Titanium-based oxide lithium ion battery anode material and performance test method thereof

A titanium-based oxide, lithium-ion battery technology, applied in battery electrodes, material analysis by electromagnetic means, material analysis, etc., can solve problems such as poor electrochemical performance of materials, achieve high specific capacity, high activity, avoid crystal The effect of increasing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a titanium-based oxide lithium-ion battery negative electrode material, comprising the following preparation steps:

[0033] (1) Preparation of silicon powder: Pickle 500g of rice husk in dilute hydrochloric acid, place it in a constant temperature water bath at 65°C for 1 hour, and then dry it in a blast drying oven. After drying, put the rice husk in a muffle furnace at 600°C Burn for 40 minutes, cool naturally, and then evenly mix rice husk ash and magnesium powder with a mass ratio of 1:0.8 and put them into the tube reactor. Inject argon, heat to 750°C and ignite for 4.5 hours, take out the ignited powder and put it in a 70°C water bath for 1 hour, then perform suction filtration, wash, and place it in a blast drying oven to dry to obtain silicon powder;

[0034] (2) Preparation of lithium titanate crystals: Lithium carbonate and titanium-based titanium dioxide with a material ratio of 2.3:5 are placed in a ball mill, and acetone is used as a...

Embodiment 6-10

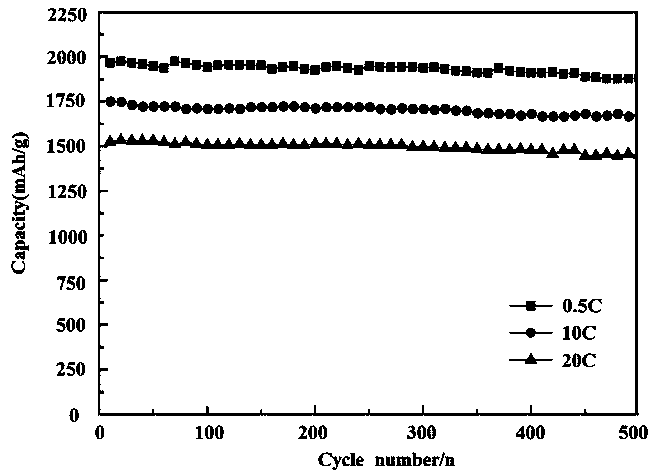

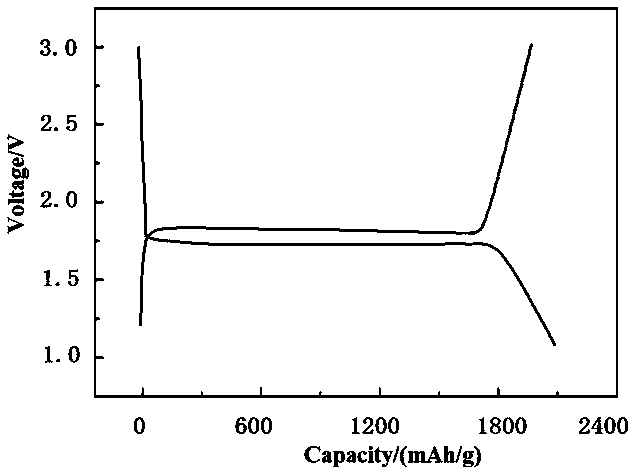

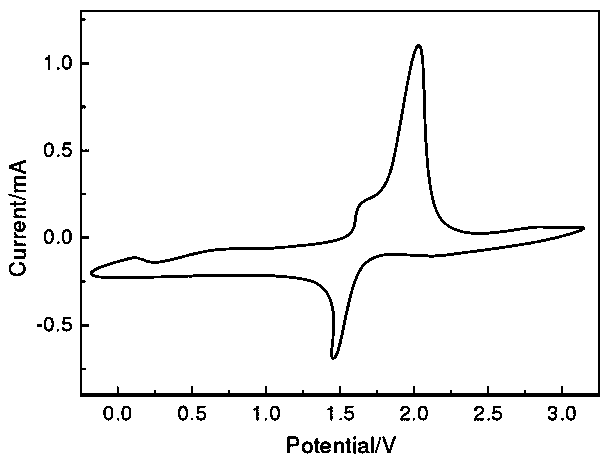

[0045] On the basis of Example 1, during the preparation of lithium titanate crystals, the microwave reaction temperature is 600°C-800°C, the content of the negative electrode material is 15% of the silicon content, 12% of the glucose content, and 2% of the carbon nanotube content. %, lithium titanate content is 71%.

[0046] Considering the influence of the microwave reaction temperature on the electrochemical performance during the preparation of lithium titanate crystals, under the condition that other conditions remain unchanged, by changing the microwave reaction temperature, the specific capacity and cycle life were investigated. Examples 6-10, as shown in Table 2 shown.

[0047] Table 2:

[0048] Example Microwave reaction temperature (°C) Current density is 1C first charge specific capacity (mAh / g) The current density is 1C first discharge specific capacity (mAh / g) first capacity retention Current density is 1C cycle 500 charge specific capacity (m...

Embodiment 11-15

[0051] On the basis of Example 1, during the preparation of lithium titanate crystals, the microwave reaction temperature is 750°C, the content of the negative electrode material is 12% of the silicon content, 5-20% of the glucose content, and 3% of the carbon nanotube content , Lithium titanate content is 70-80%.

[0052] Considering the influence of glucose content on electrochemical performance, the specific capacity and cycle life were investigated by changing the glucose content under the condition that other conditions remained unchanged. Examples 11-15 are shown in Table 3.

[0053] table 3:

[0054] Example glucose content Current density is 1C first charge specific capacity (mAh / g) The current density is 1C first discharge specific capacity (mAh / g) first capacity retention Current density is 1C cycle 500 charge specific capacity (mAh / g) Current density is 1C cycle 500 discharge specific capacity (mAh / g) 500 cycles capacity retention 11 5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com