A production process and device for direct edible syrup

A production process and syrup technology, applied in sugar production, sugar juice production, sucrose production, etc., can solve the problems of high energy consumption, low filtration precision, and many equipments, and achieve high yield, high desalination rate, color The effect of low value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

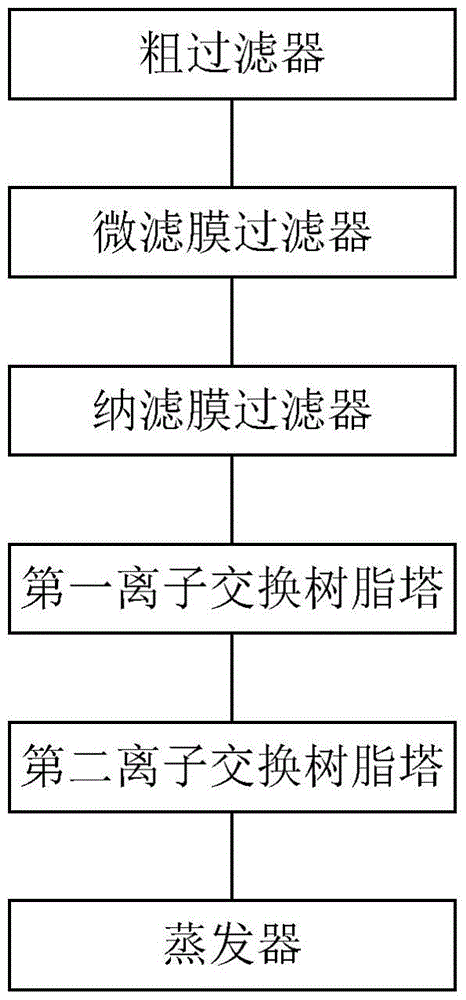

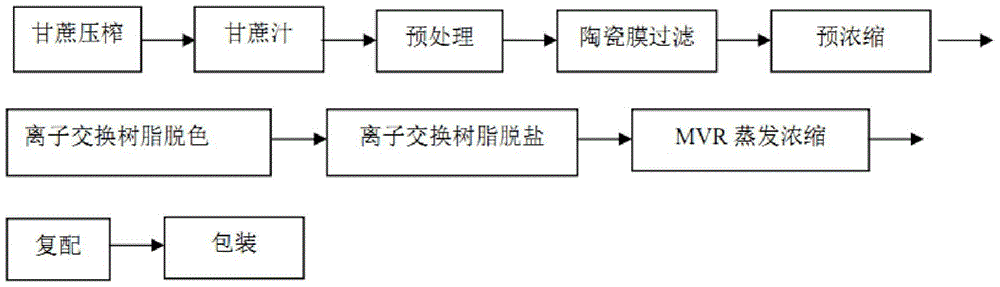

[0031] Such as figure 1 Shown, a kind of novel process of directly edible syrup of the present invention comprises the following steps:

[0032] A. Juicing: squeeze the sugarcane through a juice extractor to obtain sugarcane juice;

[0033] B, pretreatment: the sugarcane juice obtained in the step A is pretreated by a sieve to remove larger bagasse, and the aperture of the sieve is 100 orders;

[0034] C, microfiltration membrane filtration: the sugarcane juice collected in step B is microfiltered through 50 nm, 200 nm, and 500 nm ceramic membranes respectively, the temperature of filtration is 20 ° C, and the filtration pressure is 0.5 Mpa to obtain the sucrose juice clear liquid, The concentration of sucrose is 12%;

[0035] D. Membrane concentration: the sugarcane juice clear liquid enters the nanofiltration membrane device for concentration. The material of the nanofiltration membrane is polyethersulfone, the molecular weight cut-off is 100Da, the nanofiltration pressure...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of novel process of directly edible syrup of the present invention comprises the following steps:

[0046] A. Juicing: squeeze the sugarcane through a juice extractor to obtain sugarcane juice;

[0047] B, pretreatment: the sugarcane juice obtained in the step A is pretreated by a sieve to remove larger bagasse, and the aperture of the sieve is 100 orders;

[0048] C. Microfiltration membrane filtration: the sugarcane juice collected in step B is microfiltered through a 200 nm ceramic membrane, the filtration temperature is 20°C, 80°C, 90°C, and the filtration pressure is 0.1MPa to obtain the sucrose juice serum , the sucrose concentration is 15%;

[0049] D. Membrane concentration: the sugarcane juice clear liquid enters the nanofiltration membrane device for concentration. The material of the nanofiltration membrane is polyethersulfone, the molecular weight cut-off is 500Da, the nanofiltration pressure is 1.0Mpa, and the volume of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com