Agent for forming electrode protection film

An electrode protective film and electrode technology, applied in battery electrodes, hybrid capacitor electrodes, batteries, etc., can solve the problems of battery swelling, decrease in charge-discharge cycle characteristics, etc., to improve long-term durability, excellent long-term stability, and improve charge and discharge. Effect of cycle performance and high temperature storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0120] Hereinafter, although an Example demonstrates this invention further, this invention is not limited to these Examples. Hereinafter, unless otherwise specified, % means % by weight, and part means parts by weight.

[0121] Electrode protective film forming agent (D)

[0122] The number average molecular weight of compound (C-15) was measured using GPC under the following conditions.

[0123] Device (one example): HLC-8120 manufactured by Tosoh Co., Ltd.

[0124] String (one example): TSK GEL GMH6, two pieces, [manufactured by Tosoh Co., Ltd.]

[0125] Measuring temperature: 40°C

[0126] Sample solution: 0.25% by weight THF solution

[0127] Solution injection volume: 100μl

[0128] Detection device: Refractive index detector

[0129] Reference material: manufactured by Tosoh Co., Ltd., standard polystyrene (TSK standard POLY STYRENE), 5 points (Mw 500 1050 2800 5970 9100)

manufacture example 1

[0131] Synthesis of 1-hydroxymethyl-4-(1-propenyloxymethyl)cyclohexane:

[0132] 9.86 parts of 1,4-cyclohexanedimethanol [manufactured by Tokyo Chemical Industry Co., Ltd.] and allyl chloride [manufactured by Tokyo Chemical Industry Co., Ltd.] were added to a flask equipped with a stirrer, a thermometer, and a cooling tube. After stirring 5.76 parts, 6.00 parts of sodium hydroxide, and 100 parts of toluene to dissolve the above-mentioned components uniformly, it stirred at room temperature for 15 minutes, and then added 1.32 parts of tetrabutylammonium bromide. After raising the temperature to 65° C. over 2 hours, it was further stirred for 4 hours to perform etherification reaction and rearrangement reaction. After standing to cool, 200 parts of water were added, and the water layer was separated. Furthermore, the organic layer was washed with 200 parts of water. After removing toluene under reduced pressure (1.3kPa), pass through an alumina column [150 mesh (mesh), Brockmanl...

Embodiment 1

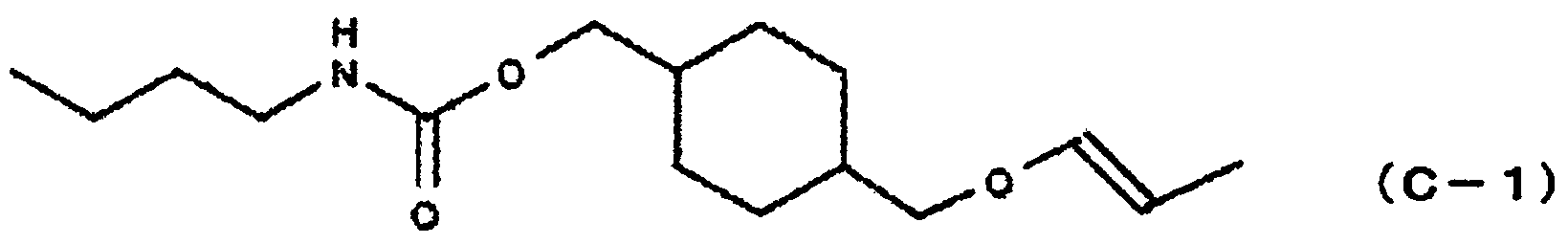

[0134] Synthesis of compound (C-1) for electrode protective film forming agent

[0135] Add 15.0 parts of 1-hydroxymethyl-4-(1-propenyloxymethyl)cyclohexane, 7.3 parts of butyl isocyanate, 100 parts of toluene and N to a flask equipped with a stirrer, a thermometer and a cooling tube, 0.5 part of N,N',N'-tetramethylethylenediamine was heated at 80°C for 8 hours. After removing toluene under reduced pressure (1.3kPa), pass through an alumina column [150 mesh, Brockmanl, standard grade, manufactured by Sigma Aldrich (Sigma Aldrich) Co., Ltd.] with hexane and ethyl acetate as developing solvent The reactant was purified to obtain 8.8 parts of a compound (C-1) represented by the following formula [yield 42%, Mn: 283 (calculated value from the chemical formula)]. Let (C-1) be an electrode protective film forming agent (D-1).

[0136] [chemical 4]

[0137]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com