Deep treatment method for up-to-standard printing and dying industry wastewater

A technology for advanced treatment of printing and dyeing wastewater, applied in the field of water pollution treatment, can solve the problems of no progress in advanced treatment research, additional reagent input, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

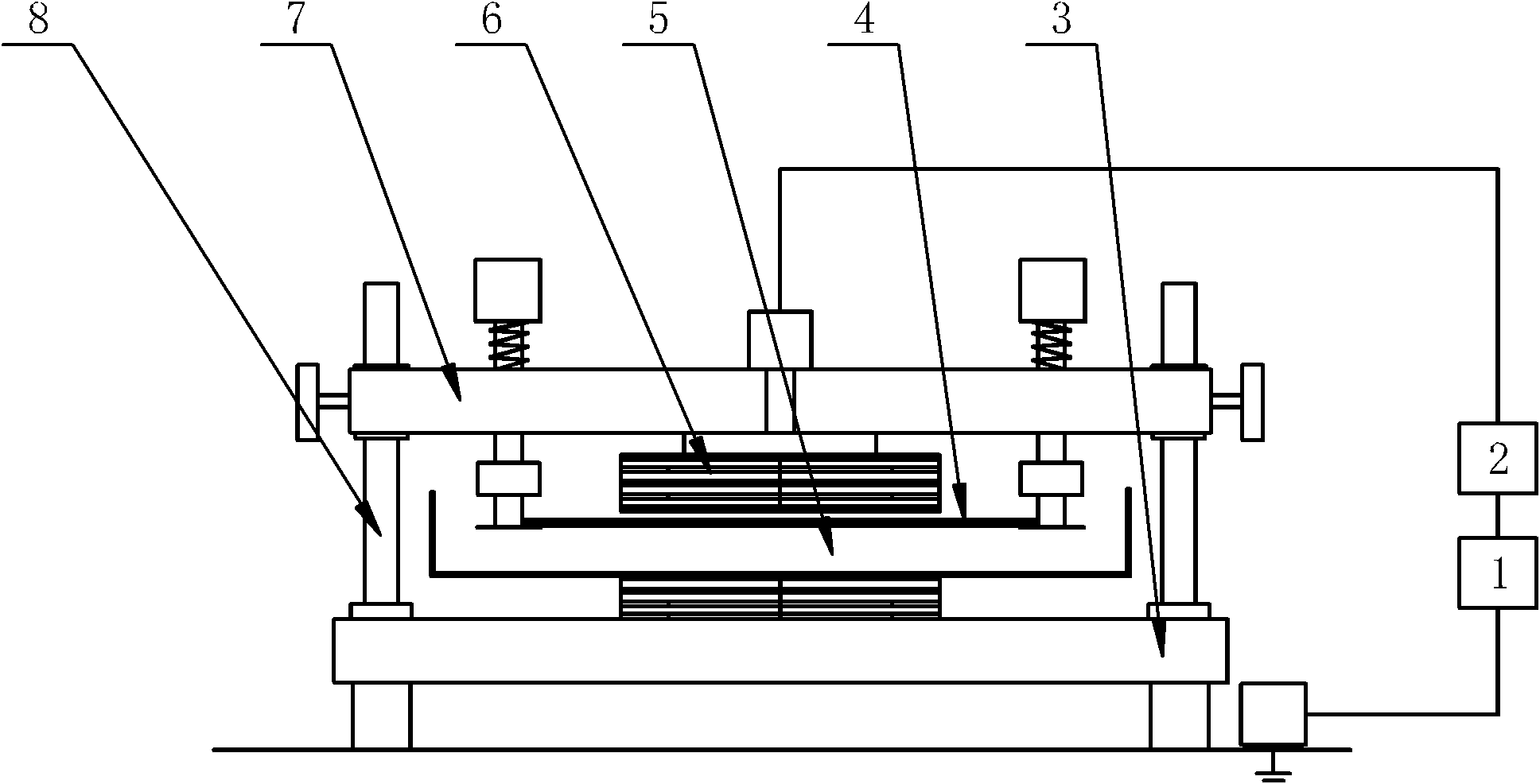

Image

Examples

experiment example 1

[0013] First, draw 10mL of simulated printing and dyeing wastewater (prepared from monoazo dye Acid Bright Yellow) and place it in a lower medium glass dish (wastewater depth is 0.1cm), shake it evenly.

[0014] Then, adjust the discharge parameters of the dielectric barrier discharge low-temperature plasma discharge device as follows: the working gas is air at normal pressure, and the discharge power is 0.175W / cm 2 , the dielectric distance is 5mm; after 2 minutes of discharge, the chromaticity value and COD value of the original solution can be reduced by 97%, and the discharge time of 150 seconds can make the dye solution achieve complete decolorization (absorbance at the maximum wavelength is 0) and complete degradation (COD value is 0). And the output of sludge in the discharge process is 0mg. Among them, the measurement method of chromaticity value is determined by spectrophotometry, the decolorization rate is calculated by formula 1, the measurement method of COD value...

experiment example 2

[0024] First, draw 100mL of simulated printing and dyeing wastewater (prepared directly from disazo dye pink) and place it in a lower medium glass dish (wastewater depth 1cm), shake it evenly.

[0025] Then, adjust the discharge parameters of the dielectric barrier discharge low-temperature plasma discharge device as follows: the working gas is air at normal pressure, and the discharge power is 1.364W / cm 2 , the dielectric distance is 5mm; after 4 minutes of discharge, the chromaticity value and COD value of the original solution can be reduced by 96.73%, and the discharge time of 5 minutes can make the dye solution achieve complete decolorization (absorbance at the maximum wavelength is 0) and complete degradation (COD value is 0). And the output of sludge in the discharge process is 0.01 mg.

experiment example 3

[0027] First, draw 10mL of simulated printing and dyeing wastewater (prepared from trisazo dye monocyclic direct golden camel) and place it in a lower medium glass dish (wastewater depth is 0.1cm), shake it evenly.

[0028] Then, adjust the discharge parameters of the dielectric barrier discharge low-temperature plasma discharge device as follows: the working gas is air at normal pressure, and the discharge power is 1.364W / cm 2 , the dielectric distance is 5mm; the dye solution can be completely decolorized (the absorbance at the maximum wavelength is 0) and completely degraded (the COD value is 0) after 2 minutes of discharge. And the output of sludge in the discharge process is 0mg.

[0029] Experimental examples 1-3 show that dielectric barrier discharge low-temperature plasma can make advanced treatment of printing and dyeing wastewater that has reached the standard in a short period of time, and achieve the purpose of reducing sludge discharge during the advanced treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com