Electrolyte additive, electrolyte containing additive and lithium ion battery using electrolyte

An electrolyte additive and additive technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reduced lithium ion conductivity, shortened service life, and reduced battery performance, so as not to cause volume expansion and reduce gas generation , the effect of inhibiting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

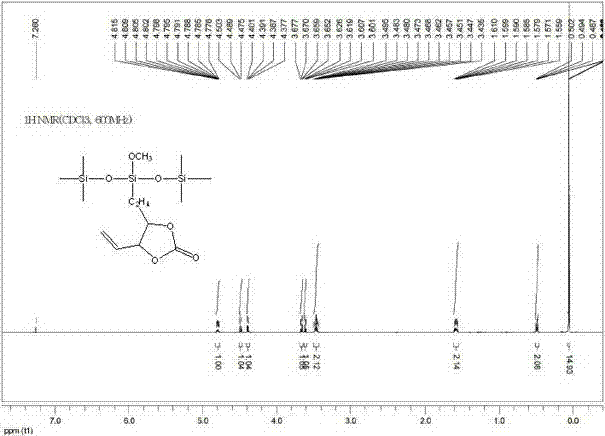

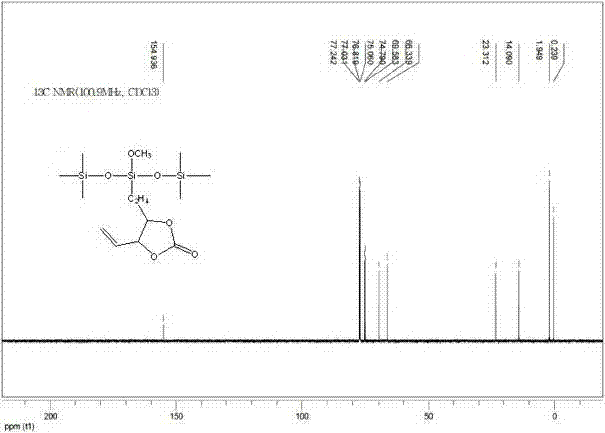

[0096] 81g of ethylene carbonate, 16g of LiPF 6 and 3 g of bis(trimethylsiloxy)methoxysilyl-vinyl butylene carbonate were uniformly mixed to obtain electrolyte solution 1.

[0097] In the argon glove box, the positive electrode sheet, separator and negative electrode sheet commonly used for lithium-ion secondary batteries are stacked in sequence and wound into a square electrode group, and the electrode group is placed in a 4.0mm×46mm×57mm The lithium-ion battery 1 is obtained through the processes of storage, formation, molding, capacity separation and aging after sealing. The nominal capacity of the battery is: 1C=750mAh.

Embodiment 2

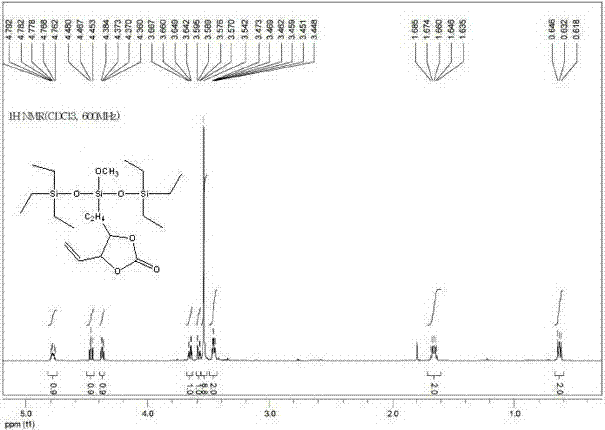

[0099] The propylene carbonate of 40g, the dimethyl carbonate of 51g, the LiClO of 8.3g 4 and 0.7 g of bis(triethylsiloxy)methoxysilyl-vinyl butylene carbonate were uniformly mixed to obtain electrolyte solution 2.

[0100] In the argon glove box, the positive electrode sheet, separator and negative electrode sheet commonly used for lithium-ion secondary batteries are stacked in sequence and wound into a square electrode group, and the electrode group is placed in a 4.0mm×46mm×57mm The battery case is softly packaged, then vacuum-baked, injected with electrolyte solution 2, sealed, and then stored, formed, formed, volume-divided and aged to obtain a lithium-ion battery 2. The nominal capacity of the battery is: 1C=750mAh.

Embodiment 3

[0102] 40g of diethyl carbonate, 20g of methyl formate, 23g of methyl acetate, 8g of LiBF 4 , 7g of LiAsF 6 and 2 g of bis(trimethylsiloxy)methoxysilyl-propenyl butylene carbonate were uniformly mixed to obtain electrolyte solution 3.

[0103] In the argon glove box, the positive electrode sheet, separator and negative electrode sheet commonly used for lithium-ion secondary batteries are stacked in sequence and wound into a square electrode group, and the electrode group is placed in a 4.0mm×46mm×57mm Soft-packed battery case, then vacuum baked, injected electrolyte 3, sealed and then stored, formed, formed, divided and aged to produce lithium-ion battery 3. The nominal capacity of the battery is: 1C=750mAh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com