A frequency conversion constant pressure water supply component

A variable frequency constant pressure and component technology, applied in water supply installations, water conservation, water supply main pipelines, etc., can solve problems such as increased pressure, cracking of the outer wall of the pipeline, excessive pressure difference between the inside and outside of the pipeline, etc., to improve efficiency, increase strength, The effect of improving the efficiency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

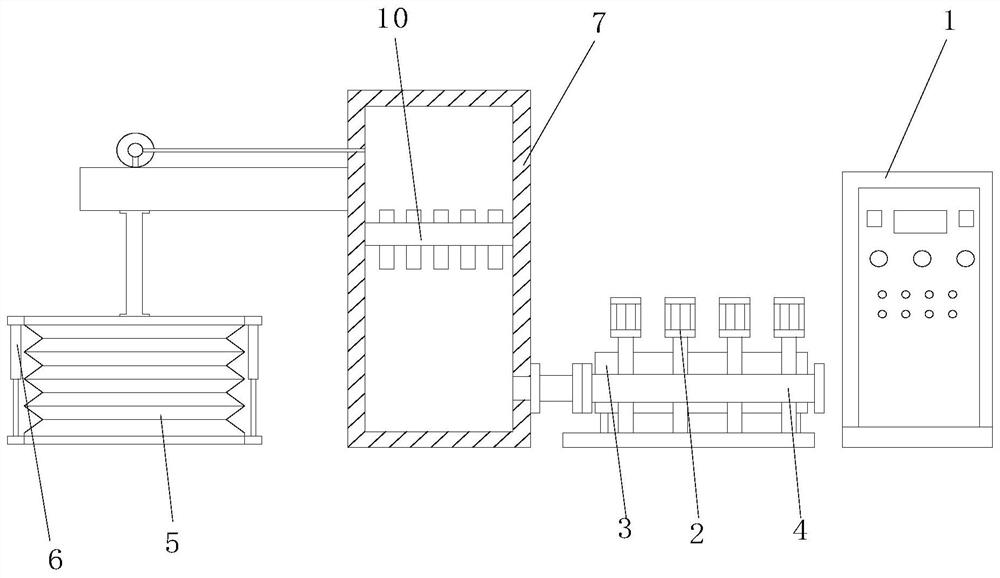

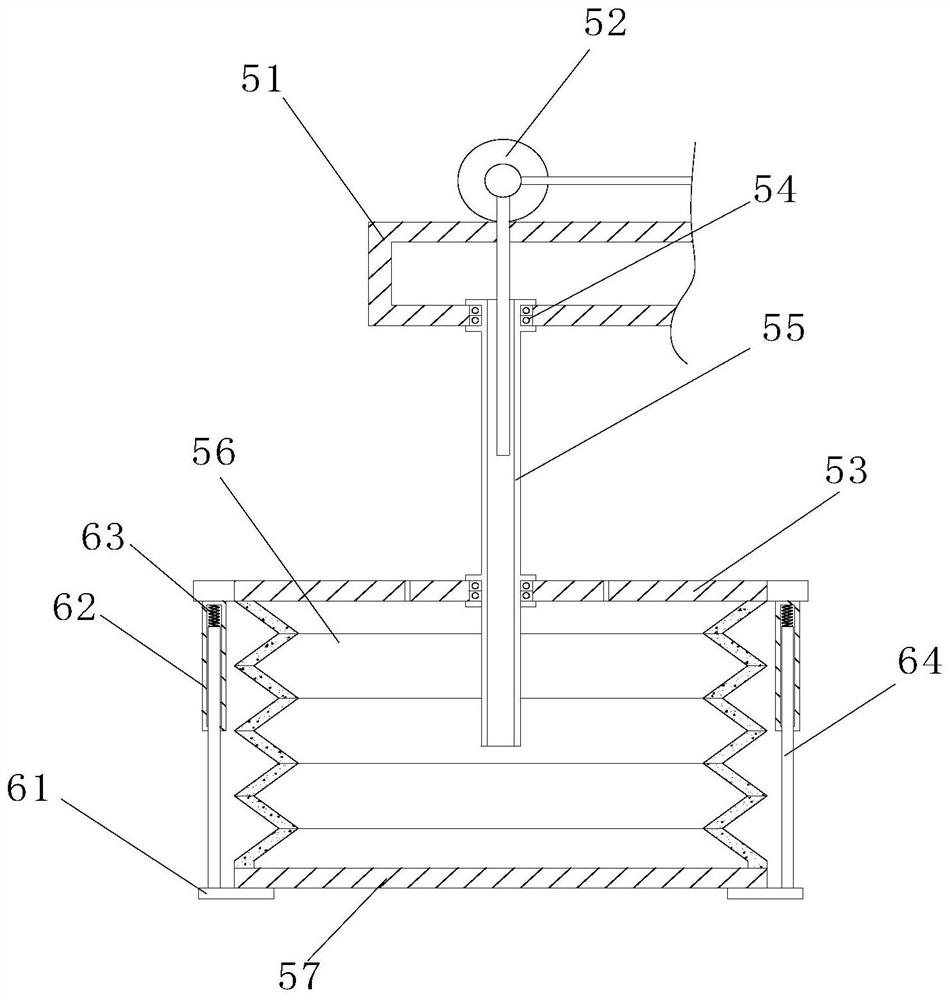

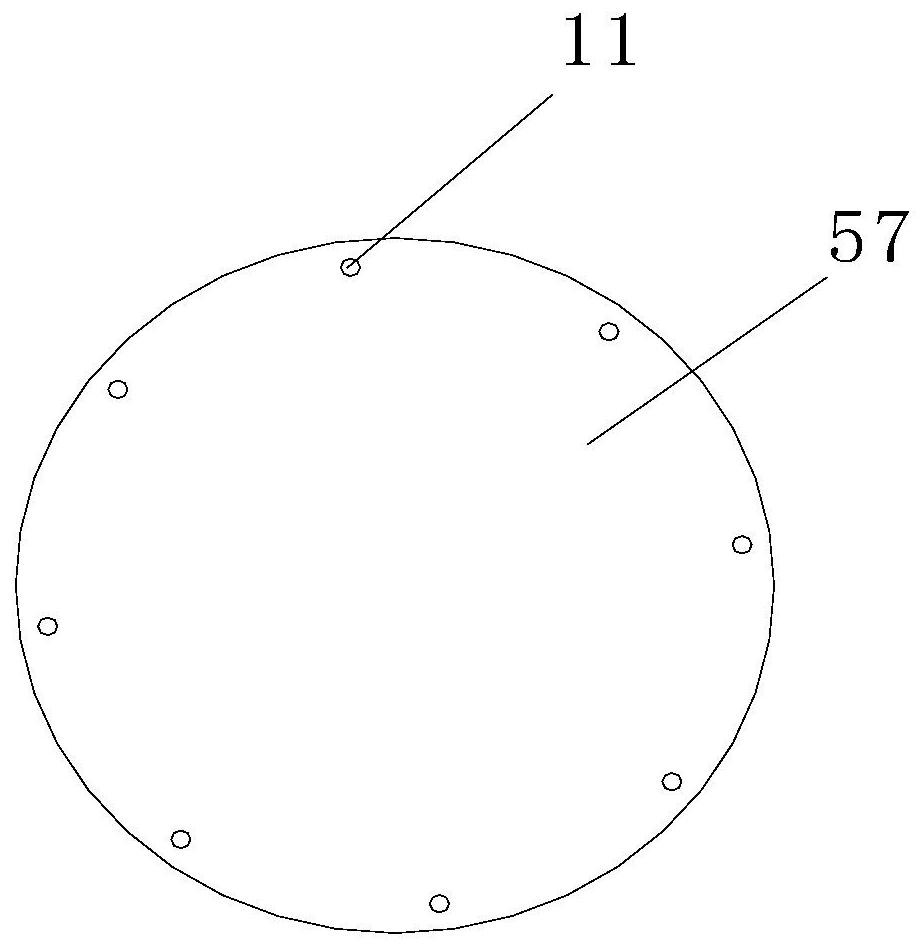

[0042] Example 1: Please refer to Figure 1-4 , a frequency conversion constant pressure water supply assembly, including an electric control cabinet 1, a water pump group 2, an air pressure tank 3, a water supply pipe 4, a water collection mechanism 5, a telescopic mechanism 6 and a water storage tank 7, and the inside of the electric control cabinet 1 is fixedly installed with electric control system and ABB frequency converter, the electric control cabinet 1 is electrically connected to the water pump group 2, the water pump group 2, the air pressure tank 3 and the water supply pipe 4 are all arranged on the left side of the electric control cabinet 1, and the water inlet end of the water supply pipe 4 is connected to the water storage The water tank 7 is fixedly connected and communicated. The interior of the water storage tank 7 is fixedly equipped with a filter mechanism 10. The filter mechanism 10 adopts a reverse osmosis membrane filter mechanism. It is fixedly install...

Embodiment 2

[0046] Example 2: Please refer to Figure 5-6 , on the basis of Embodiment 1, rubber sleeves 13 are sleeved at the twists and turns of the outer wall of bellows 56. When the bellows 56 is stretched out, the rubber sleeve 13 will also be stretched out, thereby having The effect of accommodating part of the water through the through hole 14, and then when the water collecting mechanism 5 stops using, etc., the rubber sleeve 13 also shrinks during the shrinkage process of the bellows 56, and the water stored in it is squeezed out. Water is used to flush the inner wall of the bellows 56. Through the setting of the rubber sleeve 13, the rubber sleeve 13 is fixedly connected to the folds of the outer wall of the bellows 56, thereby increasing the strength of the fragile position of the bellows 56, and then the rubber sleeve 13 is connected with the connecting rod B15 During the stretching process, part of the water entering the bellows 56 will be stored, and then when the water col...

Embodiment 3

[0049] Example 3: Please refer to Figure 7-8 , on the basis of Embodiment 2, the bottom surface of the connecting pipe 55 is fixedly connected with the clean water tank 17, the inside of the clean water tank 17 is hollow and communicates with the connecting pipe 55, and the bottom surface of the scraper 16 is provided with five water inlet grooves A18, and the scraper Inside 16, a water inlet tank B19 is provided above the water inlet tank A18. The water inlet tank B19 is connected to the five water inlet tanks A18. The top surface of the water inlet tank B19 is provided with a water outlet hole 20. The inner wall of the water outlet hole 20 is fixedly connected with a water delivery pipe 21. The end of the water delivery pipe 21 away from the water outlet hole 20 is fixedly connected and communicated with the clean water tank 17, and the inner wall of the water inlet tank A18 is fixedly equipped with a filter screen 22. After the water enters the bellows 56 and the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com