Method for manufacturing abrasive pattern arrangement brazed grinding wheel based on laser pre-fusion covering

A pattern arrangement and abrasive technology, applied in grinding devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of difficult coating of binders and abrasives, difficult to achieve complex pattern arrangement, low efficiency, etc. The effect of avoiding high-deficiency defects such as abrasives, improving production efficiency, and improving grinding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, spread the bonding agent 2 evenly on the grinding wheel base 1, such as Figure 1 to Figure 4 , the bonding agent 2 is preferably NiCrBSi powder, and the grinding wheel base 1 is preferably No. 45 steel.

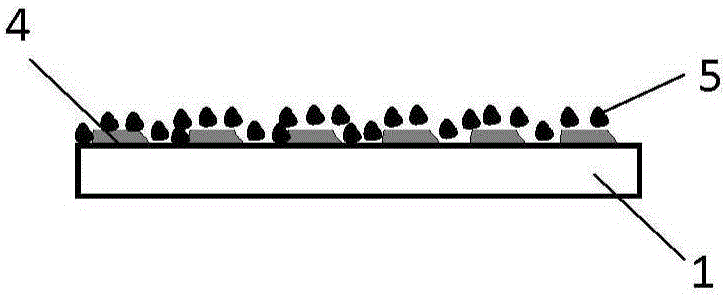

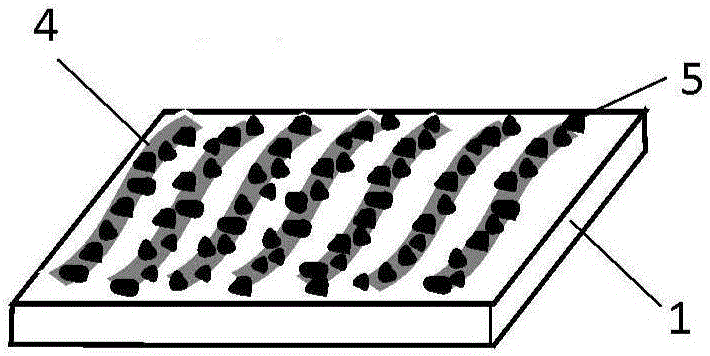

[0030] Step 2, using YAG pulsed laser 3 to perform area scanning cladding heating on the bonding agent 2 according to the designed abrasive arrangement pattern, so that the bonding agent heated by laser scanning is melted and forms a cladding layer 4, such as Figure 5 and Figure 6 As shown, the peak power of the pulsed laser is 200w, the pulse width is 5ms, the pulse frequency is 30Hz, and the scanning speed is 20mm / min.

[0031] Step 3: After the laser scanning is completed, the unscanned heating bond is removed, and the cladding layer 4 is ground to a constant thickness, with a thickness of 50um, so that a cladding layer 4 of equal height is formed on the upper surface of the grinding wheel base, such as Figure 7 and Figure 8 shown.

[0032] Step 4, ...

Embodiment example 2

[0034] Step 1, spread the bonding agent 2 evenly on the grinding wheel base 1, such as Figure 1 to Figure 4 , The bonding agent 2 is preferably NiCrP powder, and the grinding wheel base 1 is preferably 40CrMo steel.

[0035] Step 2, using a continuous laser to scan and clad the bonding agent 2 according to the designed abrasive arrangement pattern, so that the bonding agent heated by laser scanning melts and forms a cladding layer 4; Figure 5 and Figure 6 As shown, the laser power is 120w, the spot diameter is 1.5mm, and the scanning speed is 20mm / min.

[0036] Step 3: After the laser scanning is completed, the unscanned heating bonding agent is removed, and the cladding layer 4 is ground to a fixed thickness, with a thickness of 150um, so that a cladding layer 4 of equal height is formed on the upper surface of the grinding wheel base, such as Figure 7 and Figure 8 shown.

[0037] Step 4, coating a layer of viscose on the upper surface of the grinding wheel base 1, a...

Embodiment example 3

[0039] Step 1, spread the bonding agent 2 evenly on the grinding wheel base 1, such as Figure 1 to Figure 4 , the bonding agent 2 is preferably AgCuTi powder, and the grinding wheel base 1 is preferably No. 45 steel.

[0040] Step 2, using YAG pulsed laser 3 to perform area scanning cladding heating on the bonding agent 2 according to the designed abrasive arrangement pattern, so that the bonding agent heated by laser scanning is melted and forms a cladding layer 4, such as Figure 5 and Figure 6 As shown, the laser peak power is 200w, the pulse width is 5ms, the pulse frequency is 30Hz, and the scanning speed is 20mm / min.

[0041] Step 3: After the laser scanning is completed, the unscanned heating bond is removed, and the cladding layer 4 is ground to a constant thickness, with a thickness of 125um, so that a cladding layer 4 of equal height is formed on the upper surface of the grinding wheel base, such as Figure 7 and Figure 8 shown.

[0042] Step 4, sprinkle cubic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com