Ion-doped spherical Li4Ti5O12/C lithium ion battery anode material and preparation method thereof

A lithium-ion battery, ion doping technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of poor conductivity, low packing density, difficult to high cycle specific capacity cycle capacity retention rate, etc., to improve the conductivity, The effect of high packing density and improved charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

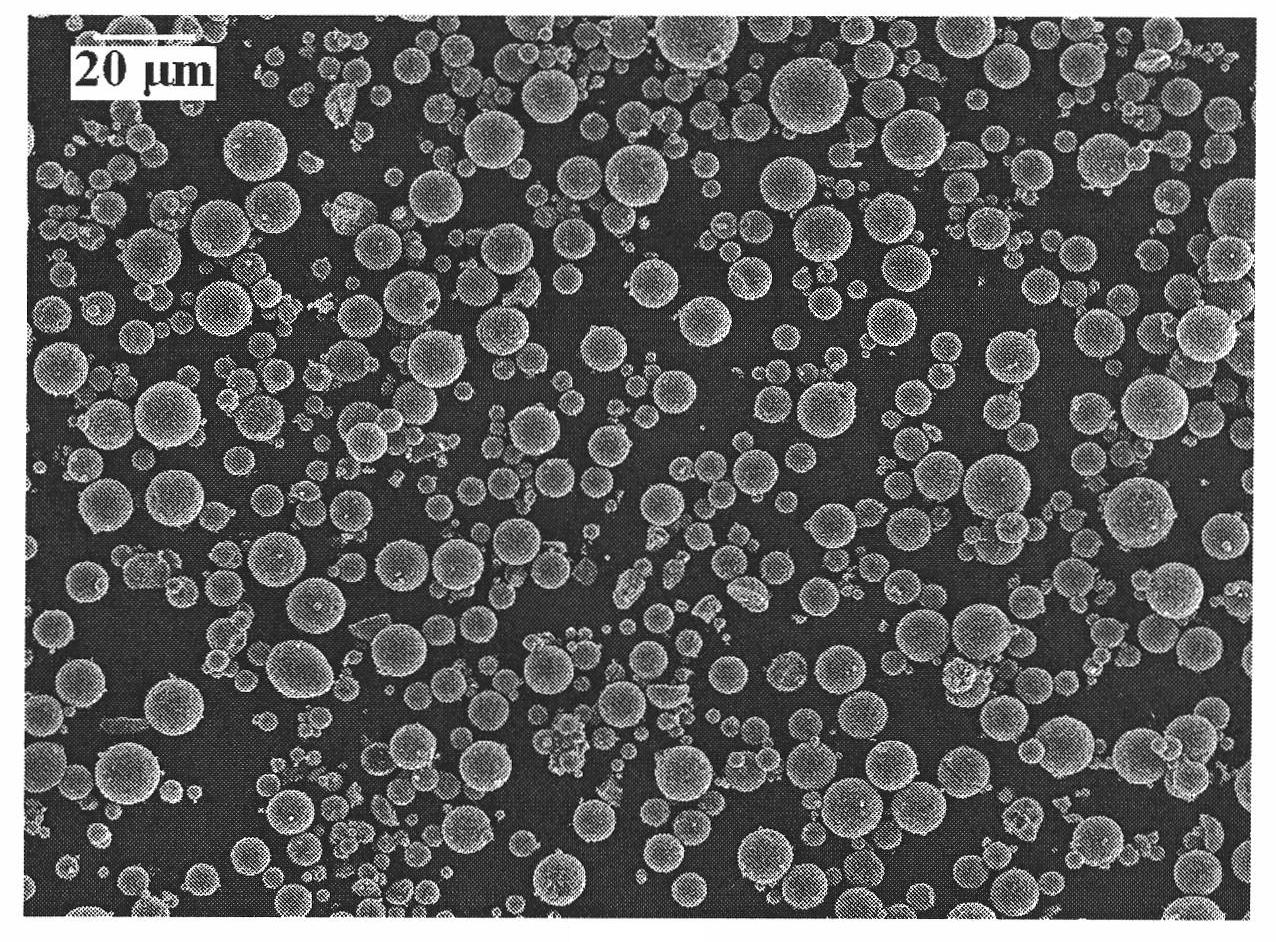

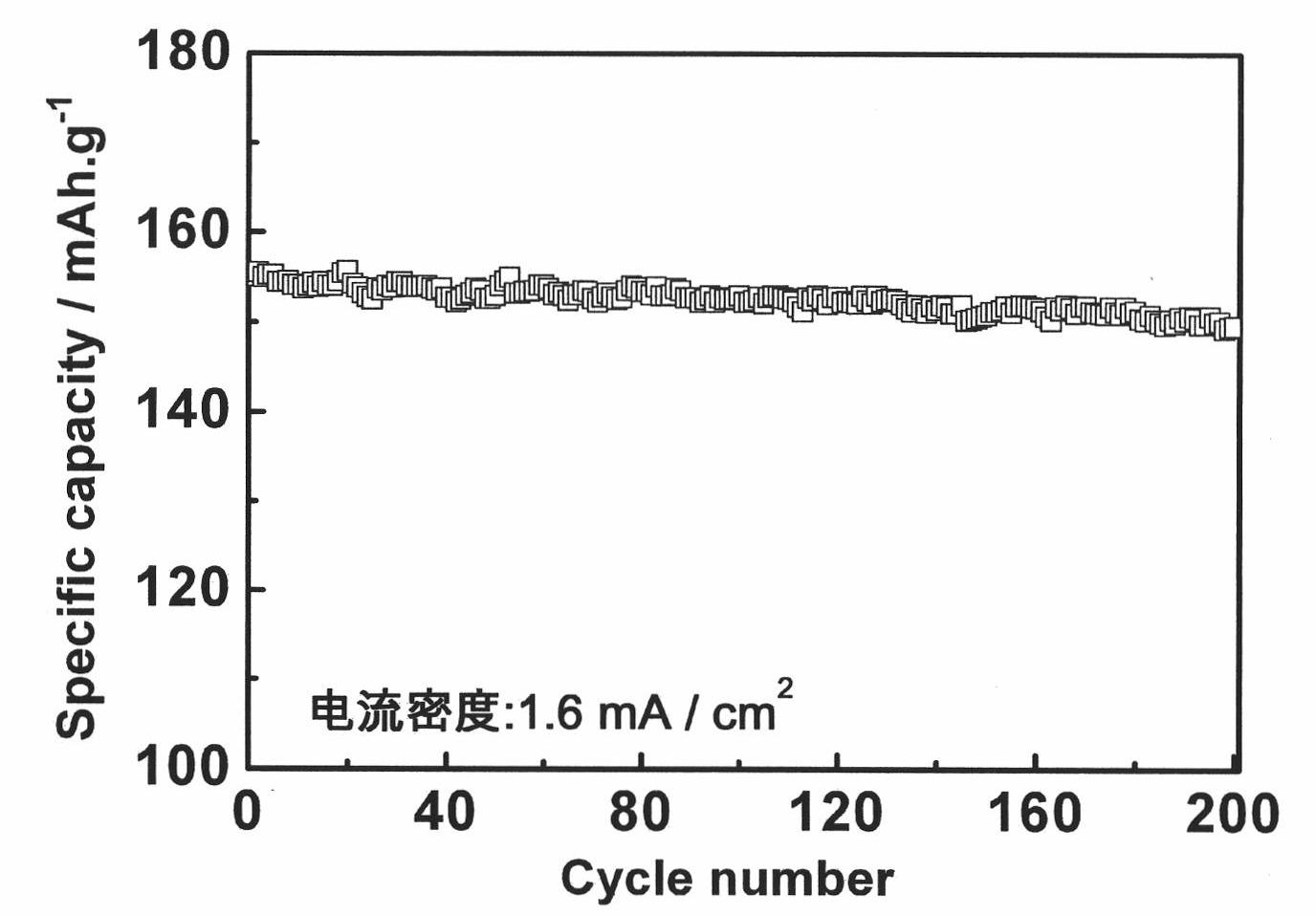

Embodiment 1

[0016] Weigh TiCl 4 Put it in a beaker, add deionized water, and hydrolyze to obtain 2mol / L TiOCl 2 Solution; then weigh LaCl with a molar ratio of La / Ti=1∶100 3 , Dissolved in the above TiOCl 2 In the solution, a homogeneous mixed solution is obtained. Prepare an aqueous ammonia solution with a concentration of 2mol / L. Under stirring, slowly add the aqueous ammonia solution to the above mixed solution until the pH value of the solution reaches 10, stop adding the alkaline solution, centrifuge, and wash to obtain uniform doped ions. La’s hydrated titanium oxide sol precursor; then weigh Li at the ratio Li:Ti=4:5 2 CO 3 , Press and finally generated Li 4 Ti 5 O 12 (Calculated on the basis of the added titanium) Weigh the sucrose with a mass percentage of 20% by weight (because the specific amount of titanium is not indicated in the previous expression, the specific mass of sucrose cannot be calculated here), and the sucrose is evenly dispersed by ball milling In the sol; the obta...

Embodiment 2

[0019] Weigh TiOSO 4 Put it in a beaker, add deionized water, and dissolve to prepare 5mol / L TiOSO 4 Solution; then weigh YCl with a molar ratio of Y / Ti=0.1∶100 3 , Dissolved in the above TiOSO 4 In the solution, a homogeneous mixed solution is obtained. Prepare a NaOH solution with a concentration of 10mol / L. Under stirring, slowly add the NaOH solution to the above mixed solution until the pH value of the solution reaches 10, stop adding the alkali solution, centrifuge, and wash to obtain uniform doped ions. Y hydrated titanium oxide sol precursor; then weigh LiNO at the ratio of Li:Ti=4.05:5 3 , Press and finally generated Li 4 Ti 5 O 12 (Calculated on the basis of the added titanium) Weigh glucose with a mass percentage of 30wt%, and disperse it evenly in the sol by ball milling; the resulting mixed liquid is dried with an airflow spray dryer, using a co-current drying method, and an atomizing device Adopt a dual-flow nozzle, feed with a peristaltic pump at a speed of 10-20m...

Embodiment 3

[0022] Weigh TiCl 4 Put it in a beaker, add deionized water, and hydrolyze to produce 0.1mol / L TiOCl 2 Solution; then weigh MnCl with a molar ratio of Mn / Ti=3∶100 2 Or MnSO 4 , Dissolved in the above TiOCl 2 In the solution, a homogeneous mixed solution is obtained. Prepare a KOH solution with a concentration of 0.1 mol / L. Under stirring conditions, slowly add the KOH solution to the above mixed solution until the pH value of the solution reaches 10, stop adding the alkali solution, centrifuge, and get a uniform doped content after washing The precursor of hydrated titanium oxide sol of ion Mn; then weigh LiOH·H at the ratio of Li:Ti=3.95:5 2 O. Press and finally generated Li 4 Ti 5 O 12 (Calculated based on the added titanium) Weigh the phenolic resin with a mass percentage of 5wt%, and disperse it in the sol uniformly by ball milling; the resulting mixed liquid is dried with an airflow spray dryer, using a co-current drying method, and atomized The device adopts a dual-flow no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com