Simple process for treating wastewater containing various dyes

A dye wastewater, simple technology, applied in filtration treatment, sedimentation treatment, multi-stage water treatment and other directions, can solve the problems of secondary pollution, low investment cost, large dosage, etc., to save construction cost and save operating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

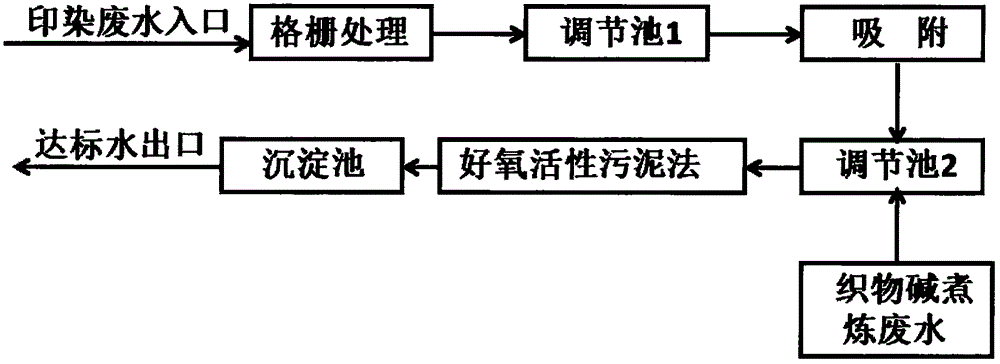

Image

Examples

Embodiment 1

[0011] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, put the dredging sludge into the adsorption pool in advance (the dredging sludge is soaked in hydrochloric acid with a pH of 3-5 for 4 hours to modify), and the mass volume ratio of the dredging sludge to water is 6-10kg / m 3 ;In the adsorption tank, the adsorption time of wastewater and dredging sludge is 5-6 hours, the temperature is natural, and then settle for 5-6 hours; after the adsorption treatment, the chromaticity removal rate of wastewater reaches 98%, and the COD removal rate is 20-35%; The supernatant after sedimentation enters the adjustment tank 2 and mixes with the fabric alkali scouring wastewater until the pH is 6-8, then pumps it into the aeration tank and treats it with the aerobic act...

Embodiment 2

[0013] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, put the dredging sludge in the adsorption pool in advance (the dredging sludge is modified by soaking in hydrochloric acid with a pH of 3-5 for 4 hours), and the mass volume ratio of the dredging sludge to water is 10-15kg / m 3 ;In the adsorption tank, the adsorption time of wastewater and dredging sludge is 5-6 hours, the temperature is natural, and then settle for 5-6 hours; after adsorption treatment, the removal rate of wastewater color reaches 99.5%, and the removal rate of COD is 28-39%; The supernatant after sedimentation enters the adjustment tank 2 and mixes with the fabric alkali scouring wastewater until the pH is 6-8, then pumps it into the aeration tank and treats it with the aerobic activat...

Embodiment 3

[0015] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, put the dredging sludge into the adsorption pool in advance (the dredging sludge is modified by soaking in hydrochloric acid with a pH of 3-5 for 4 hours), and the mass volume ratio of the dredging sludge to water is 6-10kg / m 3 ;In the adsorption tank, the adsorption time of wastewater and dredging sludge is 2-3 hours, the temperature is 35°C (the temperature is maintained by the high-temperature wastewater in the workshop), and then settles for 5-6 hours; after the adsorption treatment, the color removal rate of wastewater reaches 99% , the COD removal rate is 28-35%; the supernatant after sedimentation enters the adjustment tank 2 and mixes with the fabric alkali scouring wastewater until the pH is 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com