Purification method for HFCS (high fructose corn syrup) in fructose production process

A fructose syrup and production process technology, which is applied in fructose production, sugar production, sucrose production, etc., can solve the technical difficulties of fructose separation, crystallization and drying, the yield of products at one time is less than 40%, and the production equipment does not match To achieve the effect of shortening the stay and waiting time, improving production efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

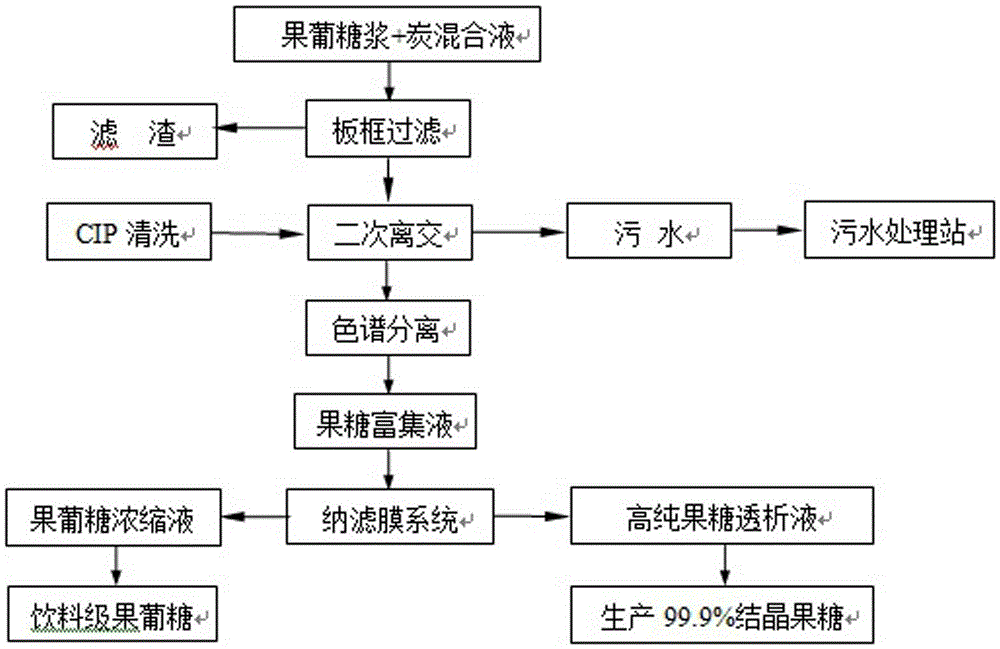

Method used

Image

Examples

Embodiment 1

[0072] An embodiment of the present invention is a method for producing pharmaceutical anhydrous crystalline fructose with sugarcane as a raw material. The process includes the following steps in sequence: pressing and concentrating sugarcane juice, preparing fructose syrup solution, refining fructose syrup, separating refined fructose syrup, Fructose crystallization and glucose recovery.

[0073] The specific process steps are:

[0074] (1) Squeeze and concentrate sugarcane juice: Squeeze sugarcane and use sulfur dioxide or carbonic acid cleaning process and three-effect evaporation to concentrate to obtain concentrated cane juice with a Brix of 50Bx;

[0075] (2) Preparation of fructose syrup solution: put the concentrated cane juice into the reaction kettle, and adjust the reaction pH value to 2.5 with 10% hydrochloric acid HCl at a reaction temperature of 105°C, and the reaction time is 60 minutes; add liquid alkali NaOH after complete hydrolysis Neutralize to pH = 6.0; o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com