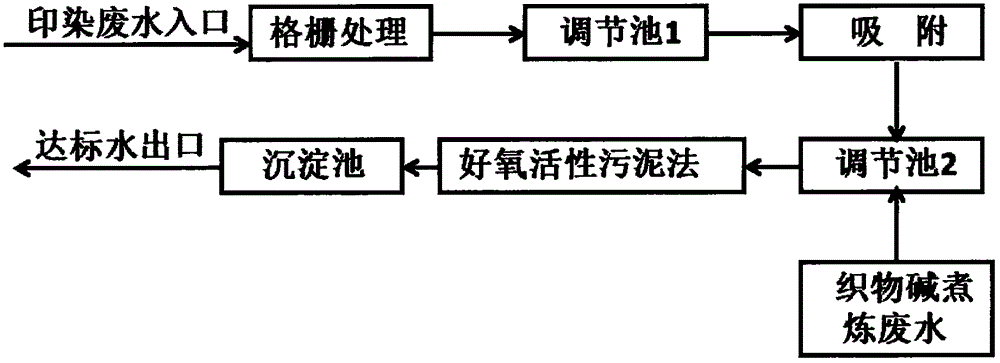

Treatment process for wastewater in dyeing and finishing industry

A technology for industrial wastewater and treatment process, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of secondary pollution, low investment cost, large dosage, etc., to save construction costs , the effect of saving running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, drop in the broken mushroom cultivation waste in advance in the adsorption pond (the particle size of the broken mushroom cultivation waste is between 0.5-2cm, and it is modified in hydrochloric acid with pH 3-5 for 4 hours in advance), the mushroom cultivation waste and The mass volume ratio of water is 8-10kg / m 3 ;In the adsorption tank, the adsorption time of wastewater and mushroom cultivation waste is 5-6 hours, the temperature is natural, and then settle for 1-2 hours; after adsorption treatment, the removal rate of wastewater color reaches 97%, and the removal rate of COD is 20-35%; The supernatant after sedimentation enters the adjustment tank 2 and mixes with the fabric alkali scouring wastewa...

Embodiment 2

[0013] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, and put the broken mushroom cultivation waste into the adsorption pond in advance (the mushroom cultivation waste is soaked in hydrochloric acid with a pH of 3-5 to modify it for 4 hours), and the mass volume ratio of the mushroom cultivation waste to water is 10-15kg / m 3 ;In the adsorption tank, the adsorption time of wastewater and mushroom cultivation waste is 5-6 hours, the temperature is natural, and then settle for 1-2 hours; after adsorption treatment, the removal rate of wastewater color reaches 98%, and the removal rate of COD is 30-38%; The supernatant after sedimentation enters the adjustment tank 2 and mixes with the fabric alkali scouring wastewater until the pH is 6-8, then pumps it into t...

Embodiment 3

[0015] Wastewater containing a variety of disperse dyes (COD 1500-1800mg / L, pH 5-6) is treated with grids to remove large particles and then enters the adjustment pool 1, and the pH of the wastewater is adjusted to 3-5 with industrial hydrochloric acid Enter the adsorption pool, and put the broken mushroom cultivation waste into the adsorption pond in advance (the mushroom cultivation waste is soaked in hydrochloric acid with a pH of 3-5 to modify it for 4 hours), and the mass volume ratio of the mushroom cultivation waste to water is 6-10kg / m 3 The adsorption time of wastewater and mushroom cultivation waste in the adsorption pond is 2-3 hours, the temperature is 35°C (the water temperature in the adsorption pond is maintained by the high-temperature wastewater in the workshop), and then settles for 1-2 hours; after the adsorption treatment, the color of the wastewater The removal rate reaches 98.5%, and the COD removal rate is 25-35%. The supernatant after sedimentation enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com