Method for regenerating sugar making decolorized and decalcified resin and method for recycling regeneration waste liquid

A technology for decolorizing resin and resin regeneration, which is applied to the cleaning of sugar juice or syrup of ion exchange resins, the regeneration of resin and the reuse of waste liquid, which can solve the problems of refining syrup in the secondary cleaning process, environmental pollution of regeneration waste liquid, The effect of syrup is limited and other problems, to achieve the effect of improving syrup quality, reducing scaling, and saving evaporation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

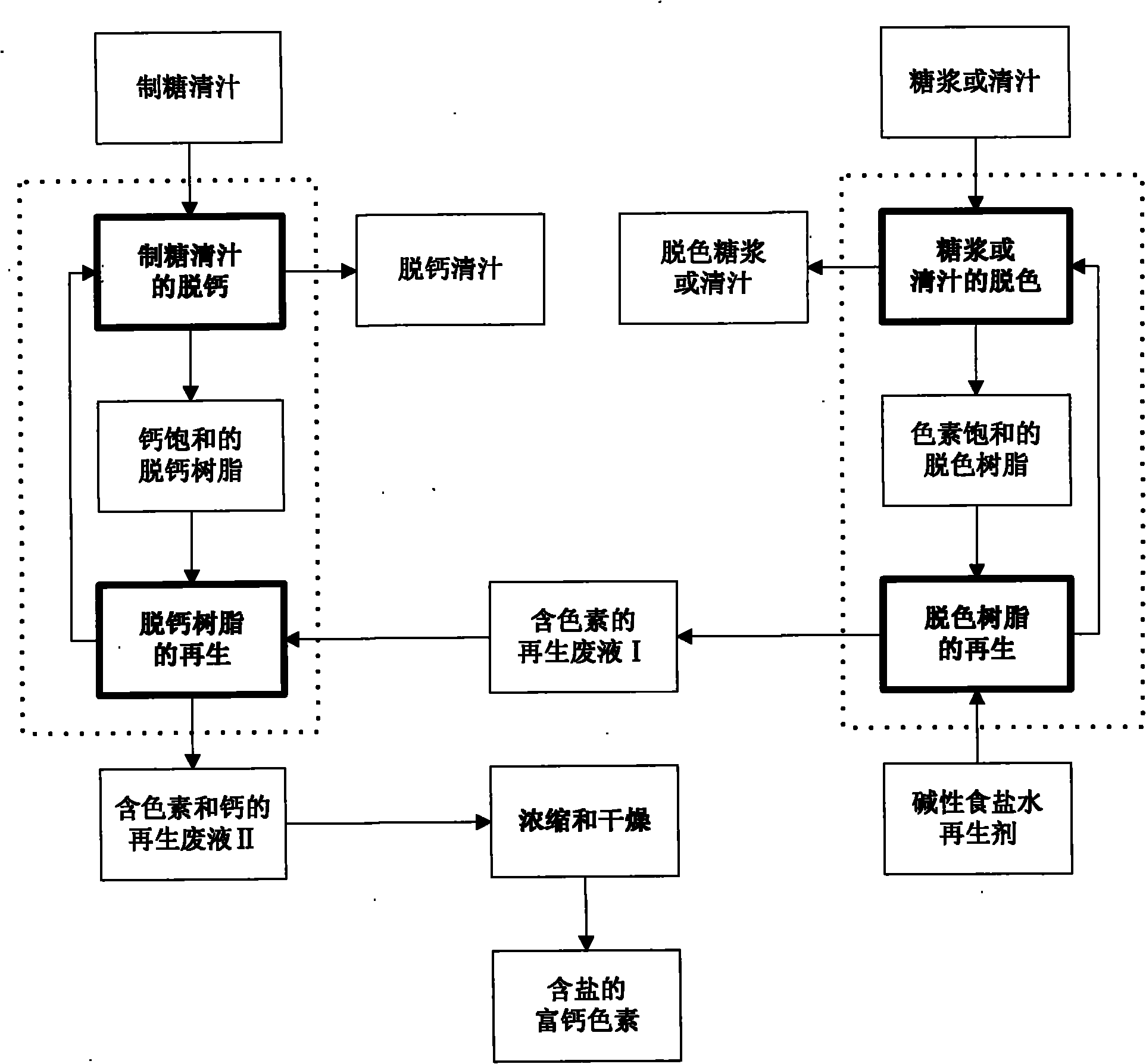

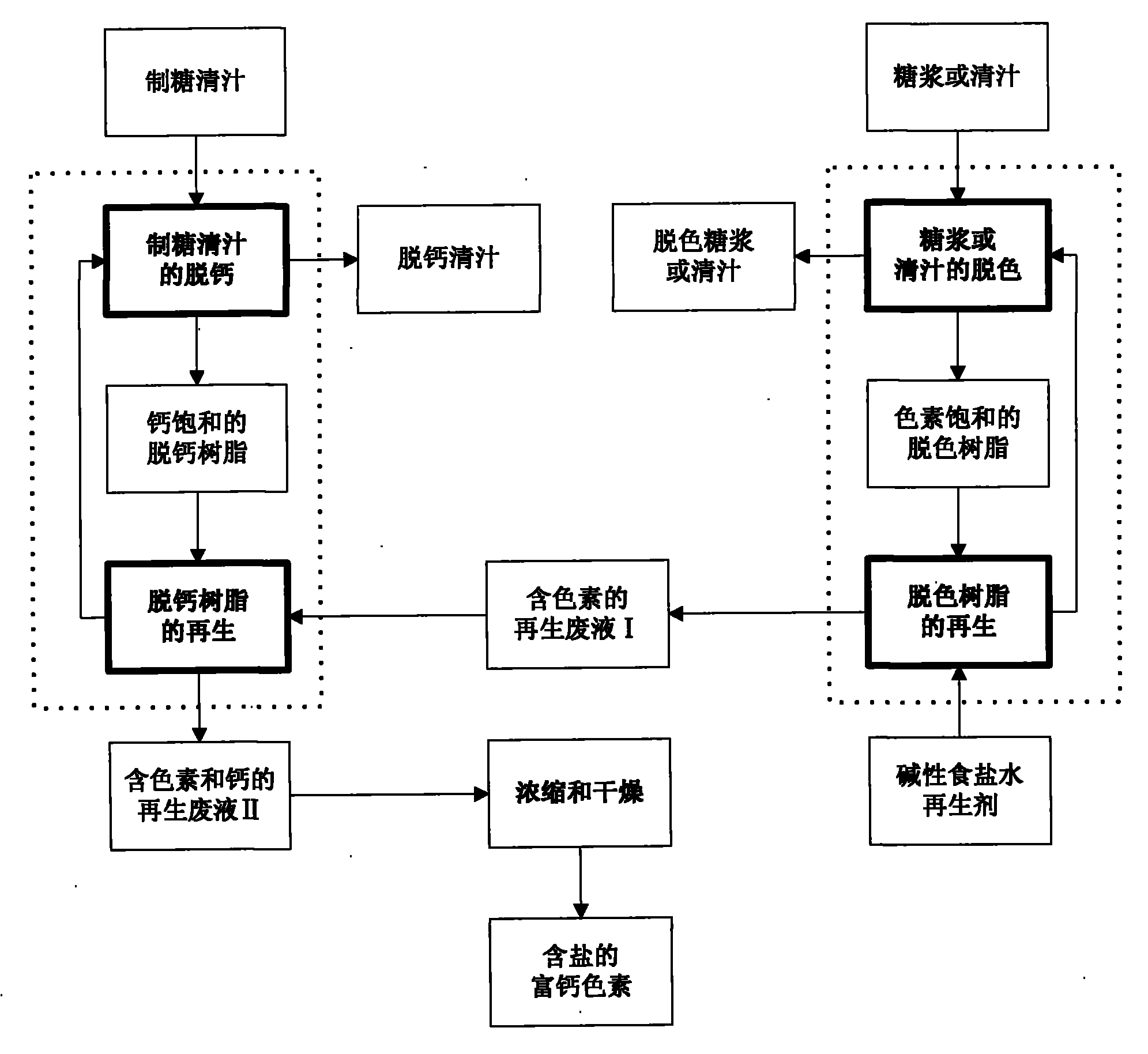

[0030] Such as figure 1 Shown, the regeneration of sugar decolorization and decalcification resin and the reuse method of regeneration waste liquid comprise the following steps: (1) decolorization of syrup or sugar juice; (2) regeneration of decolorization resin; (3) decolorization of sugar clear juice calcium; (4) regeneration of decalcified resin; (5) preparation of calcium-rich pigment by concentration and drying method. Specific steps are as follows:

[0031] (1) Decolorization of syrup: Fill 25L strong base anion exchange resin D201×7 in the ion exchange column (Φ0.15m×2.00m), and the resin uses 2BV mass fraction of 4% NaOH solution to circulate through the resin at a flow rate of 2BV / h bed treatment (i.e. circulation treatment, the same below) for 1 hour, backwash the resin bed with demineralized water until the effluent pH value is 8.0 to 9.0, then use 2BV volume fraction of 4% HCI solution to circulate for 1 hour at 2BV / h, and then wash with demineralized water until ...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] Change the syrup in step (1) to beet sugar factory second-clear juice, its hammer, temperature and processing capacity are 15°Bx, 70°C and 3250L (i.e. 130BV) respectively, the injection flow rate is 10BV / h, and the second-clear juice is decolorized Later used for sulfur bleaching. At this time, the decolorization rate of the second clear juice is greater than 75.0%.

[0040] Adjust the alkaline saline regenerant in step (2) to a mixed solution of 80g / L NaCl and 1g / L NaOH, and the temperature and dosage of the regenerant are 60°C and 750L, ie 30BV, respectively. At this time, the regeneration rate of the decolorized resin was 98.7%.

[0041] Ca is used in step (3) 2+ The content is 300mg / L (calculated as CaO) of beet sugar factory second clear juice, the processing capacity is 120BV (3000L), the temperature is 85°C, and the flow rate is 12BV / h. At this time, the decalcification rate of Erqing Juice ...

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is:

[0047] Change the syrup in step (1) into the evaporated syrup of the sulfite method sugarcane sugar factory, the hammer, temperature and processing capacity after dilution are 50°Bx, 80°C and 1000L (ie 40BV) respectively, and the feed flow rate is 3BV / h, the syrup is decolorized and used for evaporating and boiling sugar. At this time, the decolorization rate of syrup is greater than 81.0%.

[0048] Adjust the alkaline salt water regeneration agent in step (2) to a mixed solution of 96g / L NaCl and 3g / L NaOH, and the temperature and dosage of the regeneration agent are respectively 75°C and 600L or 24BV. At this time, the regeneration rate of the decolorized resin was 97.8%.

[0049] Ca is used in step (3) 2+ The content is 400mg / L (calculated as CaO) in the clear juice of the sulfitic cane sugar factory, the processing capacity is 90BV (2250L), the temperature is 80°C, and the flow rate is 10BV / h. At thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com