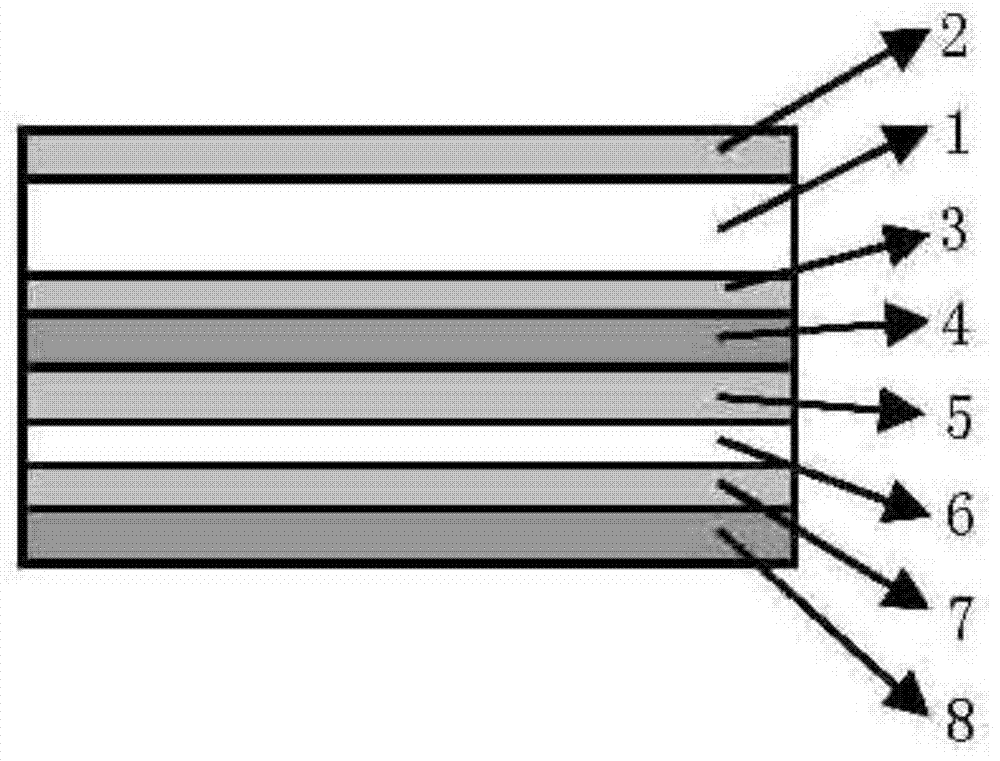

Energy-saving flexible transparent conductive film and preparation method thereof

A transparent conductive film, energy-saving technology, applied in chemical instruments and methods, ion implantation plating, coating, etc., can solve problems such as increasing energy consumption, and achieve the advantages of reducing energy consumption, high sensitivity, and reducing high-temperature annealing processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

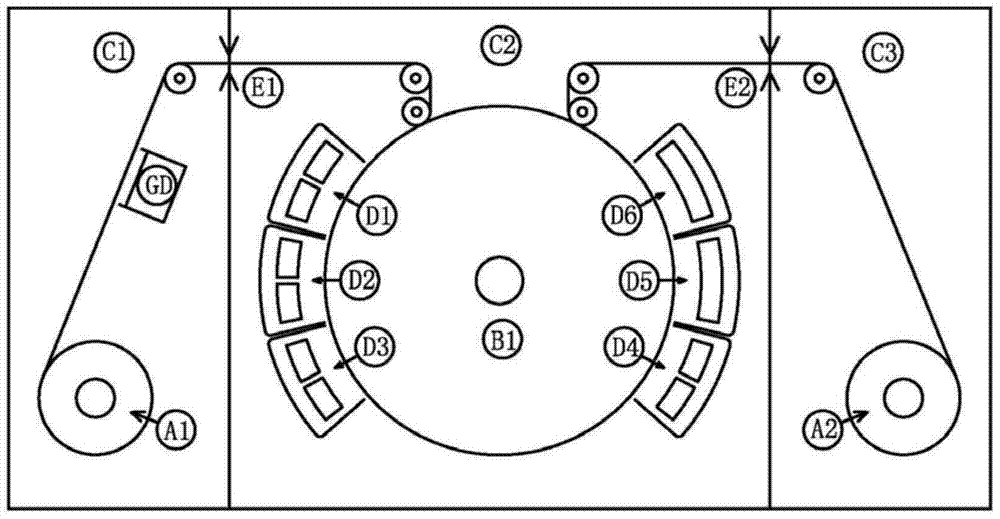

[0031] see figure 2 Shown is a device for preparing energy-saving flexible transparent conductive films, which includes a chamber with an unwinding chamber C1, a coating chamber C2 and a winding chamber C3, and an unwinding roller A1 and glow discharge ion surface treatment are arranged in the unwinding chamber Machine GD, the winding roll A2 is set in the winding cavity, and the cooling roll B1 is set in the coating cavity. A vacuum holding valve device E1 is provided on the cavity wall between the unwinding cavity and the coating cavity, and on the cavity wall between the winding cavity and the coating cavity. The unwinding chamber, the coating chamber and the winding chamber all have a vacuum pump for evacuating and an inflating tube for filling inert gas.

[0032] The first, second, third, fourth, fifth, and sixth magnetron sputtering devices (target machines) D1, D2, D3, D4, D5, and D6 are set around the cooling roller; the flexible transparent substrate is cooled after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com