Prepn process of Sn-Cu alloy material for negative pole of lithium ion cell

A lithium-ion battery, tin-copper alloy technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as difficulty in large-scale production, and achieve the effects of low cost and improved charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

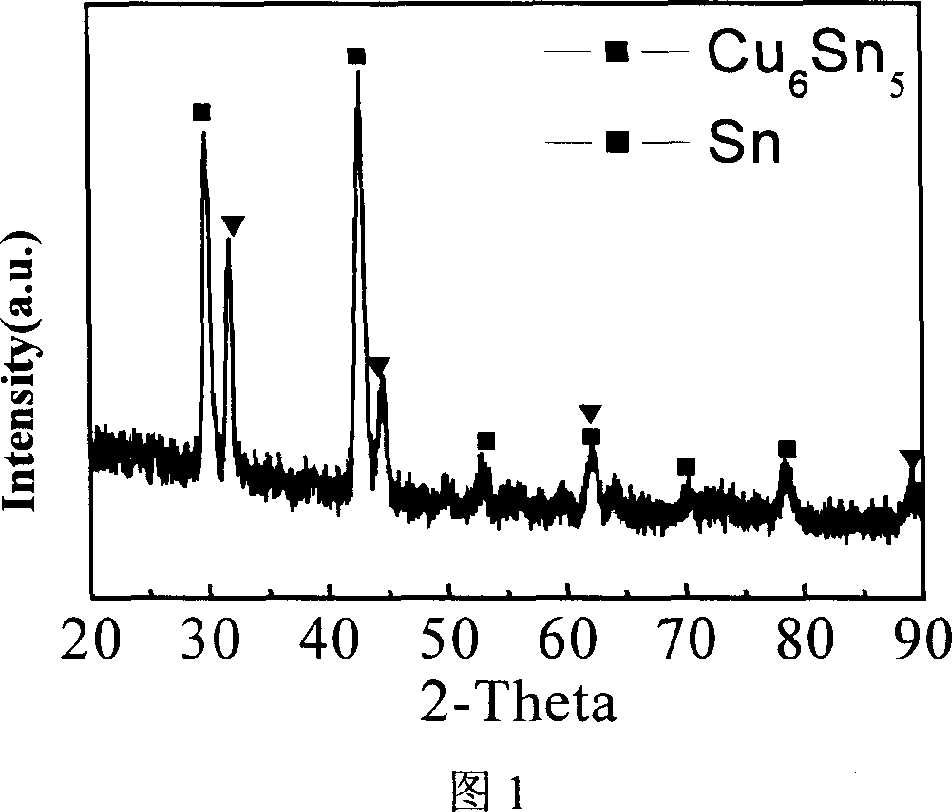

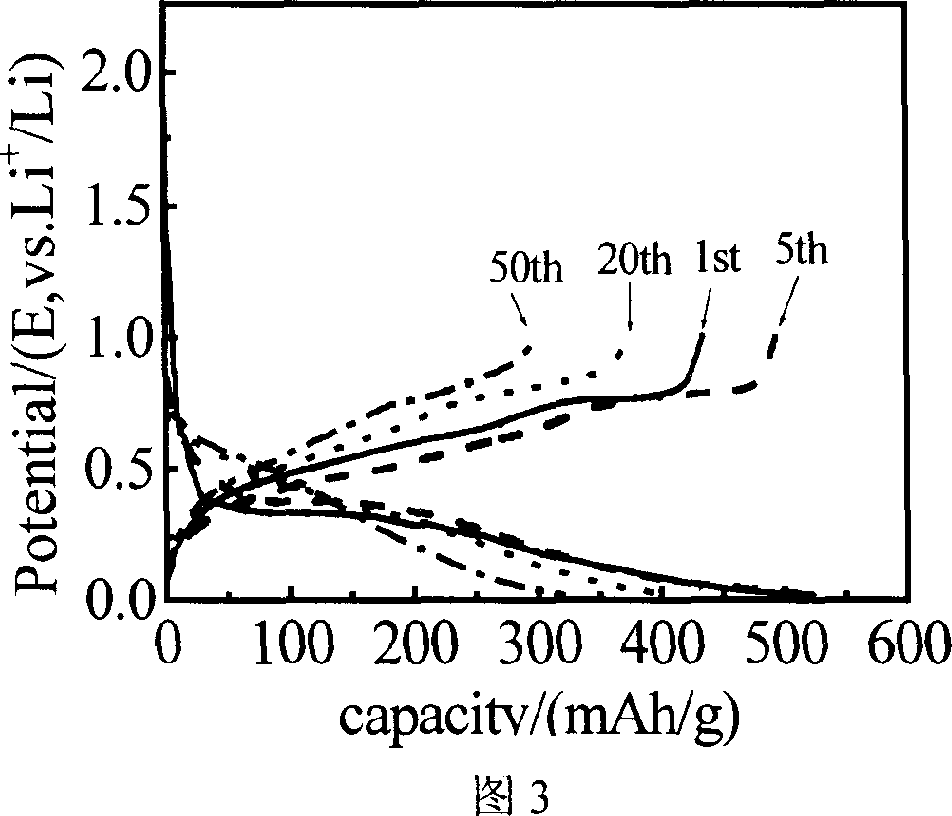

[0022] Potassium pyrophosphate is dissolved in deionized water, under the situation of stirring, add stannous chloride and cupric sulfate respectively, obtain mixed solution, the concentration of potassium pyrophosphate is 100g / L, and the concentration of stannous chloride is 10g / L, The concentration of copper sulfate is 5g / L. Add additives in the mixed solution, the additives are epichlorohydrin, triethanolamine, formaldehyde and gelatin, calculated according to the total volume of the mixed solution, the content of the additive in the mixed solution is 0.7g / L of epichlorohydrin, 0.8g of triethanolamine / L, formaldehyde 0.5g / L, gelatin 0.03g / L to obtain electroplating solution. at 0.7A / dm 2 Under the conditions of current density and stirring, the copper sheet is used as the base and electroplated in the electroplating solution for 5 minutes to form a silver-white bright plating layer, that is, a tin-copper alloy is obtained.

Embodiment 2

[0024] Potassium pyrophosphate is dissolved in deionized water, under the situation of stirring, add tin protochloride and cupric sulfate respectively, obtain mixed solution, the concentration of potassium pyrophosphate is 200g / L, and the concentration of stannous chloride is 15g / L, The concentration of copper sulfate is 6g / L. Add additives in the mixed solution, the additives are epichlorohydrin, triethanolamine, formaldehyde and gelatin, calculated according to the total volume of the mixed solution, the content of the additive in the mixed solution is epichlorohydrin 1g / L, triethanolamine 0.7g / L L, formaldehyde 0.7g / L, gelatin 0.05g / L to obtain electroplating solution. at 0.8A / dm 2 Under the conditions of current density and stirring, the copper sheet is used as the substrate and electroplated in the electroplating solution for 7 minutes to form a silver-white bright plating layer, that is, a tin-copper alloy is obtained.

Embodiment 3

[0026] Potassium pyrophosphate is dissolved in distilled water, under the situation of stirring, add stannous chloride and cupric sulfate respectively, obtain mixed solution, the concentration of potassium pyrophosphate is 300g / L, the concentration of stannous chloride is 25g / L, sulfuric acid The concentration of copper is 3g / L. Add additives in the mixed solution, the additives are epichlorohydrin, triethanolamine, formaldehyde and gelatin, calculated according to the total volume of the mixed solution, the content of the additive in the mixed solution is 0.8g / L of epichlorohydrin, 0.5g of triethanolamine / L, formaldehyde 1g / L, gelatin 0.1g / L, to obtain electroplating solution. at 0.5A / dm 2 Under the conditions of current density and stirring, the copper sheet is used as the substrate and electroplated in the electroplating solution for 1 min to form a silver-white bright coating, that is, a tin-copper alloy is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com