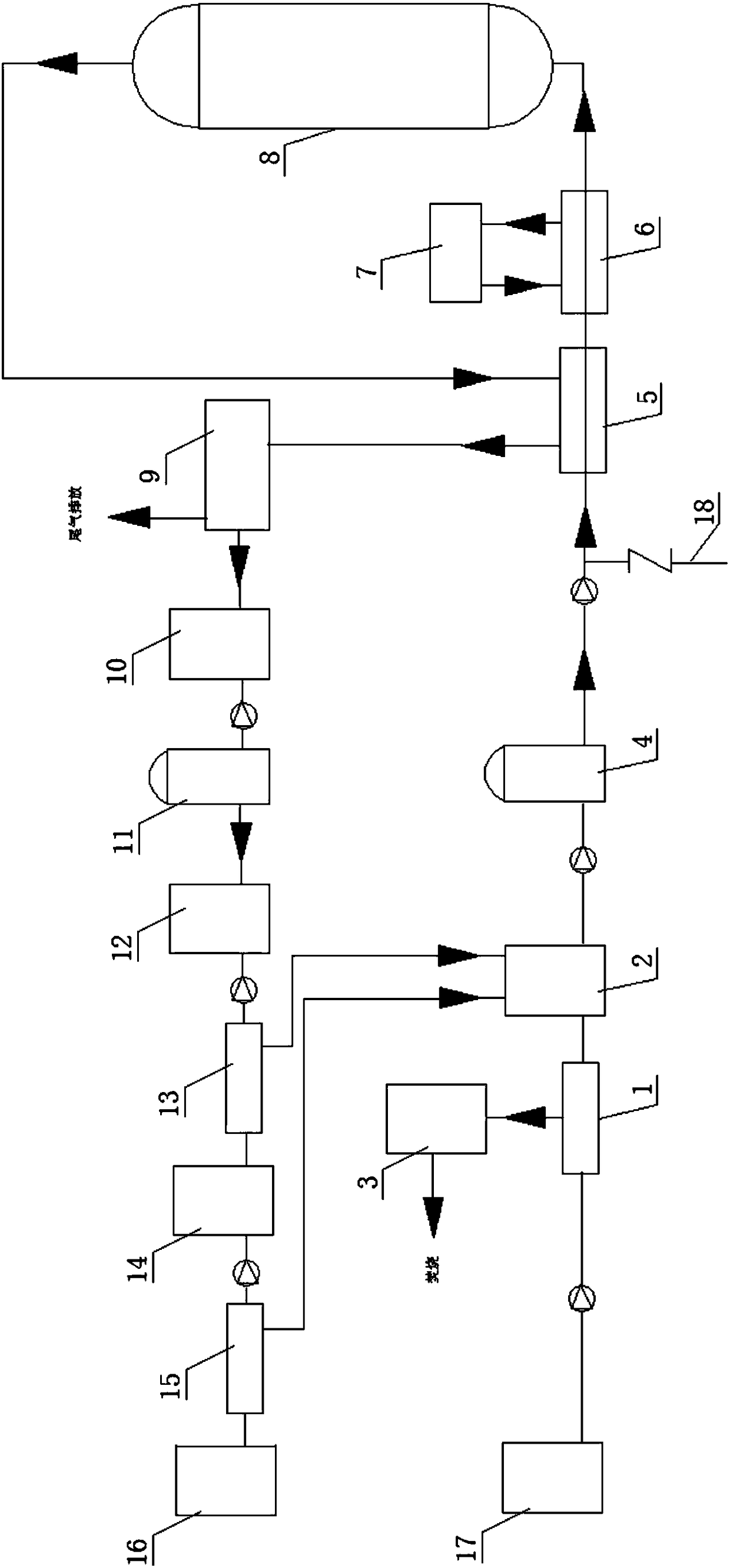

Method and apparatus for treating high-concentration emulsion wastewater

A treatment method and technology of treatment devices, which are applied in the directions of multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of paralysis of biochemical systems, low oxygen content, affecting treatment process, etc., and reduce COD. and color value, strong impact resistance, high color value removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Emulsion wastewater (COD 200g / L, chroma 800, salt content 0.5%, oil content 5600mg / L) first enters the inorganic ceramic membrane filtration device, the pore size of the ceramic membrane is 50nm, and the oil-water separation is carried out under the operating pressure of 0.3MPa to obtain the inorganic membrane Concentrates and serums. The oil content of the inorganic membrane concentrate is 60g / L, and it is directly incinerated; the clear liquid (COD 31200mg / L, chroma 790, salt content 0.5%, oil content 300mg / L) passes through a heat exchanger and a heat transfer oil heat exchanger After heating in sequence, the temperature reaches 230°C, and it is continuously passed into the catalytic reaction tower, and CuO / Al is filled in the catalytic reaction tower. 2 o 3 Catalyst, the CuO loading capacity is 4.46 (wt)%, with catalyst effective component CuO, the consumption of catalyst is 300g / ton to treat waste water), and constantly feed pure oxygen in the system (passage is 3...

Embodiment 2

[0053] The emulsion wastewater (COD 250g / L, chroma 900, salt content 0.6%, oil content 6000mg / L) first enters the inorganic ceramic membrane filtration device, the ceramic membrane pore size is 50nm, and the oil-water separation is carried out under the operating pressure of 0.3MPa to obtain the inorganic membrane Concentrates and serums. The oil content of the inorganic membrane concentrate is 65g / L, and it is directly incinerated; the clear liquid (COD 25200mg / L, chroma 850, salt content 0.6%, oil content 330mg / L) passes through a heat exchanger and a heat transfer oil heat exchanger After heating in sequence, the temperature reaches 240°C, and it is continuously passed into the catalytic reaction tower, and CuO-MnO / Al is filled in the catalytic reaction tower. 2 o 3 Catalyst (CuO loading 3.53 (wt) %, MnO loading 2.34 (wt) %, based on the total amount of catalyst active components CuO, MnO, the consumption of catalyst is 300g / ton of waste water to be treated), and constantl...

Embodiment 3

[0055] Emulsion wastewater (COD 300g / L, chroma 700, salt content 0.4%, oil content 4800mg / L) first enters the inorganic ceramic membrane filtration device, the ceramic membrane pore size is 50nm, and the oil-water separation is carried out under the operating pressure of 0.3MPa to obtain the inorganic membrane Concentrates and serums. The oil content of the inorganic membrane concentrate is 70g / L, which is directly incinerated; the clear liquid (COD 35000mg / L, chroma 680, salt content 0.4%, oil content 200mg / L) passes through a heat exchanger and a heat transfer oil heat exchanger After heating in sequence, the temperature reaches 245°C, and it is continuously passed into the catalytic reaction tower, and CuSO is loaded into the catalytic reaction tower at the rate of 300g / ton of waste water to be treated. 4 Ionic state catalyst, and continuously feed pure oxygen into the system (the amount of feed is 3m 3 / h), the residence time of wastewater in the catalytic oxidation tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com