Positive pole material of nonaqueous secondary cell and producing method thereof

A non-aqueous secondary battery and positive electrode material technology, applied in secondary batteries, non-aqueous electrolyte storage batteries, electrode manufacturing, etc., to achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

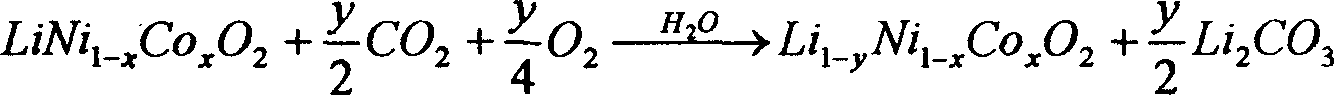

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Lithium acetate and cobalt acetate were mixed and dissolved in deionized water at a molar ratio of Li:Co=1.01:1, and then acrylic acid was added as a chelating agent, wherein the molar ratio of acrylic acid:(Li+Co)=2:1. At 80°C, slowly add the LiNi prepared in the comparative example under stirring 0.8 co 0.2 o 2 material, finally making the molar ratio LiNi 0.8 co 0.2 o 2 : LiCoO 2 =1:0.01, keep stirring until a blue-black gel is obtained. After the obtained gel was dried at 120 °C, it was calcined at 750 °C for 1 h in an air atmosphere to obtain 1% LiCoO 2 Coated LiNi 0.8 co 0.2 o 2 Material.

Embodiment 2

[0028] Experimental process is with embodiment 1, and difference is that molar ratio LiNi 0.8 co 0.2 o 2 : LiCoO 2 =1:0.05, finally get 5% LiCoO 2 Coated LiNi 0.8 co 0.2 o 2 Material.

Embodiment 3

[0030] Experimental process is with embodiment 1, and difference is that molar ratio LiNi 0.8 co 0.2 o 2 : LiCoO 2 = 1:0.10, finally get 10% LiCoO 2 Coated LiNi 0.8 co 0.2 o 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com