Method for preparing diisobutyl phthalate

A technology of diisobutyl phthalate and phthalic anhydride, which is applied in the field of synthesizing diisobutyl phthalate, can solve the problems of high sewage treatment operation cost, shortened equipment life cycle, and increased production cost, etc. , achieve the effect of less waste water discharge, easy recycling and application, and reduce waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

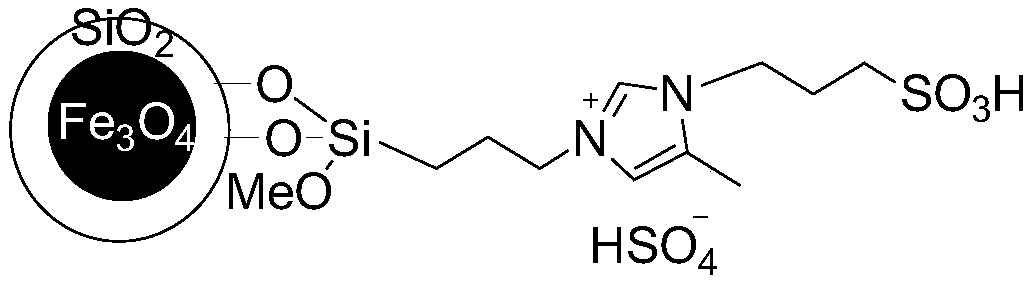

[0044] Example 1, the preparation of the magnetic nanoparticle-loaded acidic ionic liquid as catalyst:

[0045] 1) Obtain SiO2 2 @Fe 3 o 4 magnetic nanoparticles;

[0046] 2), [SO 3 H-pMIM-CPMS][HSO 4 ] acidic ionic liquid;

[0047] 3), magnetic nanoparticles loaded acidic ionic liquid

[0048] In 500ml of anhydrous toluene, add 30.0g of ferric oxide particles wrapped in silicon dioxide (SiO 2 @Fe 3 o 4 magnetic nanoparticles) and 15.0g [SO 3 H-pMIM-CPMS][HSO 4 ] Acidic ionic liquid, refluxed under nitrogen protection for 24h. Collect it with a magnet, wash it thoroughly with isopropyl ether (about 100-200 ml), and dry it under vacuum at 60° C. for 10 h; obtain an acidic ionic liquid loaded with magnetic nanoparticles.

[0049] Its structural formula is as follows:

[0050]

Embodiment 1

[0052] Embodiment 1, the method for preparing dibutylisobutyl phthalate:

[0053] S1. Add 148.1g (1mol) of phthalic anhydride, 275ml (3mol) of isobutanol, and 7.4g of catalyst into a 500ml three-necked flask. Heat (approximately 120-150° C.) for reflux dehydration, react for 4 hours, and cool the reaction solution to room temperature.

[0054] S2. Filter the reaction liquid after cooling S1 to room temperature, add 1.5 g of calcium oxide to the obtained filtrate I, and stir at room temperature for 1 h. Filtrate to obtain filtrate II and filter cake respectively, and the filter cake is washed with a small amount (about 15 ml) of isobutanol.

[0055] The washing liquid and the filtrate II were combined and dealcoholized under reduced pressure (heating under a pressure of less than 10 kPa to achieve isobutanol removal) to obtain 276.9 g of diisobutyl phthalate. The purity by gas phase analysis was 99.9%, and the yield was 99.5%.

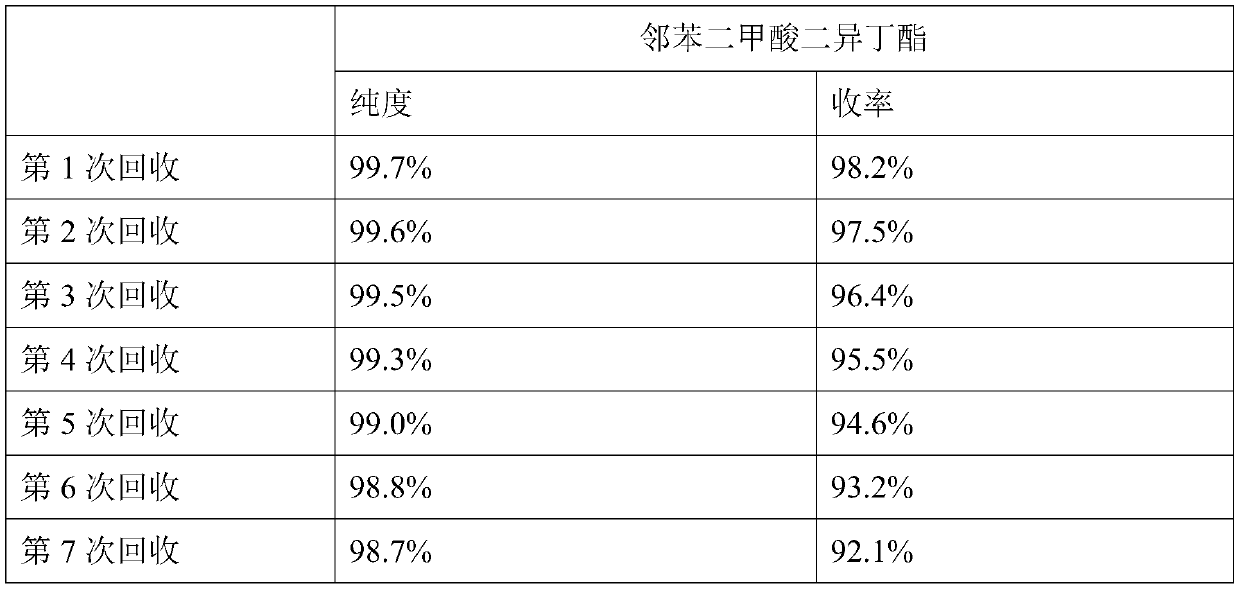

[0056] The filter cake obtained by filtration ...

Embodiment 2

[0057] Embodiment 2, the method for preparing dibutylisobutyl phthalate:

[0058] S1. Add 148.1 g of phthalic anhydride, 184 ml (2 mol) of isobutanol, and 7.4 g of catalyst into a 500 ml three-necked flask. Heat (approximately 120-150° C.) for reflux dehydration, react for 4 hours, and cool the reaction solution to room temperature.

[0059] S2, is equal to S2 of embodiment 1.

[0060] 267.7 g of diisobutyl phthalate was obtained, the gas phase analysis purity was 99.4%, and the yield was 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com