Process for advanced treatment of antibiotic waste water

A technology for advanced treatment of antibiotic wastewater, applied in multi-stage water treatment, water/sewage treatment, natural water body treatment, etc., can solve the unsolved problems of difficult biochemical substance degradation in wastewater, difficulty in reaching discharge standards for effluent, and poor comprehensive biodegradability and other problems, to achieve the effect of small amount of sludge, short process route, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

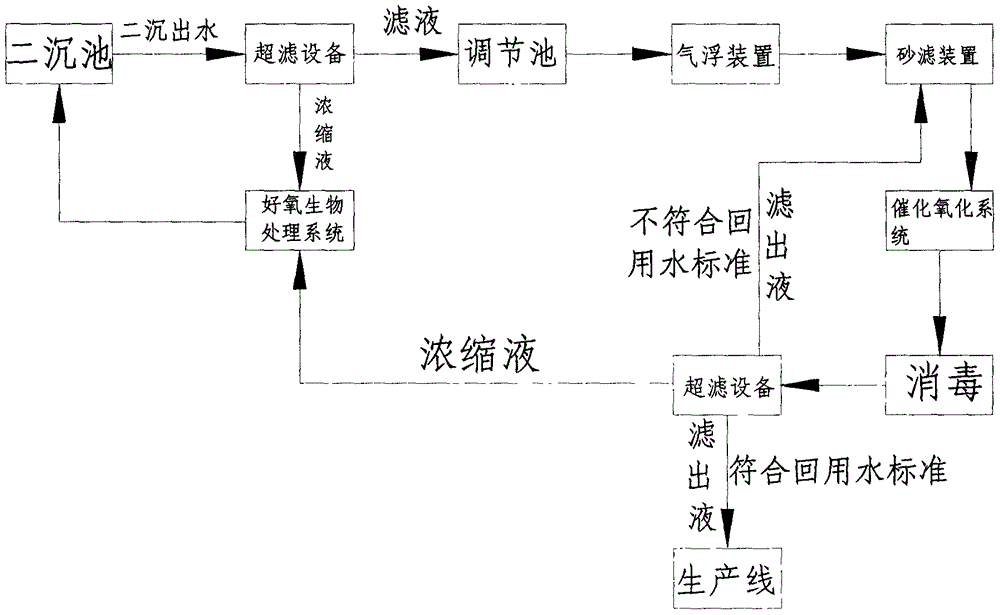

[0020] like figure 1 Shown, a kind of advanced treatment process of antibiotic waste water, this process is to do further treatment to the waste water that the secondary settling tank handles in the process of antibiotic waste water treatment, and this process comprises the following steps: first send the waste water that the secondary settling tank handles into The ultrafiltration equipment performs ultrafiltration treatment to filter out the macromolecular particulate matter in the wastewater, and then obtain the concentrate and filtrate; then send the concentrate to the aerobic biological treatment system for degradation treatment, and degrade the aerobic biological treatment system The final concentrated solution is sent to the secondary sedimentation tank, and the filtrate is further processed according to the following steps: Step 1, adjustment: the above-mentioned filtrate obtained is sent to the adjustment tank, and the water quality, water quantity, and pH of the filtr...

Embodiment 2

[0023] like figure 1 Shown, a kind of advanced treatment process of antibiotic waste water, this process is to do further treatment to the waste water that the secondary settling tank handles in the process of antibiotic waste water treatment, and this process comprises the following steps: first send the waste water that the secondary settling tank handles into The ultrafiltration equipment performs ultrafiltration treatment to filter out the macromolecular particulate matter in the wastewater, and then obtain the concentrate and filtrate; then send the concentrate to the aerobic biological treatment system for degradation treatment, and degrade the aerobic biological treatment system The final concentrated solution is sent to the secondary sedimentation tank, and the filtrate is further processed according to the following steps: Step 1, adjustment: the above-mentioned filtrate obtained is sent to the adjustment tank, and the water quality, water quantity, and pH of the filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com