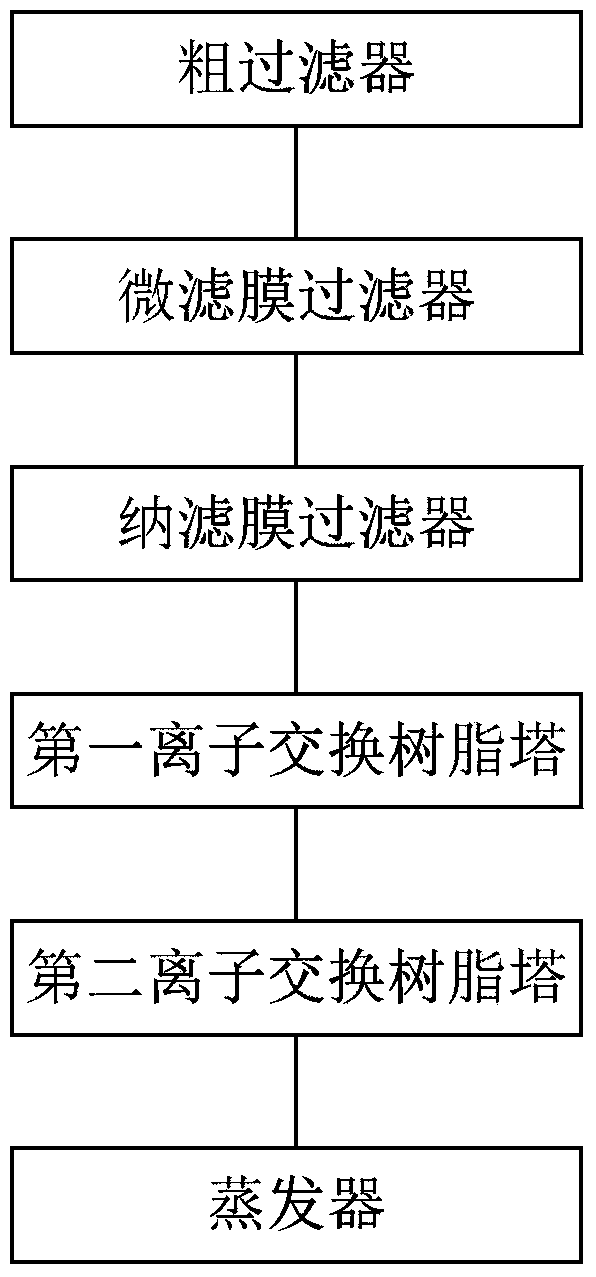

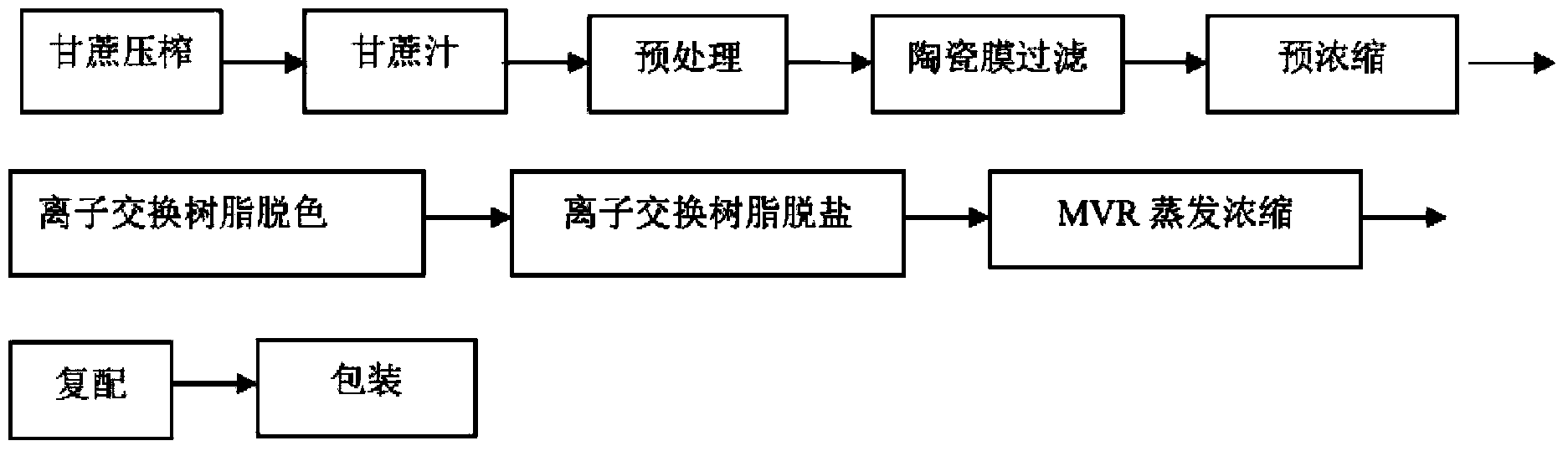

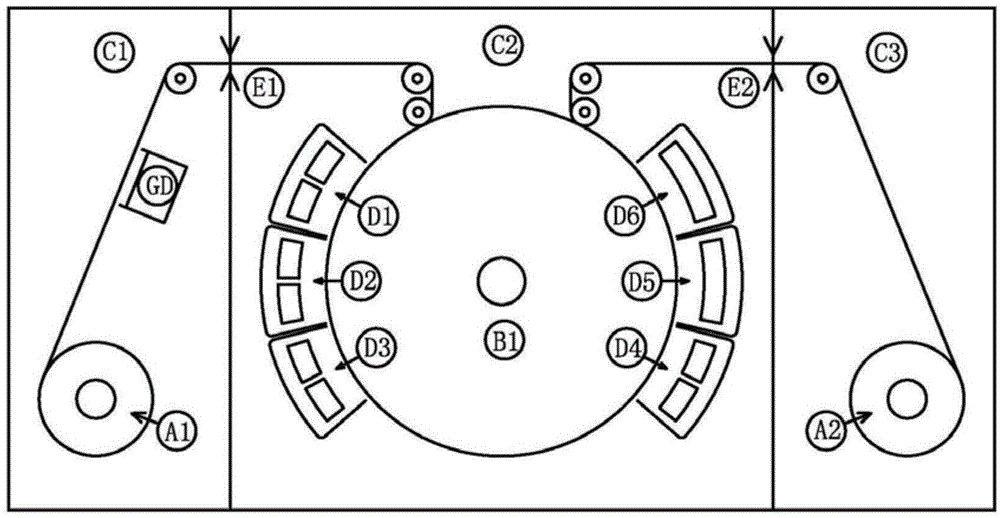

Production technique and device of directly edible edible syrup

ActiveCN103710469ALow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansSucroseMicrofiltration membrane

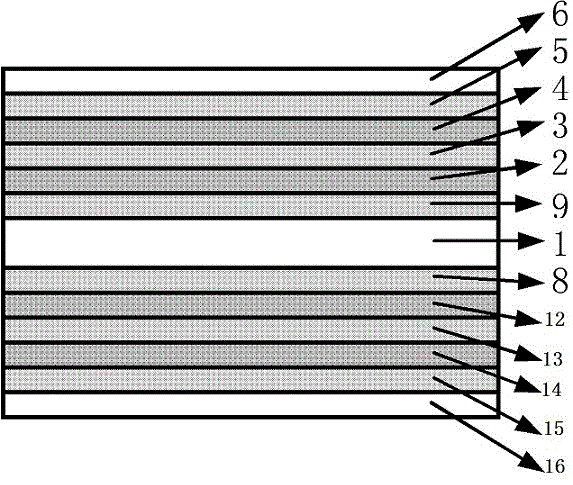

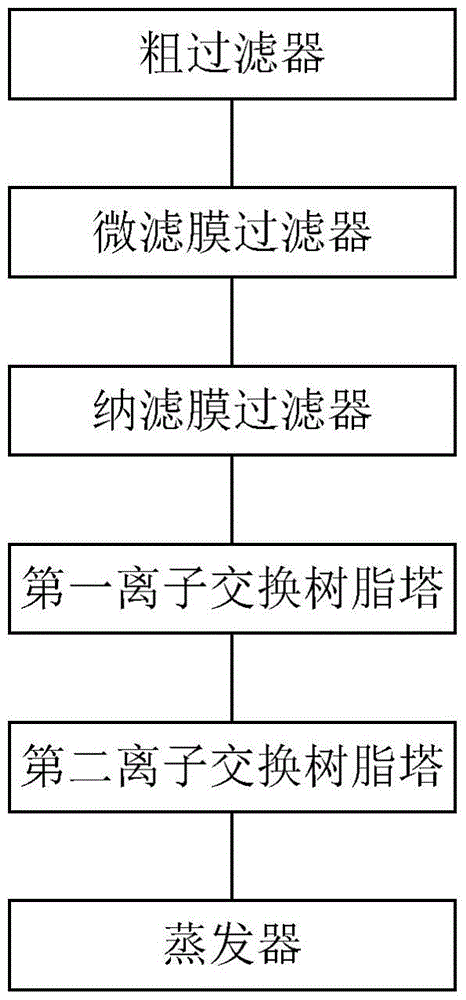

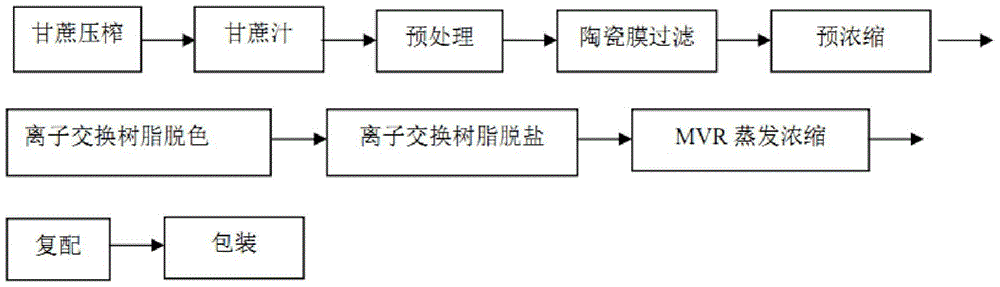

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

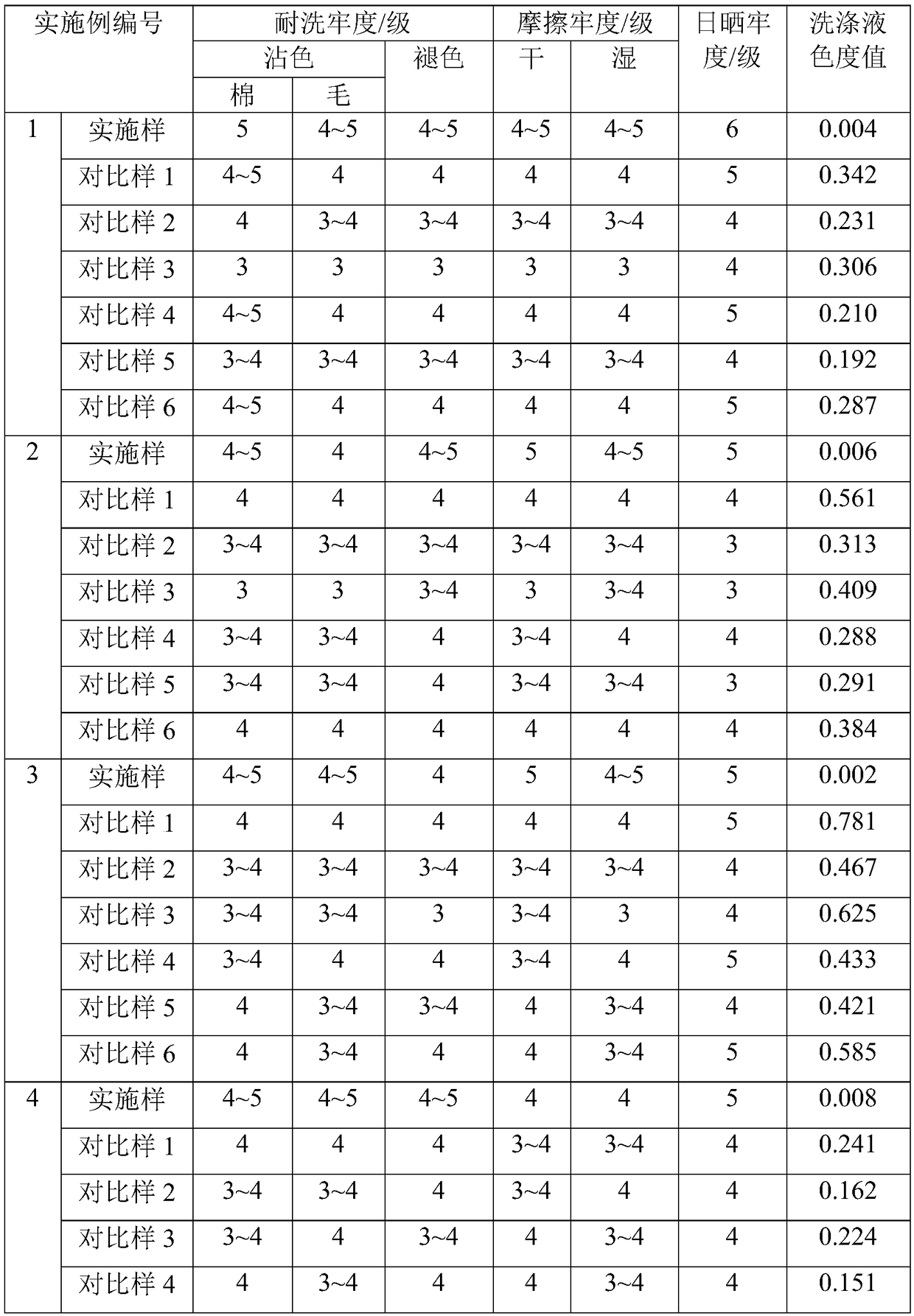

Method for performing complete cotton knitted fabric dyeing post treatment using immobilization laccase

InactiveCN101302716AIncrease temperatureImprove stabilityBiochemical fibre treatmentOn/in organic carrierEcological environmentPolyethylene glycol

The invention discloses a post processing method for the dyeing of all-cotton knitted fabrics that applies an immobilized laccase, belongs to the technical field of the application of the dyeing and finishing treatment of the knitted fabrics in the printing and dyeing industry, and aims at solving the technical problems that traditional post processing of the knitted fabric dyeing has high soaping temperature, large water consumption and residual washing water with deep chromaticity and achieving the goal for optimizing the post processing effect of the dyeing. The post processing method of the invention adopts calcium alginate and gelatinum as carriers so as to implement the imbedding of the laccase, improves the immobilization efficiency of the laccase in the carriers through glutaraldehyde crosslinking, improves the heat and pH stability of the laccase in the carriers by adding polyethyleneglycol, and realizes the circulation of the immobilized laccase in the post enzyme-washing treatment of the dyeing of the all-cotton knitted fabrics by adding carmowax to improve the thermal stability and the pH stability of the laccase in the carriers. By adopting the post processing method of the invention, the enzyme-washing technique with the immobilized laccase can replace traditional chemical soaping techniques, can not only effectively remove superficial loose color of the dyed all-cotton knitted fabrics and improve the wet processing fastness of the fabrics, but also effectively lower the chromaticity of the post processing residual liquid and release the burden of the sewage treatment of the printing and dyeing, and the post processing method of the invention is favorable for protecting ecological environment.

Owner:JIANGNAN UNIV

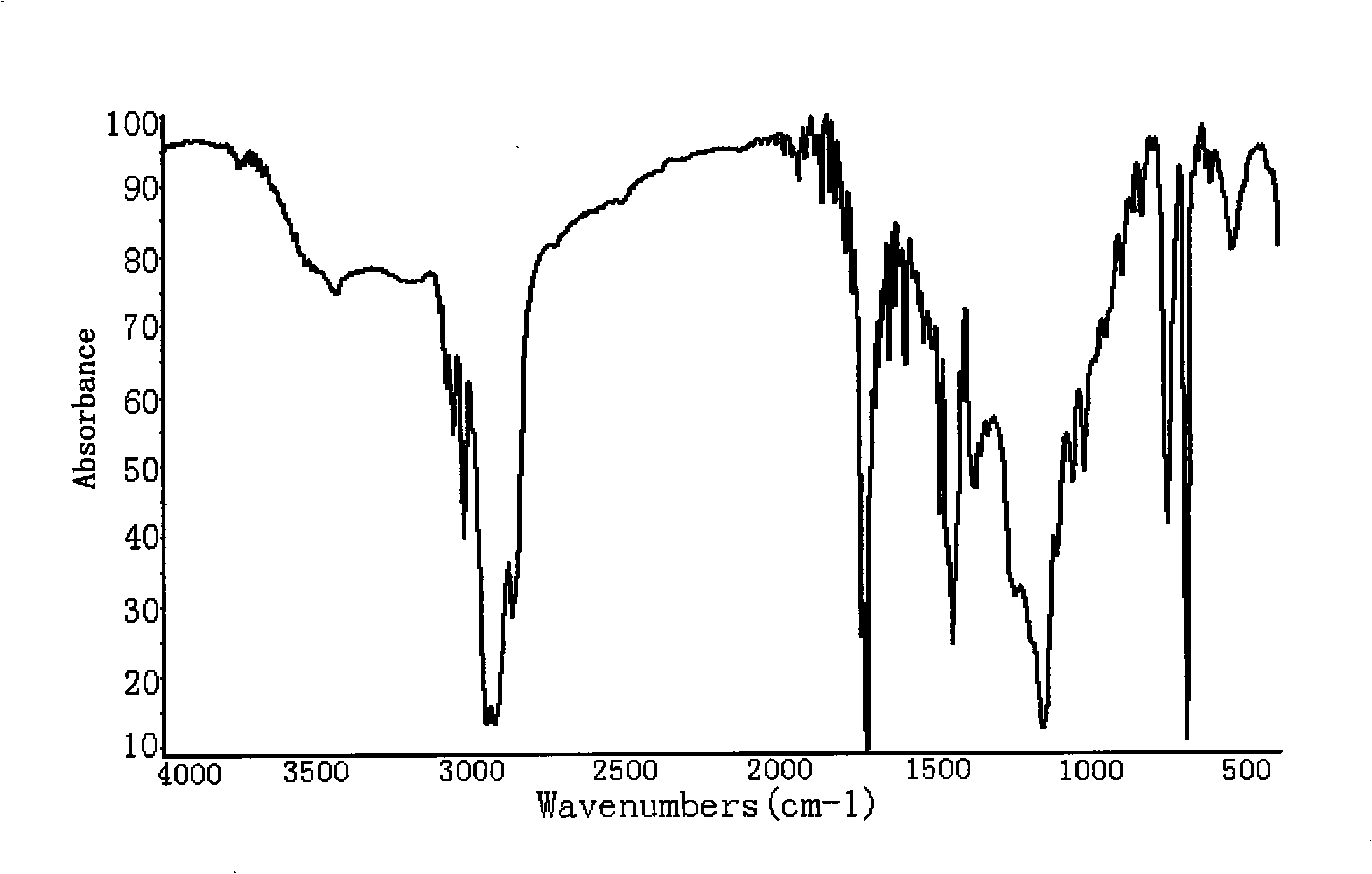

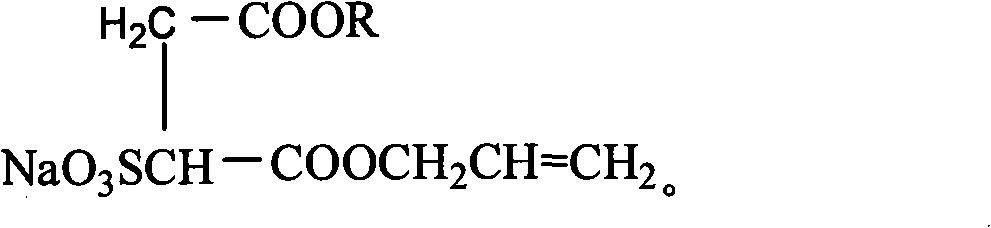

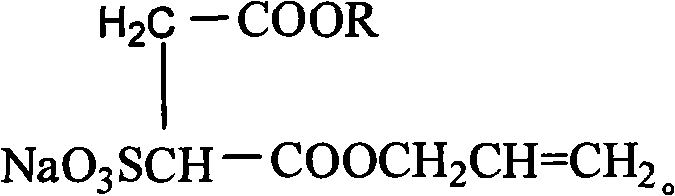

Filming flow type polyacrylacid ester soap-free emulsion, synthetic process and use thereof in printing ink

The invention provides a soap-free acrylic acid latex, and a preparation method thereof and application in water-based ink. On one hand, a polymeric surfactant can be used to replace the prior surfactant during the reaction process; and after the latex is dried and forms a film, compounds with low molecular weight are reduced greatly and the water resistance of the film is effectively improved. On the other hand, protective glue is introduced into the reaction process to change the rheological property of the latex, and the rheological property of the latex is close to that of Newtonian liquid; simultaneously, the protective glue can also further improve the mechanical stability of the latex and make the latex more suitable for the water-based ink.

Owner:广东天龙油墨有限公司

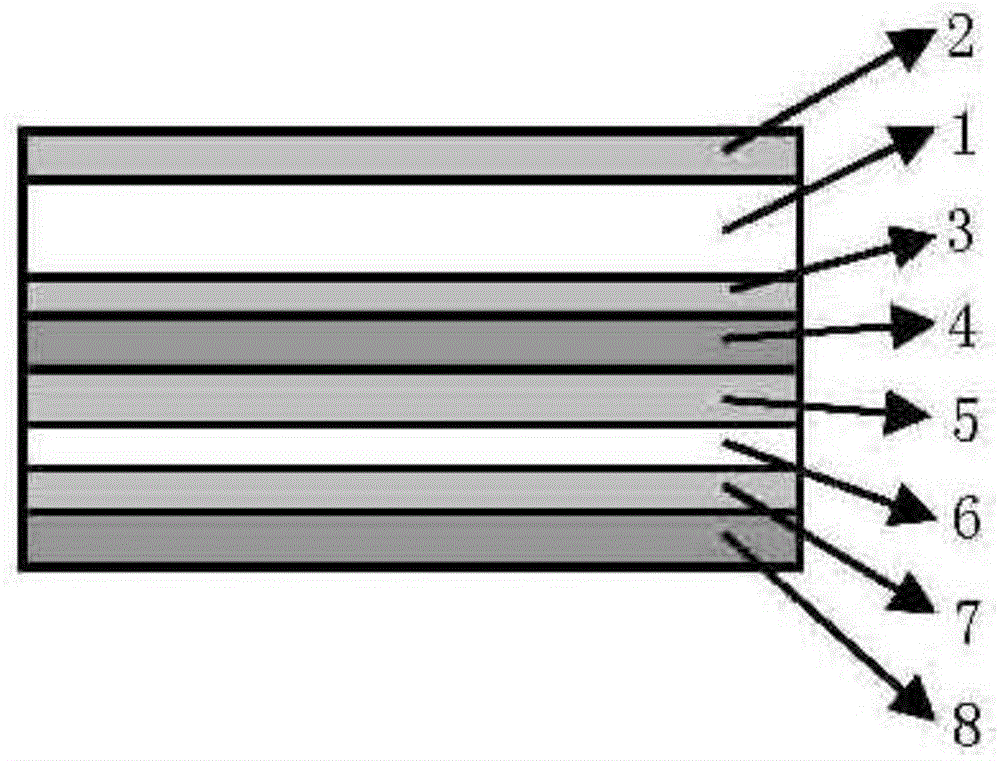

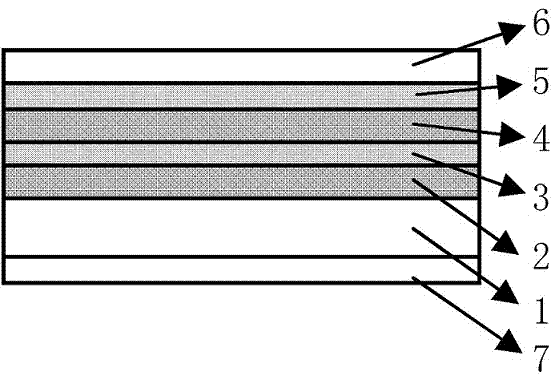

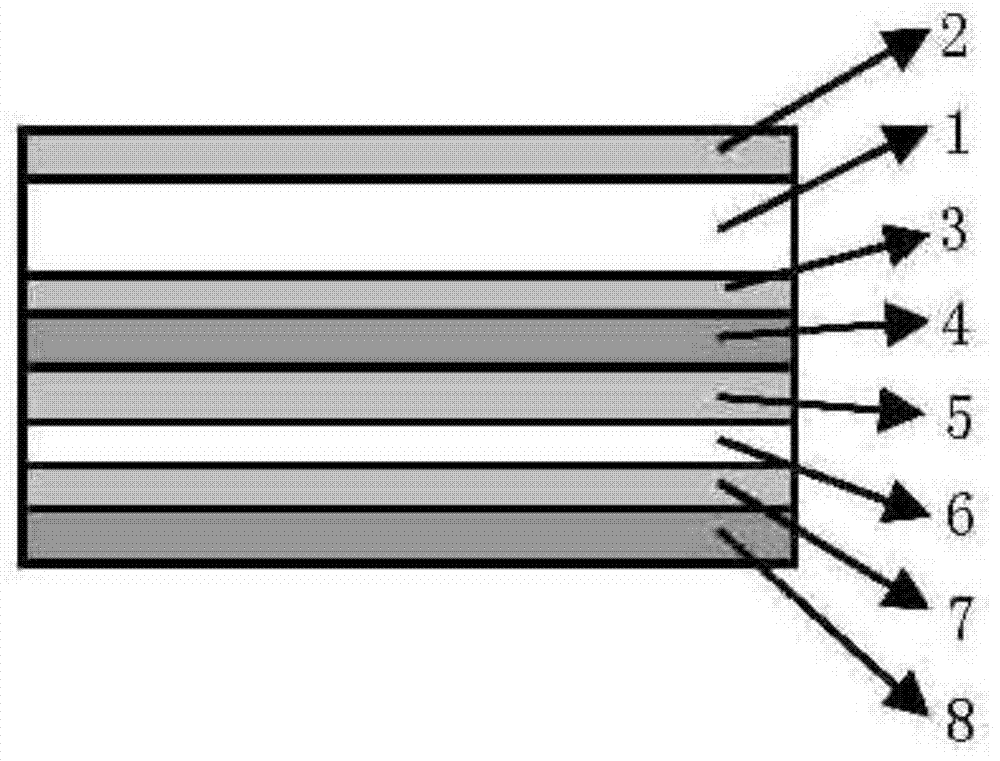

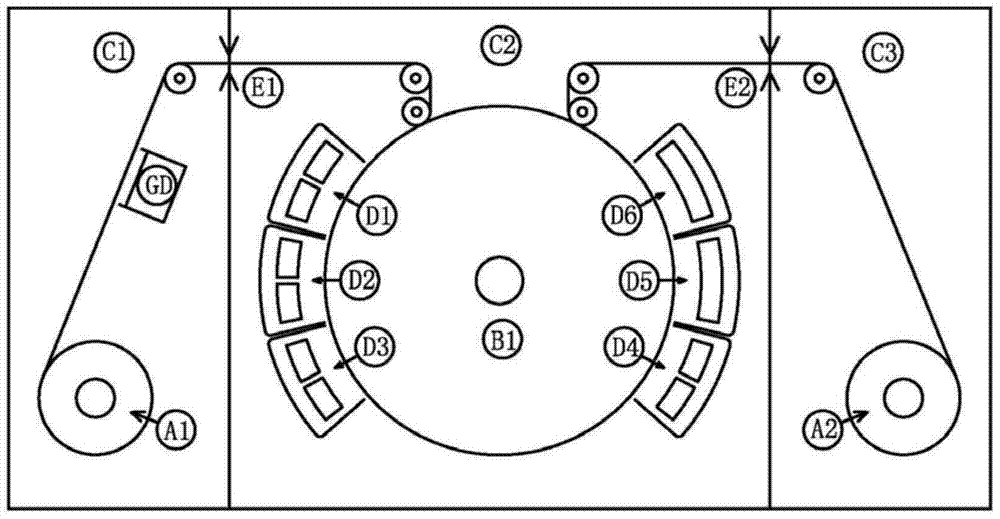

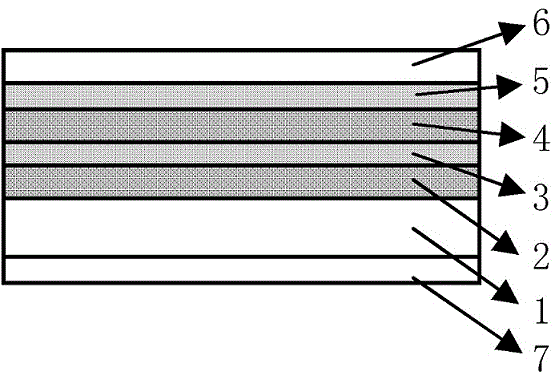

Energy-saving flexible transparent conducting film and preparation method thereof

ActiveCN104651791AHigh light transmittanceLow resistivityVacuum evaporation coatingSputtering coatingOptical transmittanceTransparent conducting film

The invention provides a preparation method of an energy-saving flexible transparent conducting film. After the film is formed, no high-temperature annealing is needed, thereby lowering the energy consumption; and the film crystallization degree is up to 80%, and thus, the method is suitable for large-scale industrialized production. The method uses a plurality of magnetron sputtering devices in one vacuum coating cavity, wherein each magnetron sputtering device comprises a sputtering cavity which uses inert gas as working gas and oxygen as reactant gas, and a target positioned in the sputtering cavity; a continuously moving flexible transparent substrate sequentially passes through the sputtering cavities of the target drones, wherein the temperature of the flexible transparent substrate is less than 80 DEG C; and by controlling the flow rates of the oxygen and inert gas introduced into the sputtering cavities, the target or target oxide is deposited on the flexible transparent substrate at one time. The invention also provides an energy-saving flexible transparent conducting film with high light transmittance, low resistivity and low chromatic value, which comprises a flexible transparent substrate, and a SiO2 layer, a Nb2O5 layer, a Nb2Ox layer (x=4.5-4.98), a SiO2 layer, a silver layer or copper layer and a semiconductor oxide layer which are sequentially deposited on the flexible transparent substrate.

Owner:高邮市汇金新材料科技有限公司

Printing-dyeing wastewater purifier and utilization method of printing-dyeing wastewater purifier

ActiveCN105502529ALow chroma valueLow costWater/sewage treatment by ion-exchangeWaste water treatment from textile industryDyeing wastewaterSodium sulfate

The invention belongs to the field of wastewater treatment, and relates to a printing-dyeing wastewater purifier and a utilization method of the printing-dyeing wastewater purifier. The printing-dyeing wastewater purifier is characterized by being prepared from the following raw materials in terms of parts by weight: 15-25 parts of polyacrylamide, 10-15 parts of bamboo charcoal, 15-30 parts of sodium carbonate, 15-25 parts of concentrated hydrochloric acid, 15-25 parts of sodium sulfate, 15-25 parts of perlite, 5-15 parts of sawdust, 25-35 parts of diatomaceous earth, 15-20 parts of bentonite, 10-15 parts of potassium permanganate, 20-30 parts of quaternary ammonium salt, 5-10 parts of fruit shell filter materials, 10-18 parts of medicinal stone, 15-25 parts of coconut shell activated carbon and 20-35 parts of cation exchange resin. The printing-dyeing wastewater purifier and the utilization method of the purifier have the advantages that not only can printing-dyeing wastewater with high erchrominance and higher concentration be treated, but also the printing-dyeing wastewater after the treatment of the purifier is colorless and odorless, and has obviously-reduced CODcr (Chemical Oxygen Demand chromium) value and BOD5 (Biochemical Oxygen Demand 5) value; moreover, secondary pollution can be avoided in the process of treating the printing-dyeing wastewater by utilization of the purifier, and the effects of low cost, simple operation and convenience in promotion are achieved.

Owner:临沭县环境保护局

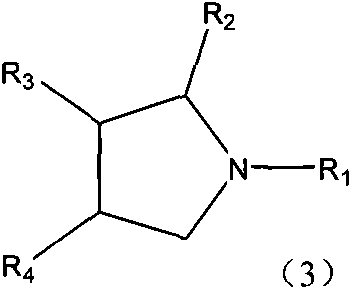

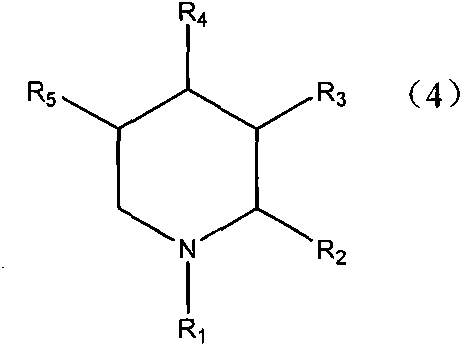

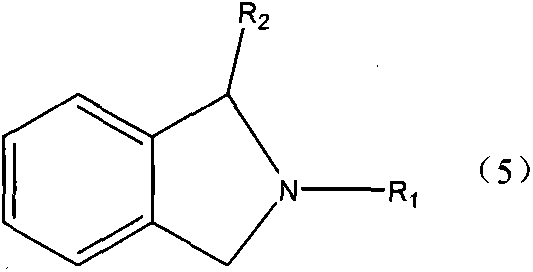

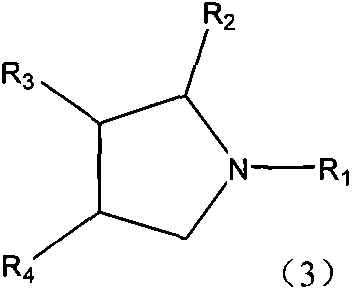

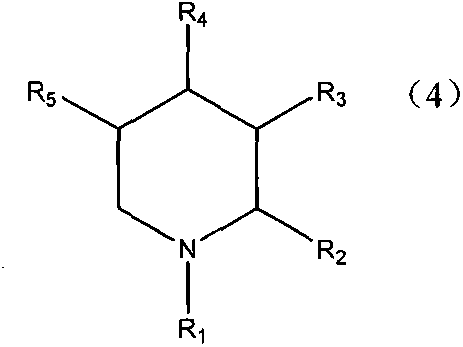

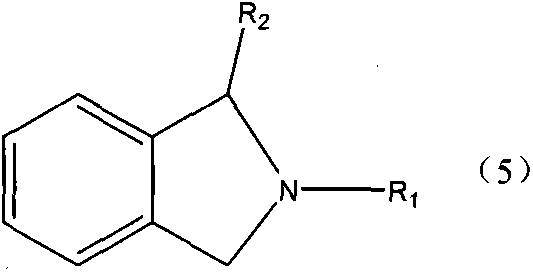

Production method of single nitrogenous heterocyclic ring-containing compound

ActiveCN105753768AEmission reductionImprove continuityOrganic chemistryNitrogenous heterocyclic compoundFatty amine

The invention discloses a production method of a single nitrogenous heterocyclic ring-containing compound. Lactone and fatty amine which are cheap and easy to obtain are used as raw materials for producing the single nitrogenous heterocyclic ring-containing compound; lactone and fatty amine are used for synthesis of amide, and hydrodeoxygenation is carried out in order to obtain the corresponding nitrogenous heterocyclic compound. The process has only two reaction steps, and has the advantages of low investment, high yield, simple separation for intermediate products, few by-products, and easy processing.

Owner:北京恒瑞新霖科技有限公司

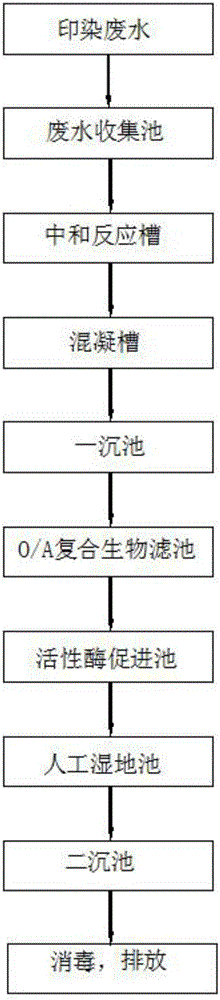

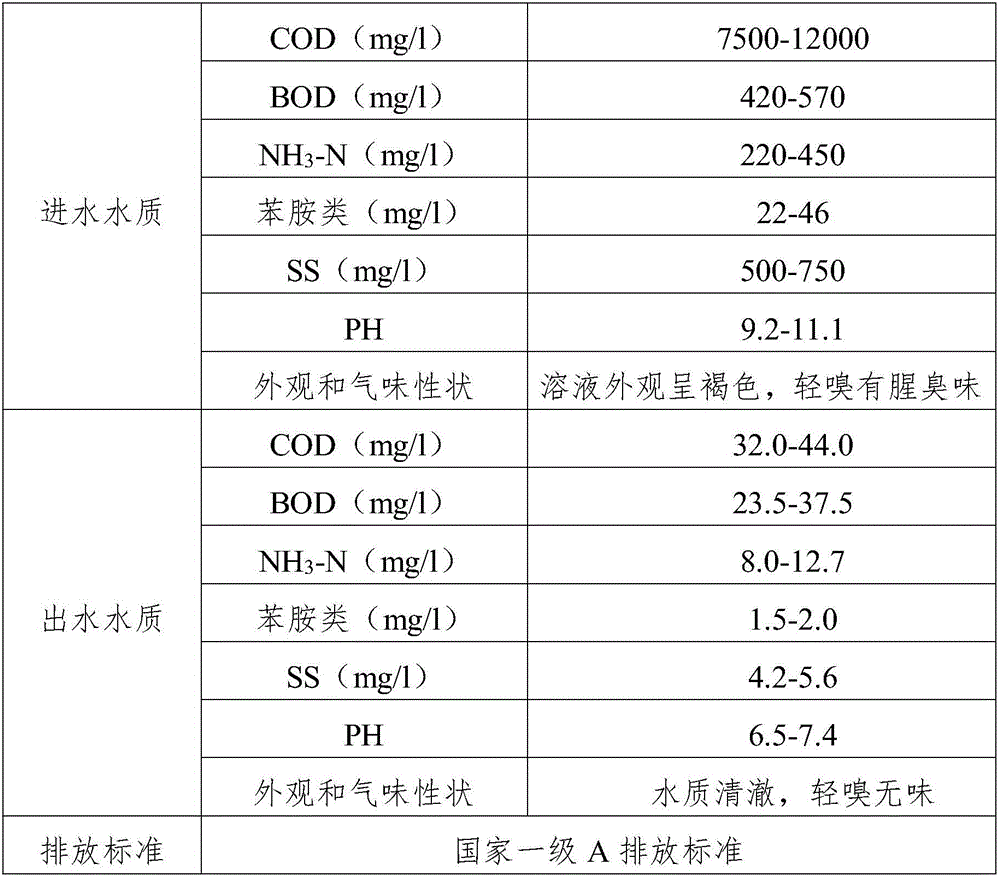

Combined process for treating textile printing and dyeing wastewater

ActiveCN105967453AReduce COD contentLow chroma valueSpecific water treatment objectivesTreatment involving filtrationTextile printerConstructed wetland

The invention relates to the technical field of treatment of textile printing and dyeing wastewater, in particular to a combined process for treating textile printing and dyeing wastewater, comprising the steps such as neutralizing, coagulating and precipitating, filtering with an O / A combined biofilter, activating with an active enzyme promoter, adsorbing with a constructed wetland tank, precipitating, sterilizing, and discharging; the combined process provided by the invention has good wastewater purifying effect and enables continuous treatment of batch production wastewater.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

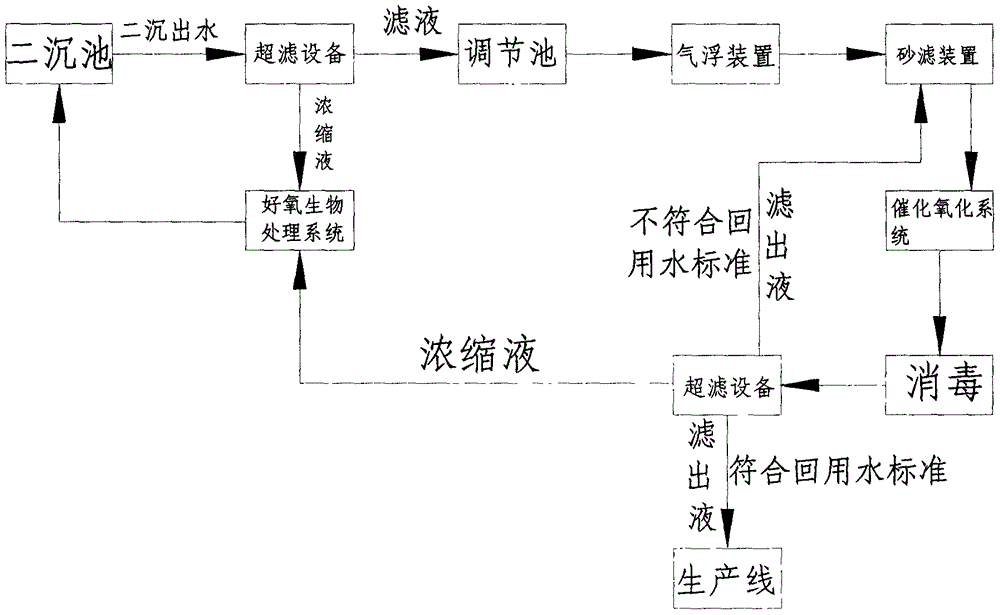

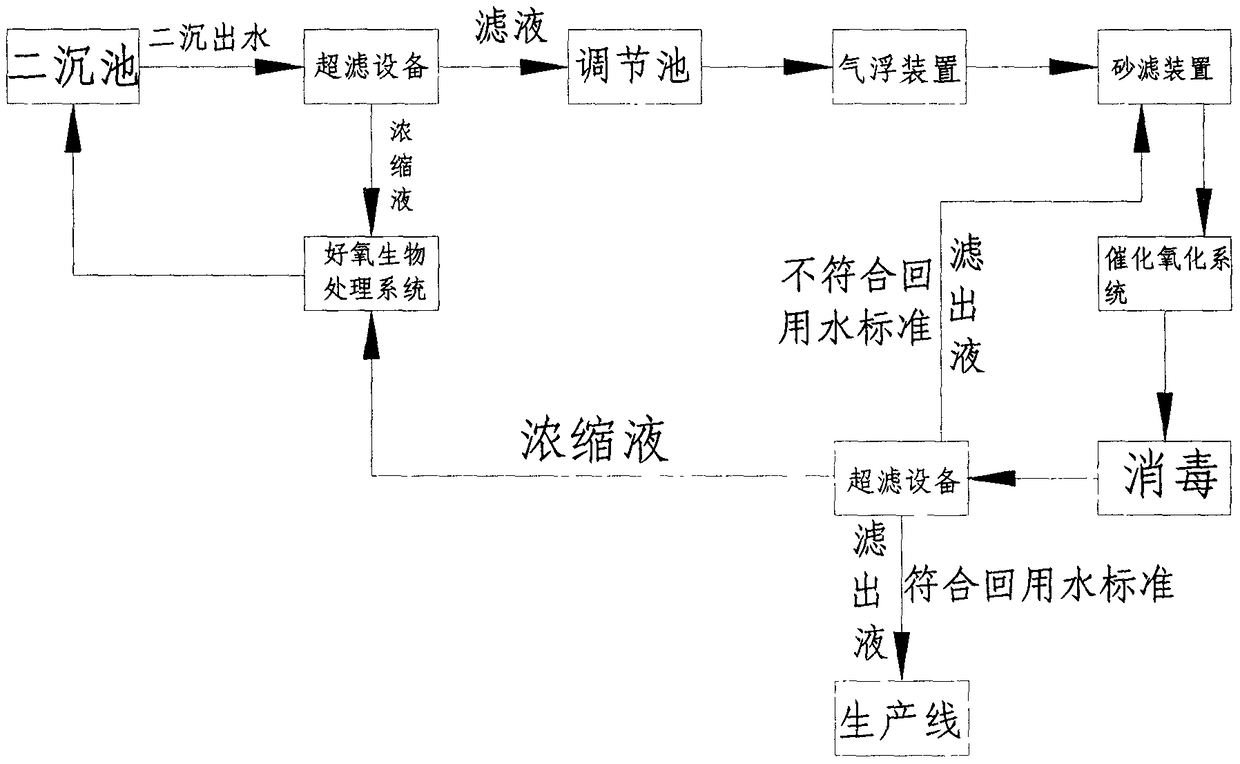

Process for advanced treatment of antibiotic waste water

ActiveCN105923931AAchieve reuseAchieve recyclingWater treatment parameter controlTreatment using aerobic processesChemical treatmentParticulates

The invention relates to a process for advanced treatment of antibiotic waste water. The process is used for further treating the waste water obtained after secondary sedimentation tank treatment during the treatment of the antibiotic waste water, and comprises the following steps: firstly, performing ultrafiltration treatment on the waste water, which is obtained after the secondary sedimentation tank treatment, in an ultrafiltration apparatus so as to filter out macromolecular particulate matters in the waste water, thereby obtaining a concentrated solution and a filtrate; and then, performing degradation treatment on the concentrated solution in an aerobic biological treatment system, delivering the concentrated solution after the degradation treatment in the aerobic biological treatment system into a secondary sedimentation tank, and treating the filtrate by a series of treatment steps of regulation, air flotation, sand filtration, catalytic oxidation, sterilization and detection to obtain recycled water which accords with a recycled water standard. The process provided by the invention combines a chemical treatment method, a physical treatment method and a membrane treatment method together, and has the advantages of short process route, good treatment effect, small produced sludge amount, low system energy consumption, low equipment operating cost, simple operation and small labor intensity.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD

Method for synthesizing brominated polystyrene

The invention relates to a method for synthesizing brominated polystyrene. The method comprises the following steps: under the protection of nitrogen, uniformly mixing a dichloroethane solution of polystyrene with a certain amount of a catalyst and a free radical inhibitor, dropwise adding bromine, controlling the dropwise adding time and the temperature after dropwise adding, carrying out a heatpreservation reaction, carrying out post-treatment after the heat preservation reaction is finished to obtain a crude product, and drying the crude product to constant weight to obtain the brominatedpolystyrene product. The method for synthesizing the brominated polystyrene is simple in process and easy to control, and the synthesized brominated polystyrene is high in stability, high in bromine content, low in chromaticity and narrow in molecular weight distribution.

Owner:TAIZHOU BAILLY CHEM CO LTD

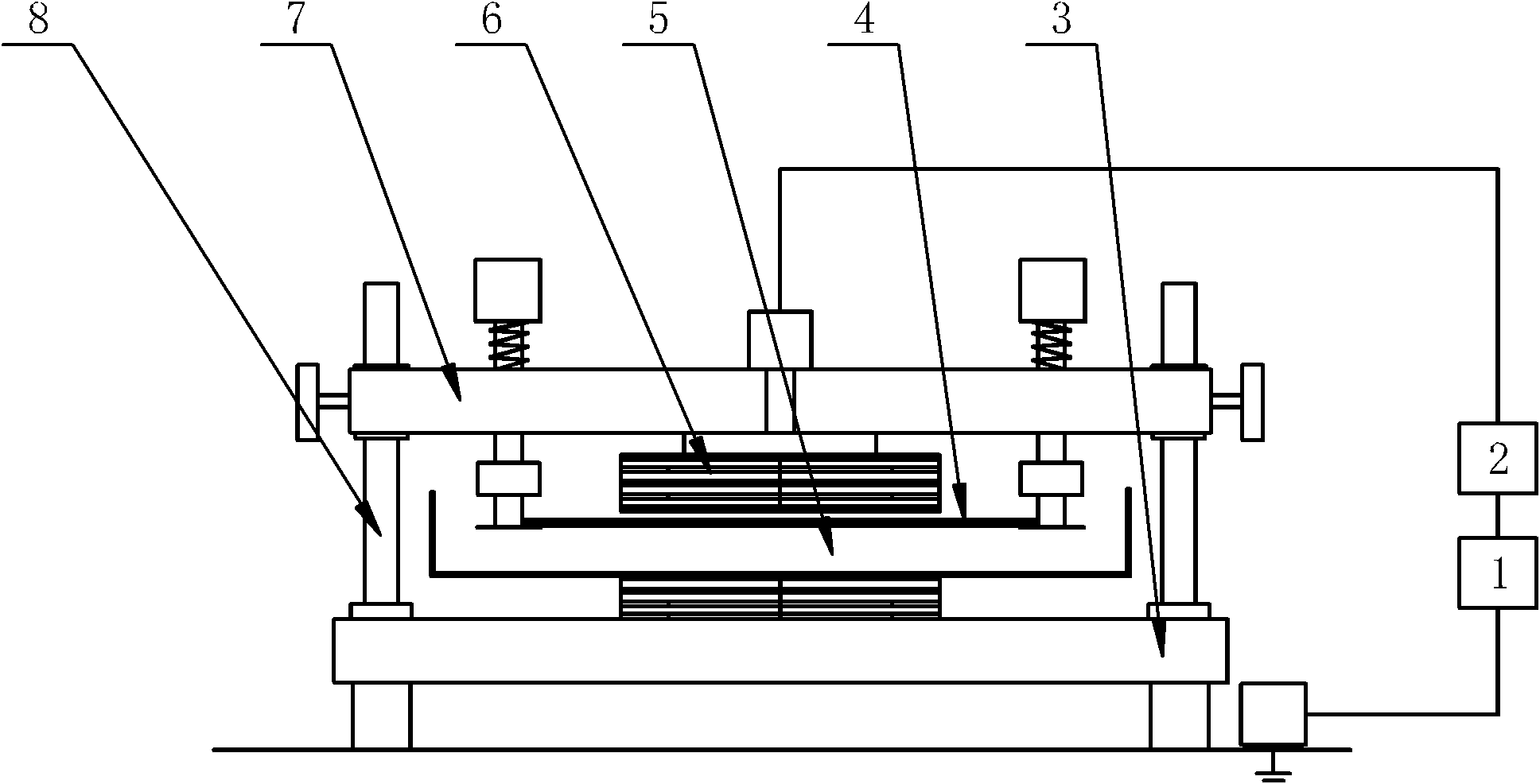

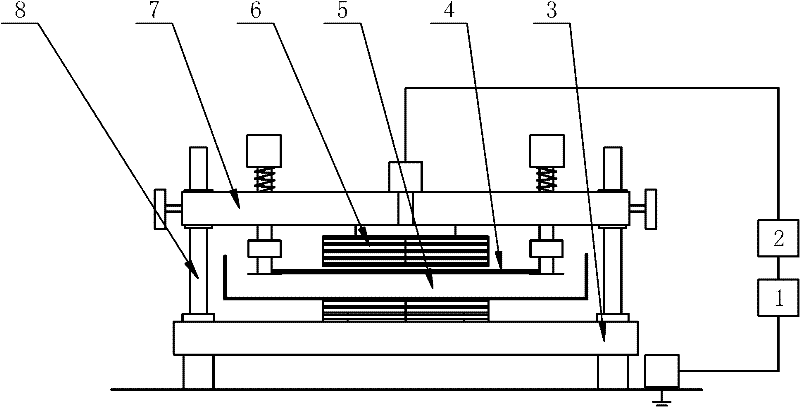

Deep treatment method for up-to-standard printing and dying industry wastewater

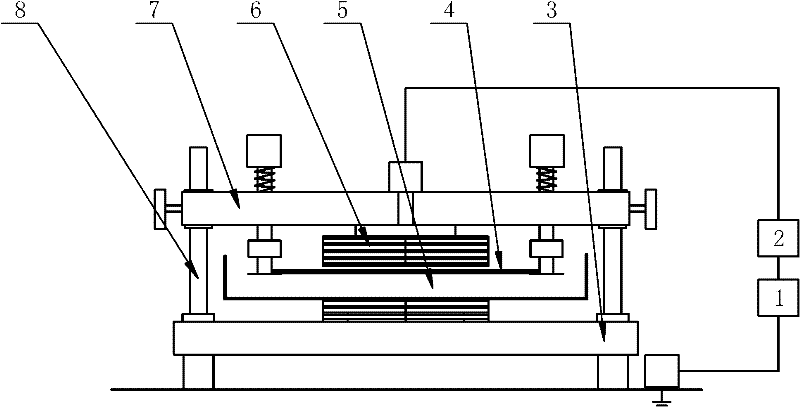

InactiveCN101863538ALow chroma valueReduce COD valueWater/sewage treatment by magnetic/electric fieldsWaste water treatment from textile industryWastewaterLow temperature plasma

The invention relates to the field of water environment pollution treatment and discloses a deep treatment method for up-to-standard printing and dying industry wastewater, which is based on a dielectric barrier discharge low-temperature plasma discharge device, and the dielectric barrier discharge low-temperature plasma discharge device can generate a low-temperature plasma environment with the temperature of 10 DEG C to 50 DEG C. The method is characterized that: an open container containing printing and dying industry wastewater coming up to the national first-grade discharge standard is placed in the low-temperature plasma environment with the temperature of 10 DEG C to 50 DEG C to carry out decolorization and degradation, wherein the depth of the printing and dying industry wastewater is 0.1cm to 1cm, the input power of the dielectric barrier discharge low-temperature plasma discharge device corresponding to each square centimeter of water surface is 0.175W to 1.364W, and the time of decolorization and degradation is 3 to 5 minutes.

Owner:XI AN JIAOTONG UNIV

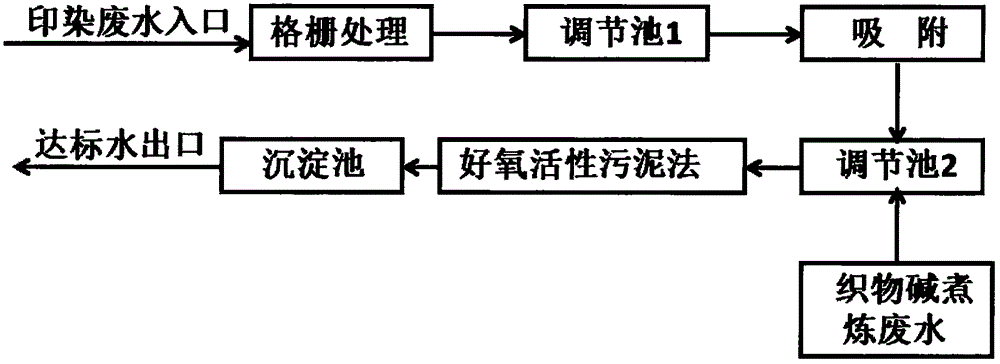

Simple process for treating wastewater containing various dyes

InactiveCN106630396AStable decolorization rateHigh discharge water qualityWater treatment parameter controlWater contaminantsActivated sludgeParticulates

The invention relates to a simple process for treating wastewater containing various dyes. The simple process is characterized by comprising the following steps: a. grate treatment: the wastewater containing multiple disperse dyes is subjected to grate treatment to remove large particles and then enters an adjusting tank 1; b, pH value adjustment: industrial hydrochloric acid is used to adjust pH of wastewater to 3-5, and then the wastewater enters an adsorption tank; c. desilted sludge adsorption: the desilted sludge is fed to the adsorption tank in advance; a mass-volume ratio of the desilted sludge to water is 6-10 kg / m3; the colority removal rate of the wastewater after adsorption treatment reaches 98%; the COD removal rate is 20-35%; d, treatment with an aerobic activated sludge method: supernatant after settlement enters an adjusting tank 2, is mixed with fabric base boiled and smelted wastewater until the pH is 6-8, then is pumped into the aeration tank, and is treated by the aerobic activated sludge method in the aeration tank, wherein the hydraulic retention time is 12 hours.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Starch phosphate-containing papermaking wastewater treatment agent

InactiveCN103435138ALow chroma valueReduce the value of suspended matterWater/sewage treatment by flocculation/precipitationPhosphatePhosphoric acid

The invention discloses a starch phosphate-containing papermaking wastewater treatment agent. The treatment agent consists of the following components in parts by weight: 5-10 parts of starch phosphate, 2-3 parts of polymeric phosphate-ferric chloride, 3-4 parts of polyethyleneimine, 7-9 parts of active carbon, 5-8 parts of magnesium carbonate and 155-165 parts of water. The prepared starch phosphate-containing papermaking wastewater treatment agent can be used for quickly reducing the chromaticity and the suspension content in the papermaking wastewater and reducing the total amount of pollutants in the papermaking wastewater.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

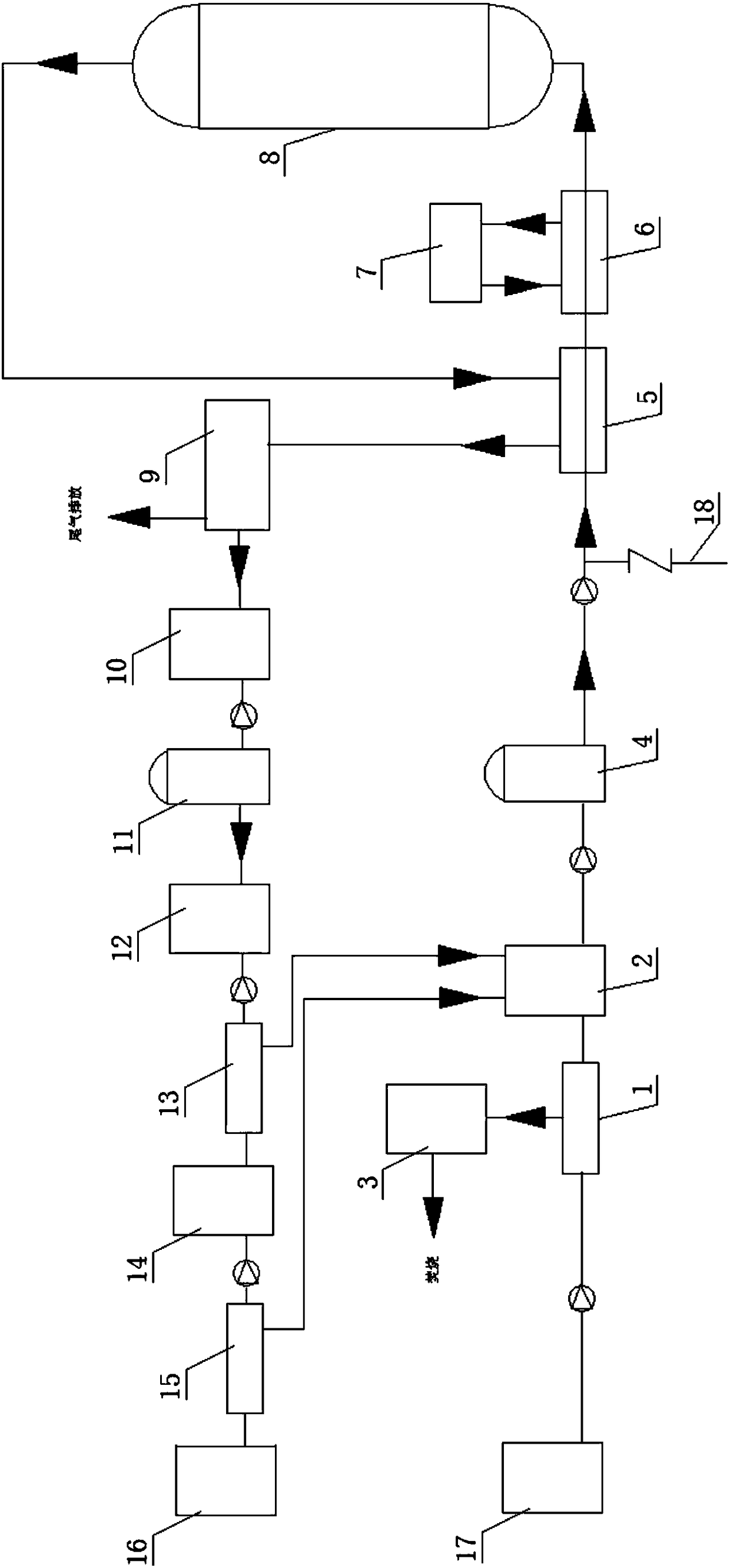

Method and apparatus for treating high-concentration emulsion wastewater

PendingCN108249614AImprove stabilityStrong impact resistanceWater contaminantsWater/sewage treatment bu osmosis/dialysisHigh concentrationChemical treatment

The invention discloses a method for treating high-concentration emulsion wastewater. The comprises the following steps: the high-concentration emulsion wastewater is filtered by an inorganic membraneto perform oil-water separation in order to obtain an inorganic membrane liquid concentrate and a clear liquid; the clear liquid enters a catalytic oxidation system and undergoes catalytic oxidationtreatment; catalytic oxidation treatment effluent is adsorbed by activated carbon, enters an ultrafiltration membrane device, and is ultrafiltered to obtain an ultrafiltered liquid concentrate and ultrafiltration membrane effluent; the ultrafiltered liquid concentrate returns to the catalytic oxidation system, and is mixed with a supernatant, and the obtained mixture is oxidized; and the ultrafiltration membrane effluent enters a reverse osmosis membrane device, and undergoes reverse osmosis treatment to obtain a reverse osmosis liquid concentrate and a permeate, and the reverse osmosis liquidconcentrate returns to the catalytic oxidation system and is oxidized. The inorganic membrane adopted in the method can resist high oil and high solid content treatment during separation, and the whole system has a good stability and a strong impact resistance; and a catalytic oxidation technology adopts a small amount of reagents, is a pure chemical treatment technology, and does not produce liquid concentrate, sludge or other pollutants.

Owner:NANJING YUANQUAN TECH CO LTD

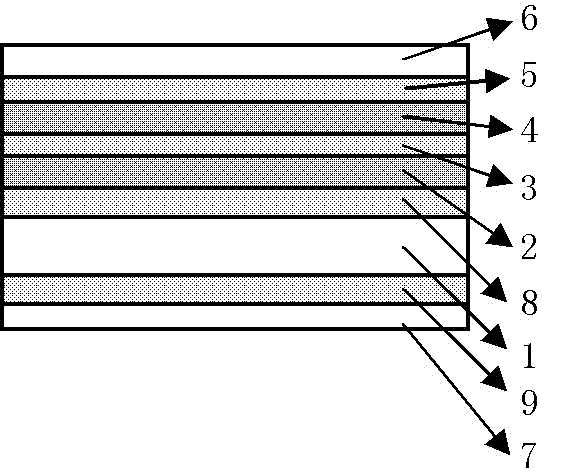

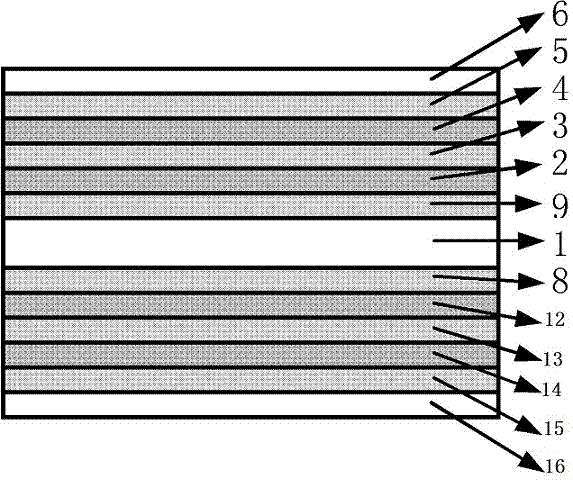

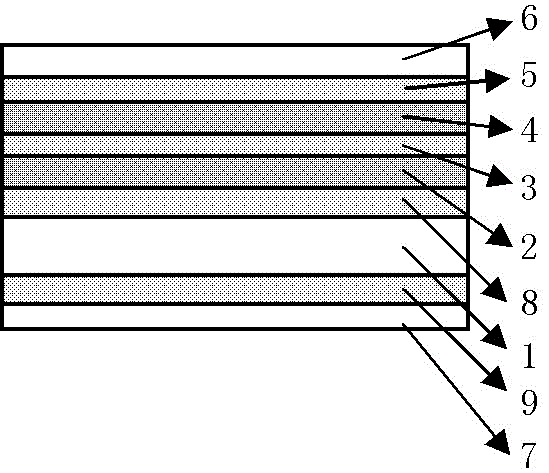

Capacitive touch screen with flexible transparent conductive film and production method thereof

ActiveCN102830876ASmall thicknessReduce weightInput/output processes for data processingSputteringIndium tin oxide

The invention provides a capacitive touch screen and a production method thereof. The capacitive touch screen is flexible, curlable, thin, light, low in surface resistance, highly light-permeable and low in chroma. The capacitive touch screen comprises a flexible transparent film substrate. By reactive magnetron sputtering, a first Nb2O5 film layer, a first Nb2Ox(0<x<5) film layer, a first SiO2 film layer, a first SiOx(0<x<2) film layer and a first ITO (indium tin oxide) layer are sequentially deposited on the upper surface of the flexible transparent film substrate; and a second ITO film layer is arranged on the lower surface of the flexible transparent film substrate.

Owner:高邮市汇金新材料科技有限公司

Composite adsorption treatment material for wastewater with nitrobenzene

InactiveCN105688854AGood adsorption effectLow chroma valueOther chemical processesWater contaminantsFiberChemical oxygen demand

The invention discloses a composite adsorption treatment material for wastewater containing nitrobenzene, which comprises the following raw materials in parts by mass: 15-30 parts of hydroxypropyl cellulose graft copolymer, 5-8 parts of oxyferric chloride, 4~10 parts of cationic etherified starch, 2~8 parts of activated carbon fiber, 5~10 parts of activated alumina, 2~6 parts of polyepichlorohydrin, 1~4 parts of porous hydroxyapatite powder, hydrophobic modified wood 5~12 parts of cellulose fiber, 6~10 parts of polyhydroxyaluminum silicon chloride, 10~18 parts of nonionic polyacrylamide and 12~20 parts of adsorbent NSUL-1. A composite adsorption treatment material for the treatment of nitrobenzene-containing wastewater provided by the present invention produces a synergistic adsorption treatment effect through reasonable raw material compounding, and has good performance on the main pollutant in nitrobenzene-containing wastewater-nitrobenzene The adsorption treatment effect, and can effectively reduce the chroma value and COD of sewage, with excellent comprehensive water treatment effect.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

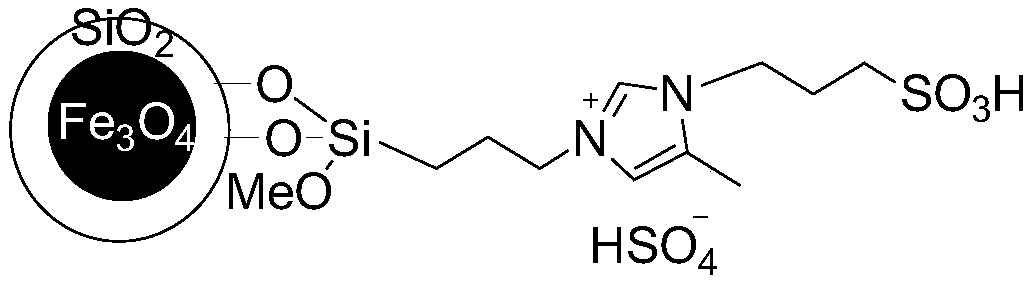

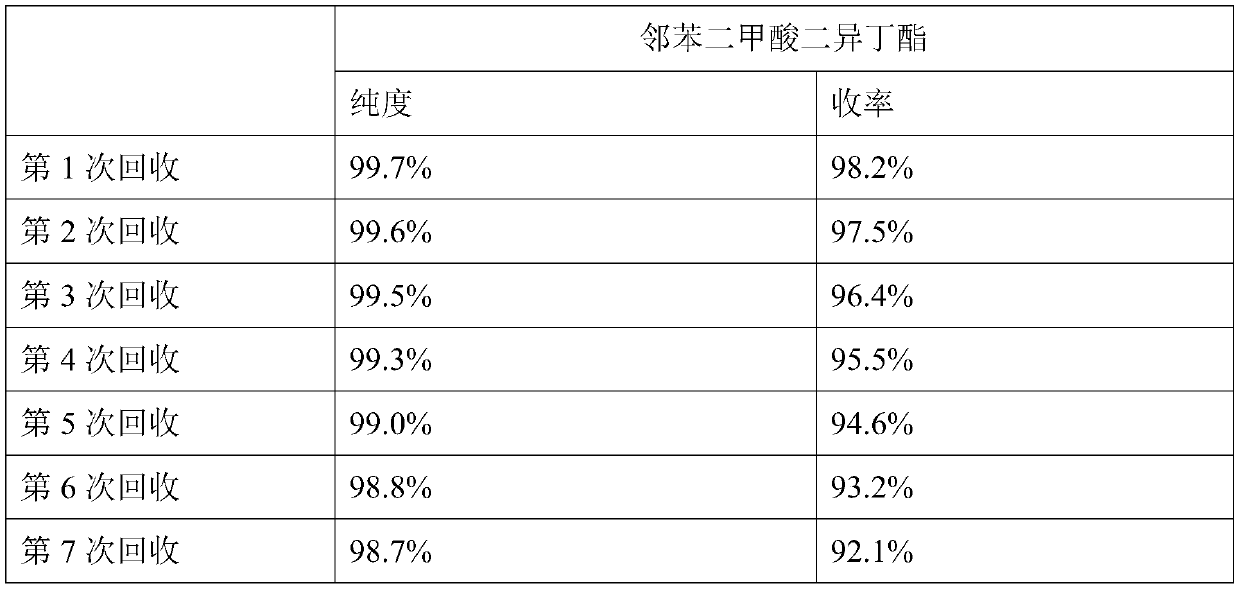

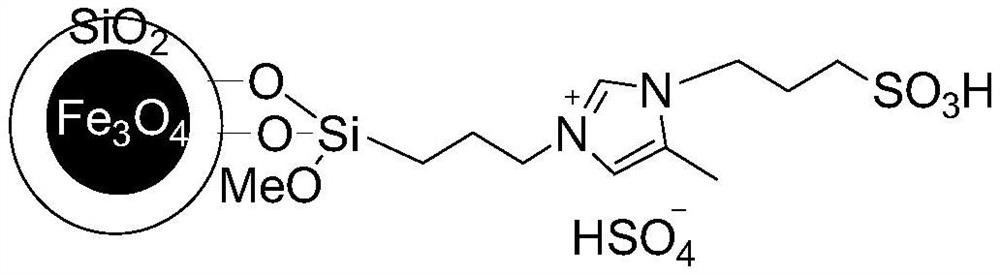

Method for preparing diisobutyl phthalate

ActiveCN110330428AEasy to recycleGood repeatabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolWater discharge

The invention discloses a method for preparing diisobutyl phthalate. The method comprises the following steps: 1, preparing a magnetic nanoparticle-supported acidic ionic liquid used as a catalyst; and 2, preparing the diisobutyl phthalate: carrying out refluxing dehydration condensation on phthalic anhydride and isobutanol under the catalysis of the magnetic nanoparticle-supported acidic ionic liquid for 3-6 h to obtain a diisobutyl phthalate reaction solution, cooling the reaction solution to room temperature, filtering the cooled reaction solution, adsorbing the obtained filtrate I by a solid alkali, performing filtration to obtain a filtrate II and a filter cake respectively, and carrying out reduced pressure dealcoholysis on the filtrate II to obtain the diisobutyl phthalate. The magnetic nanoparticle-supported acidic ionic liquid is used as the catalyst to achieve catalytic synthesis of the diisobutyl phthalate, so the method has the characteristics of high catalysis efficiency,easiness in recovery and reuse of the catalyst, simple process and less waste water discharge.

Owner:ZHEJIANG JIANYE CHEM +1

The method for preparing diisobutyl phthalate

ActiveCN110330428BEasy to recycleGood repeatabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMagnetite Nanoparticles

The invention discloses a method for preparing diisobutyl phthalate, which comprises the following steps: 1. preparing an acidic ionic liquid loaded with magnetic nanoparticles as a catalyst; 2. preparing diisobutyl phthalate: Under the catalysis of nanoparticle-loaded acidic ionic liquid, phthalic anhydride and isobutanol are refluxed for 3 to 6 hours to obtain diisobutyl phthalate reaction liquid; after the reaction liquid is cooled to room temperature, it is filtered, and the obtained The filtrate Ⅰ is adsorbed by solid alkali and filtered to obtain filtrate Ⅱ and filter cake respectively; the filtrate Ⅱ is dealcoholized under reduced pressure to obtain diisobutyl phthalate. The invention uses the acidic ionic liquid supported by magnetic nanoparticles as a catalyst to catalyze the synthesis of diisobutyl phthalate, and has the characteristics of high catalytic efficiency, easy recycling of the catalyst, simple and convenient process, less waste water discharge and the like.

Owner:ZHEJIANG JIANYE CHEM +1

Energy-saving flexible transparent conductive film and preparation method thereof

ActiveCN104651791BHigh light transmittanceLow resistivityVacuum evaporation coatingSputtering coatingOxygenVacuum coating

Owner:高邮市汇金新材料科技有限公司

A kind of production method of single nitrogen-containing heterocyclic compound

ActiveCN105753768BReduce water contentReduce energy consumptionOrganic chemistryNitrogenous heterocyclic compoundFatty amine

Owner:北京恒瑞新霖科技有限公司

Deep treatment method for up-to-standard printing and dying industry wastewater

InactiveCN101863538BLow chroma valueWater/sewage treatment by magnetic/electric fieldsWaste water treatment from textile industryWastewaterEngineering

The invention relates to the field of water environment pollution treatment and discloses a deep treatment method for up-to-standard printing and dying industry wastewater, which is based on a dielectric barrier discharge low-temperature plasma discharge device, and the dielectric barrier discharge low-temperature plasma discharge device can generate a low-temperature plasma environment with the temperature of 10 DEG C to 50 DEG C. The method is characterized that: an open container containing printing and dying industry wastewater coming up to the national first-grade discharge standard is placed in the low-temperature plasma environment with the temperature of 10 DEG C to 50 DEG C to carry out decolorization and degradation, wherein the depth of the printing and dying industry wastewater is 0.1cm to 1cm, the input power of the dielectric barrier discharge low-temperature plasma discharge device corresponding to each square centimeter of water surface is 0.175W to 1.364W, and the time of decolorization and degradation is 3 to 5 minutes.

Owner:XI AN JIAOTONG UNIV

Advanced treatment process for antibiotic wastewater

ActiveCN105923931BAchieve reuseAchieve recyclingWater treatment parameter controlTreatment using aerobic processesChemical treatmentParticulates

The invention relates to a process for advanced treatment of antibiotic waste water. The process is used for further treating the waste water obtained after secondary sedimentation tank treatment during the treatment of the antibiotic waste water, and comprises the following steps: firstly, performing ultrafiltration treatment on the waste water, which is obtained after the secondary sedimentation tank treatment, in an ultrafiltration apparatus so as to filter out macromolecular particulate matters in the waste water, thereby obtaining a concentrated solution and a filtrate; and then, performing degradation treatment on the concentrated solution in an aerobic biological treatment system, delivering the concentrated solution after the degradation treatment in the aerobic biological treatment system into a secondary sedimentation tank, and treating the filtrate by a series of treatment steps of regulation, air flotation, sand filtration, catalytic oxidation, sterilization and detection to obtain recycled water which accords with a recycled water standard. The process provided by the invention combines a chemical treatment method, a physical treatment method and a membrane treatment method together, and has the advantages of short process route, good treatment effect, small produced sludge amount, low system energy consumption, low equipment operating cost, simple operation and small labor intensity.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD

A kind of capacitive touch screen with flexible transparent conductive film and preparation method thereof

ActiveCN102830876BSmall thicknessReduce weightInput/output processes for data processingSputteringIndium tin oxide

The invention provides a capacitive touch screen and a production method thereof. The capacitive touch screen is flexible, curlable, thin, light, low in surface resistance, highly light-permeable and low in chroma. The capacitive touch screen comprises a flexible transparent film substrate. By reactive magnetron sputtering, a first Nb2O5 film layer, a first Nb2Ox(0<x<5) film layer, a first SiO2 film layer, a first SiOx(0<x<2) film layer and a first ITO (indium tin oxide) layer are sequentially deposited on the upper surface of the flexible transparent film substrate; and a second ITO film layer is arranged on the lower surface of the flexible transparent film substrate.

Owner:高邮市汇金新材料科技有限公司

A production process and device for direct edible syrup

ActiveCN103710469BLow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansMicrofiltration membraneTower

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

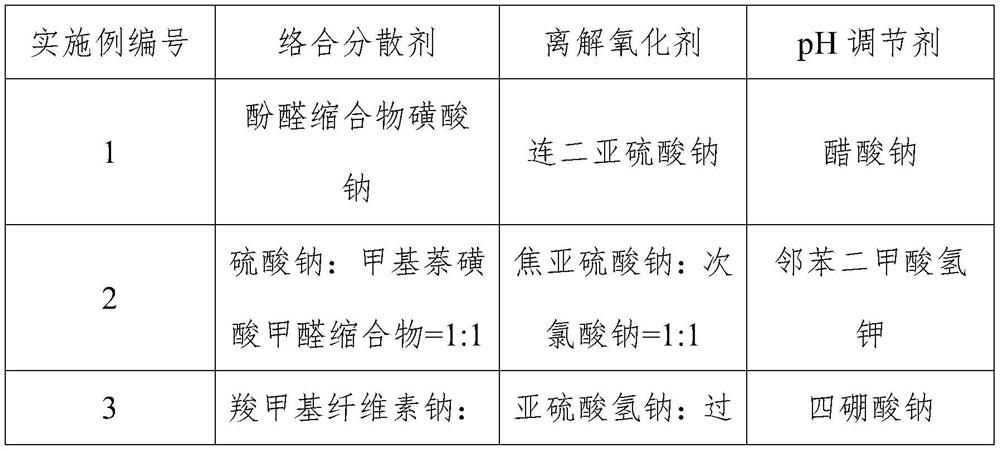

Printing and dyeing wastewater regenerant as well as preparation method and use method thereof

ActiveCN114291885AReduce chromaLow chroma valueWater contaminantsWater/sewage treatment by oxidationWater savingPulp and paper industry

The invention discloses a printing and dyeing wastewater regenerant as well as a preparation method and a use method thereof, the printing and dyeing wastewater regenerant is applied to printing and dyeing wastewater of reactive dyes and comprises the following components in percentage by mass: 0.1-2% of a dye molecular cluster complexing dispersant, 0.1-20% of a chromophoric group targeted positioning dissociation oxidant and 0.1-3% of a pH regulator. The printing and dyeing wastewater regenerant prepared by the invention can effectively reduce the conventional reactive dye soaping post-treatment operation procedures, and has remarkable water-saving, energy-saving and emission-reducing benefits.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Pretreatment method of oil-containing organic wastewater

PendingCN112624393AReduce chromaLow chroma valueWater treatment parameter controlWater contaminantsIron saltsPretreatment method

The invention belongs to the field of oil-containing wastewater treatment, and discloses a pretreatment method of oil-containing organic wastewater. The method comprises the steps of regulating the pH value of the oil-containing organic wastewater to 6-9; adding an iron salt or an iron salt polymer into the oil-containing organic wastewater of which the pH value is adjusted, and mechanically stirring for the first time to obtain a first mixture system; adding a polyacrylamide solution into the first mixture system, and carrying out second mechanical stirring to obtain a second mixture system; adjusting the pH value of the second mixture system to 3-5 while carrying out secondary mechanical stirring on the second mixture system to obtain a third mixture system; and filtering the third mixture system to obtain filtrate. According to the pretreatment method of the oil-containing organic wastewater, oil substances and solid particles in the oil-containing organic wastewater can be removed, the chromaticity can be reduced, the pretreated effluent can meet the requirements of a subsequent process on the quality of inflow water, and adverse effects on the subsequent wastewater treatment process are avoided.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

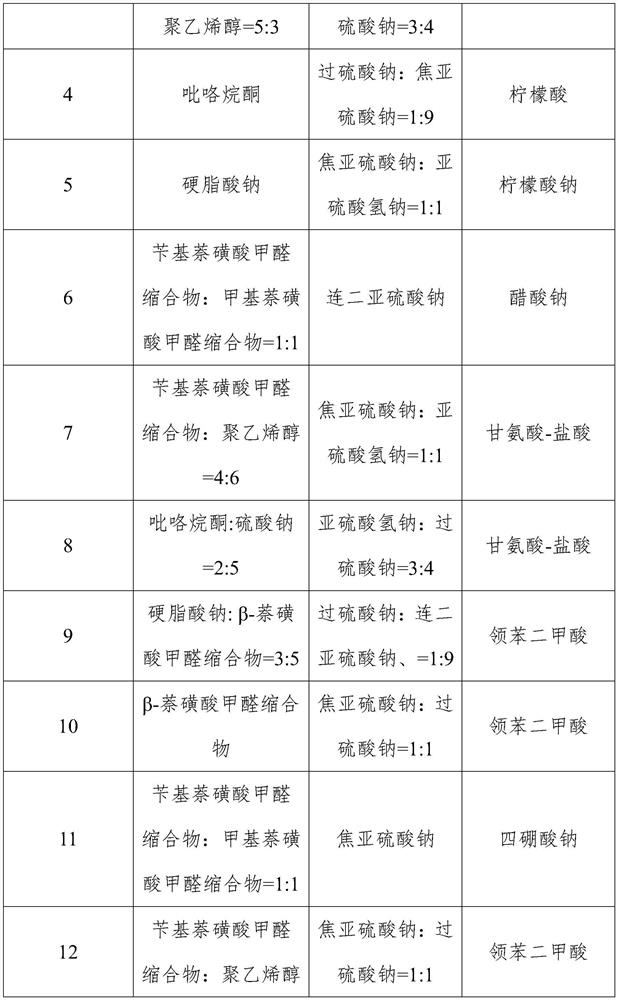

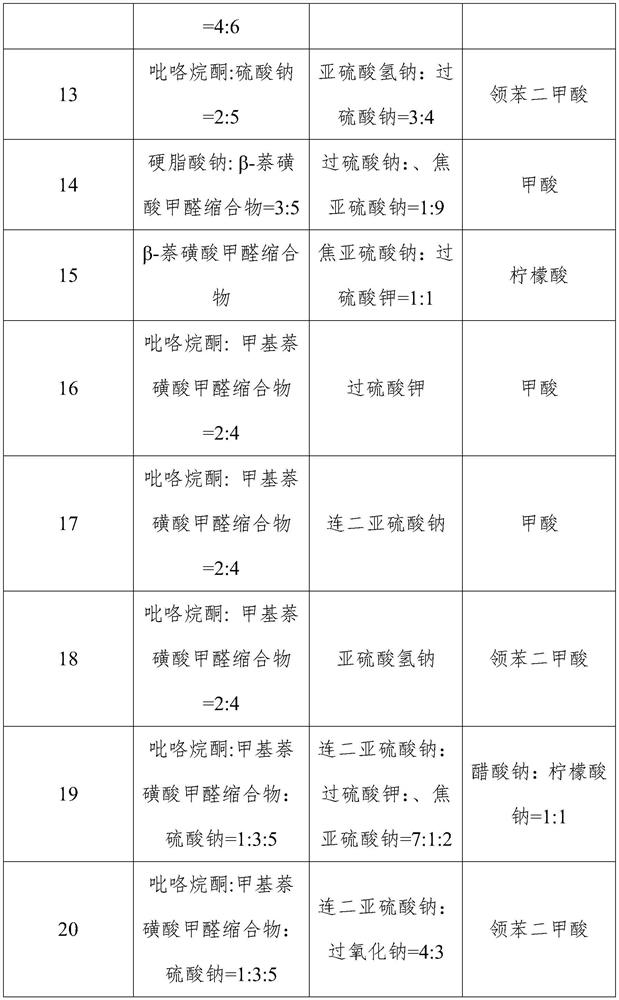

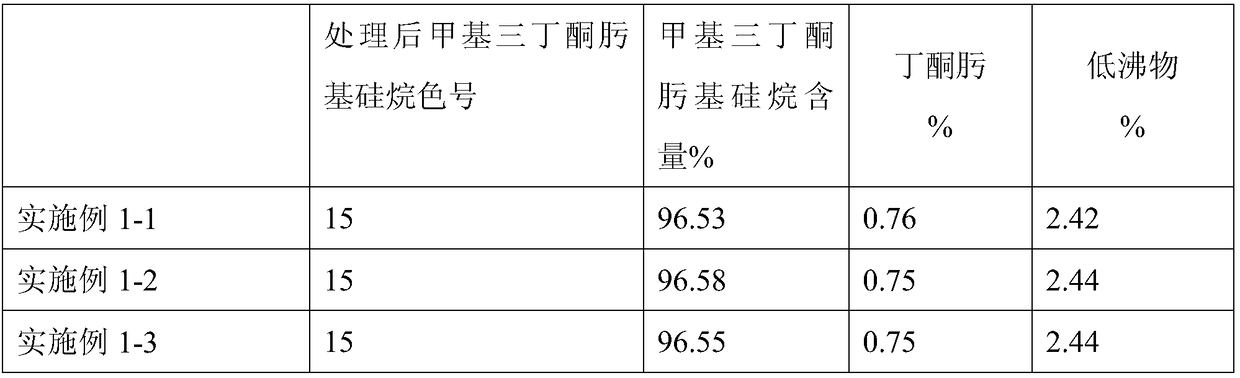

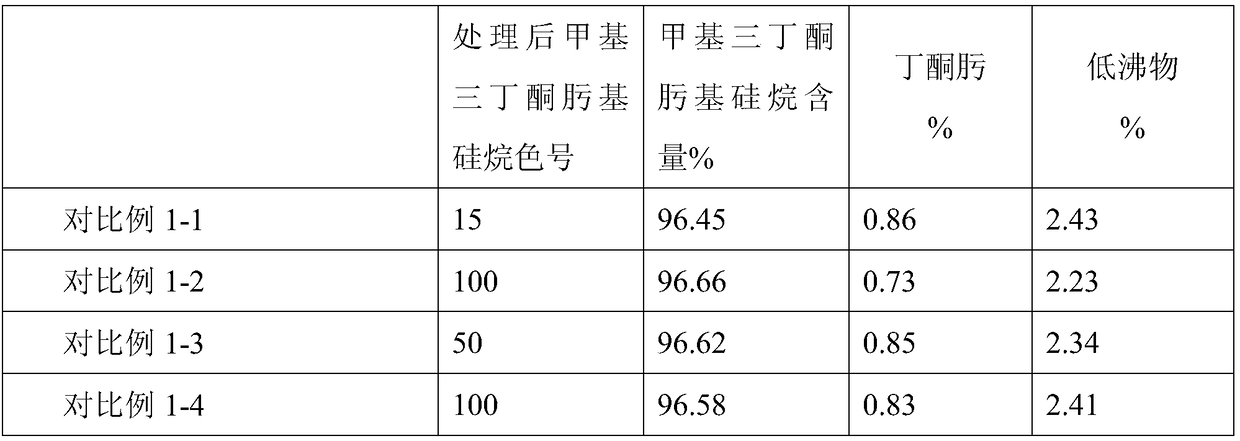

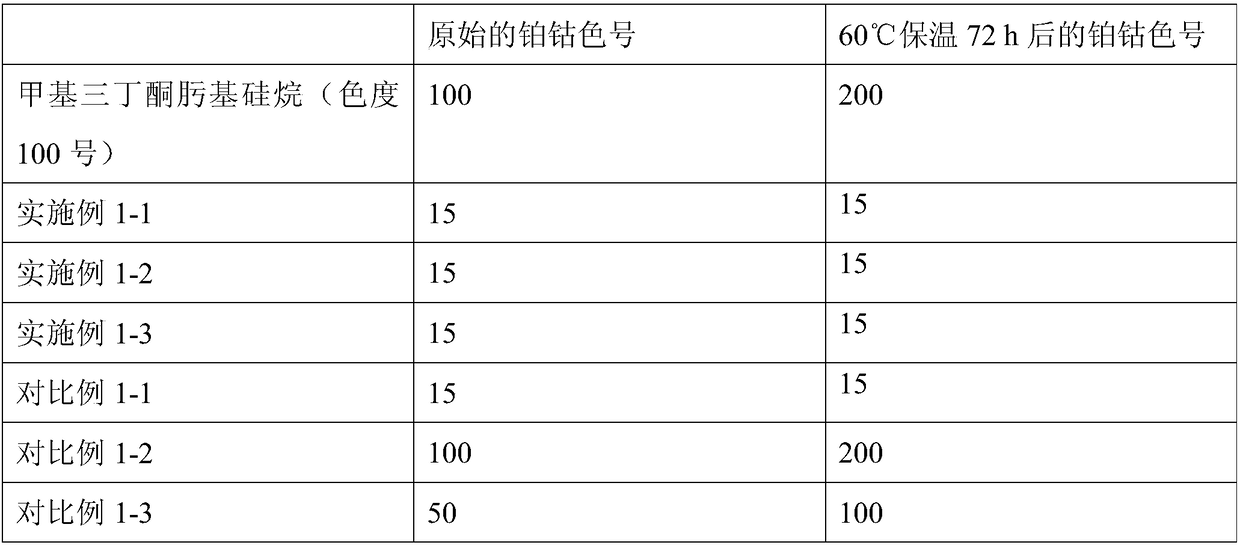

Decolorization method of ketoxime type silane crosslinking agent

The invention discloses a decolorizing method for a ketoxime type silane crosslinking agent. The decolorizing method comprises the following steps: (1) modification of decolorized attapulgite clay: dipping the decolorized attapulgite clay with ketoxime-based silane, adding water in the decolorized attapulgite clay for dispersing treatment, filtering, washing a filter cake I, and roasting and activating the filter cake I to obtain modified decolorized attapulgite clay; and (2) decolorizing: sieving the modified decolorized attapulgite clay, dispersing the sieved modified decolorized attapulgite clay in high-chroma ketoxime-based silane to be treated, stirring for 0.5-3 hours at constant temperature, and filtering to obtain filtrate which is low-chroma ketoxime-based silane.

Owner:江苏艾科维科技股份有限公司

Dyeing low-temperature post-treatment auxiliary of pure polyester fabric and polyester-containing fabrics and post-treatment technology thereof

The invention discloses a dyeing low-temperature post-treatment auxiliary of a pure polyester fabric and polyester-containing fabrics and a post-treatment technology thereof. The post-treatment auxiliary is prepared from the following components: 300-600 g / kg of rongalite, 50-400 g / kg of biological enzyme and 100-500 g / kg of Gemini cationic surface active agent. By compounding the dyeing post-treatment auxiliary of the polyester fabric or the polyester-containing fabric, then using the post-treatment auxiliary for conducting dyeing low-temperature post-treatment on the polyester fabric or thepolyester-containing fabric, and using a synergistic effect mechanism among the three components, low-temperature post-treatment processing is conducted on of the polyester fabric or the polyester-containing fabric is realized, the defect that traditionally, the polyester fabric or the polyester-containing fabric needs to be subjected to post-treatment under a high temperature condition is overcome, dye which is washed into a solution does not stain the fabrics any more, moreover, post-treatment printing and dyeing wastewater is colorless, which is beneficial for wastewater treatment, and thefabrics subjected to post-treatment have soft hand feelings, and are excellent in fastness.

Owner:湖南中翔化学科技有限公司

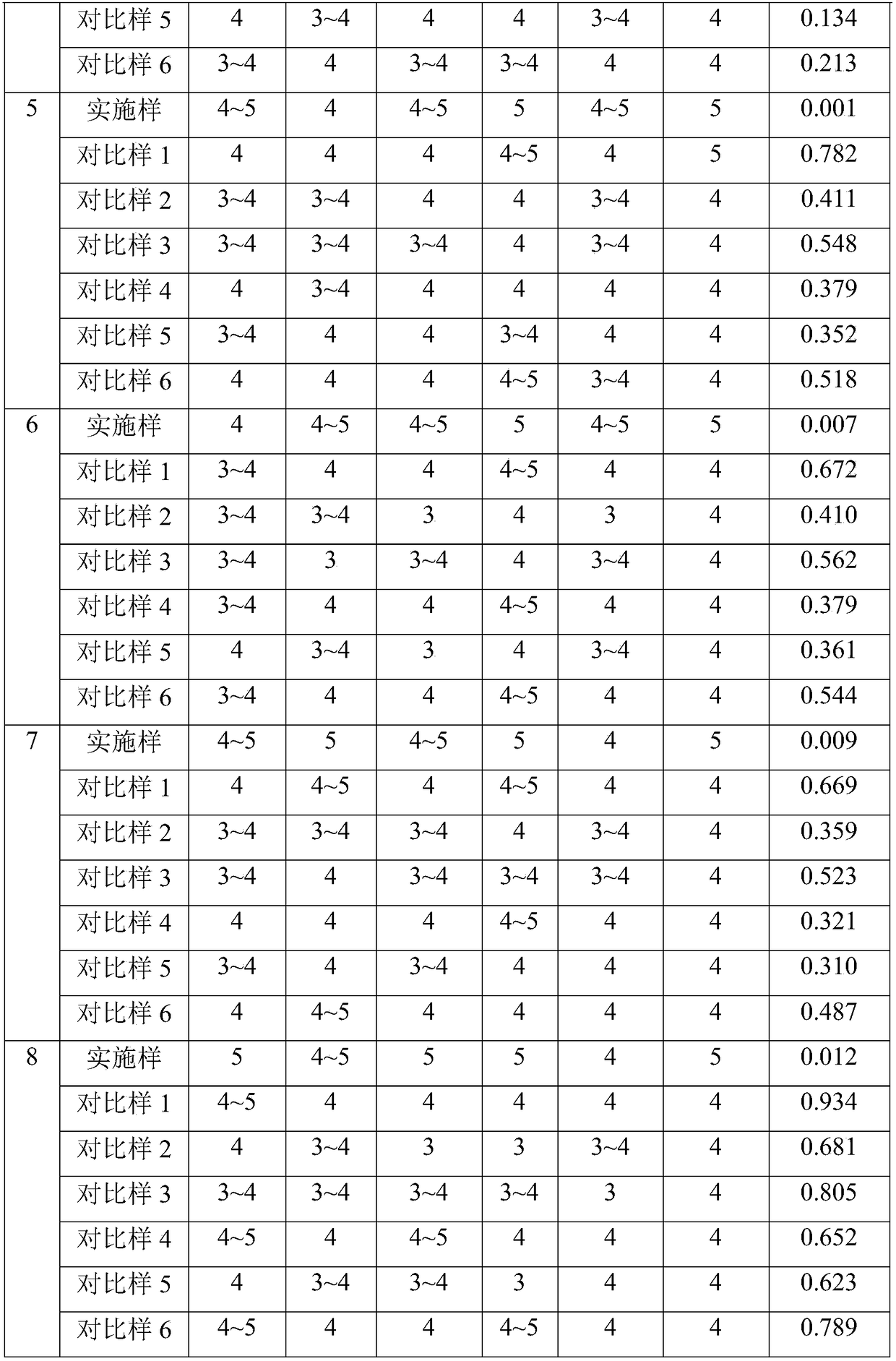

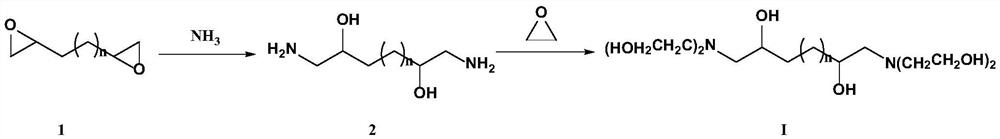

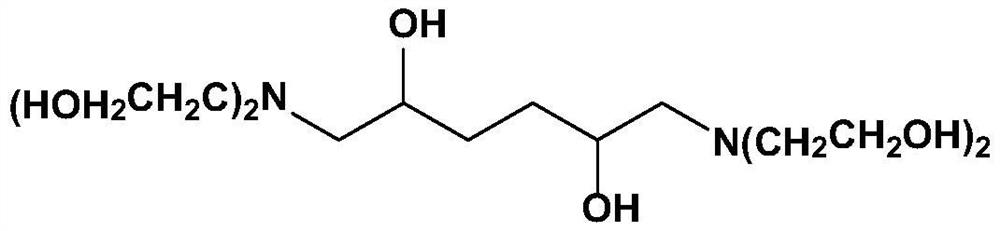

A kind of preparation method of alkanolamine

ActiveCN113402401BImprove catalytic performanceEasy to separatePhysical/chemical process catalystsOrganic compound preparationPtru catalystPhysical chemistry

The present invention relates to a kind of preparation method of alkanolamine. The preparation method of the present invention does not need to use expensive noble metal catalysts, and does not introduce chloride ions into the product, and can obtain products with high purity and low chromaticity in high yield, and has high atom economy, and the three wastes are very low. Less, high environmental protection, suitable for industrial applications.

Owner:FUJIAN FURUN BUILDING MATERIAL TECH

Environment-friendly water purifying agent

InactiveCN111186894ALow chroma valueLow costWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationSilicic acidPolyacrylamide

The invention provides an environment-friendly water purifying agent which comprises the following components in parts by mass: 5-8% of aluminum sulfate, 5-8% of ferrous sulfate, 10-12% of sodium hypochlorite, 8-13% of tourmaline powder, 8-10% of active silicic acid, 8-12% of zinc oxide, 4-6% of polyacrylamide, and 3-5% of a pH value regulator, with the balance being deionized water. The water purifying agent prepared by the invention not only can treat wastewater with higher chromaticity and concentration, but also can enable the wastewater treated by the water purifying agent to be colorless, odorless and obviously lower in suspended matter and chromaticity value. In addition, no secondary pollution is generated in the process of treating wastewater by using the water purifying agent, and the water purifying agent is low in cost, simple to operate and convenient to popularize.

Owner:南通佳烁环保科技有限公司

A kind of method of synthesizing brominated polystyrene

The invention relates to a method for synthesizing brominated polystyrene. Under the condition of nitrogen protection, polystyrene dichloroethane solution is uniformly mixed with a certain amount of catalyst and free radical inhibitor, and then bromine is added dropwise to control its Dropping time, temperature after dropping, and then heat preservation reaction. After heat preservation reaction, post-treatment is carried out to obtain a crude product. The crude product is dried to constant weight to obtain the product brominated polystyrene. The method for synthesizing brominated polystyrene has the advantages of simple process and easy control, and the synthesized brominated polystyrene has high stability, high bromine content, low chroma and narrow molecular weight distribution.

Owner:TAIZHOU BAILLY CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com