Spraying combustion device and method for compounding metallic oxide powder by spraying

A technology of spray combustion and oxide powder, which is applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, feeding devices, etc., can solve the problems of difficult to effectively control product shape and size, increase production cost, The problem of high proportion of organic components in the precursor can achieve the effect of shortening the process flow and preparation time, saving space and cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

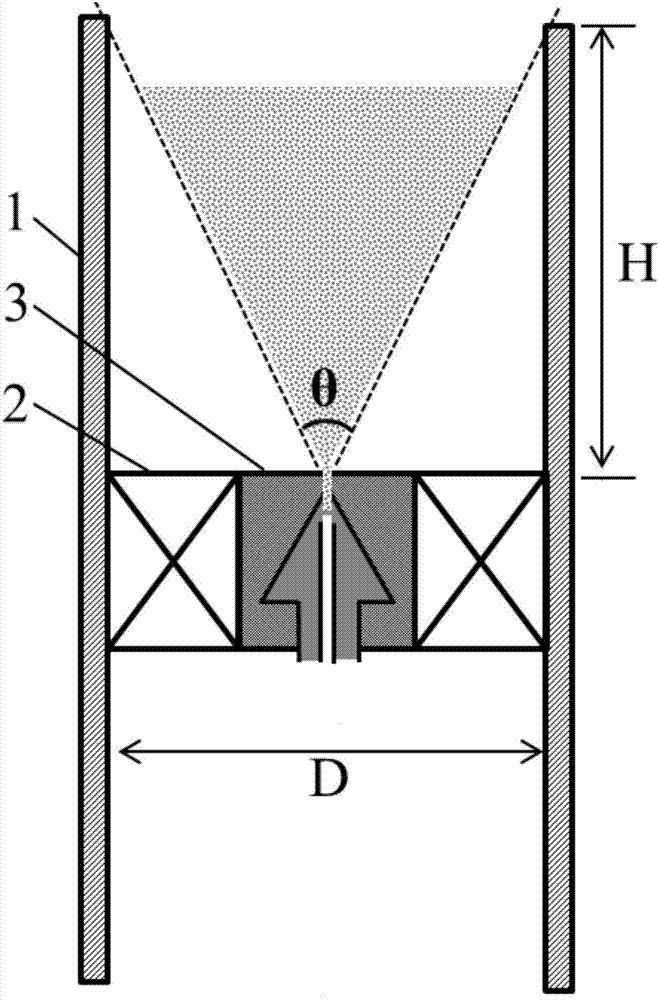

[0070] like figure 1 As shown, the present embodiment provides a spray combustion device, which includes a gun body 1, a flow guiding member 2 and an atomizing nozzle 3; the gun body 1 includes a cavity; the flow guiding member 2 is arranged on Inside the cavity, it can slide relatively along the cavity; the atomizing nozzle 3 penetrates the flow guide member 2, and can slide along the cavity with the flow guide member 2; the flow guide member 2 The atomizing nozzle 3 is connected with the inlet of the flammable gas, and the atomization nozzle 3 is connected with the inlet of the liquid precursor.

[0071] The flow guiding member 2 is a distribution plate; the atomizing nozzle 3 is a two-fluid atomizing nozzle; the gun body 1 includes a cylindrical cavity; the atomizing nozzle 3 penetrates the flow guiding member 2 at the center position.

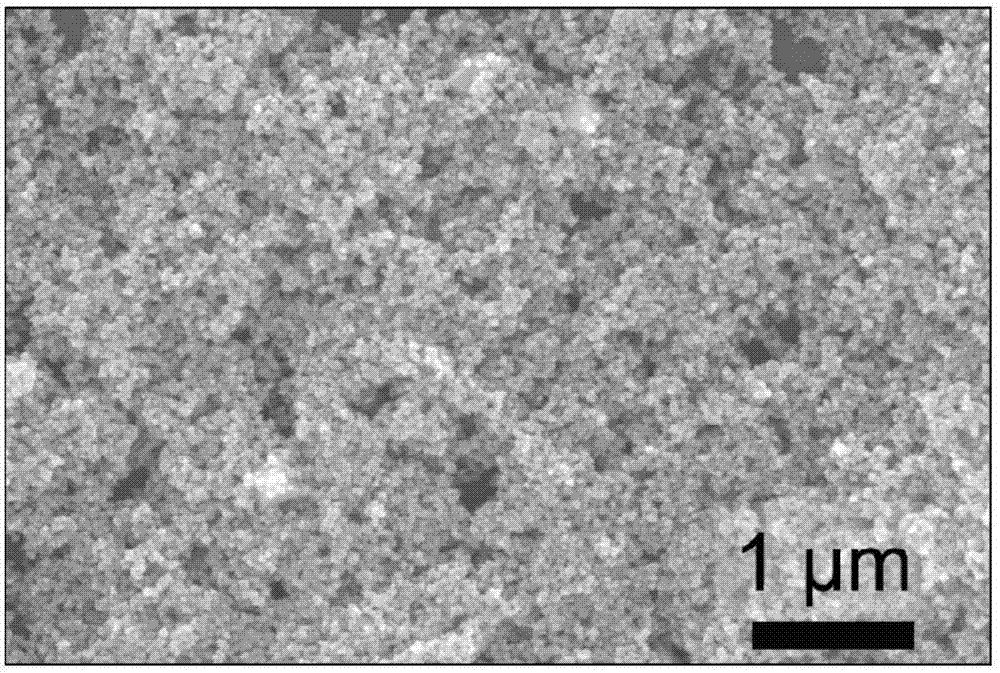

[0072]Synthesis of Nanoscale CeO 2 Powder, SnO 2 Powder and WO 3 Powder:

[0073] Prepare 0.5M Ce(NO 3 ) 3 ·6H 2 O aqueous sol...

Embodiment 2

[0077] This embodiment provides a spray combustion device. Except that the flow guide member 2 is a flow guide groove, other components and structures of the device are completely the same as the spray combustion device in Embodiment 1.

[0078] Synthesis of micron-sized particles of CeO 2 Powder, Y 2 o 3 Powder and Al 2 o 3 Powder:

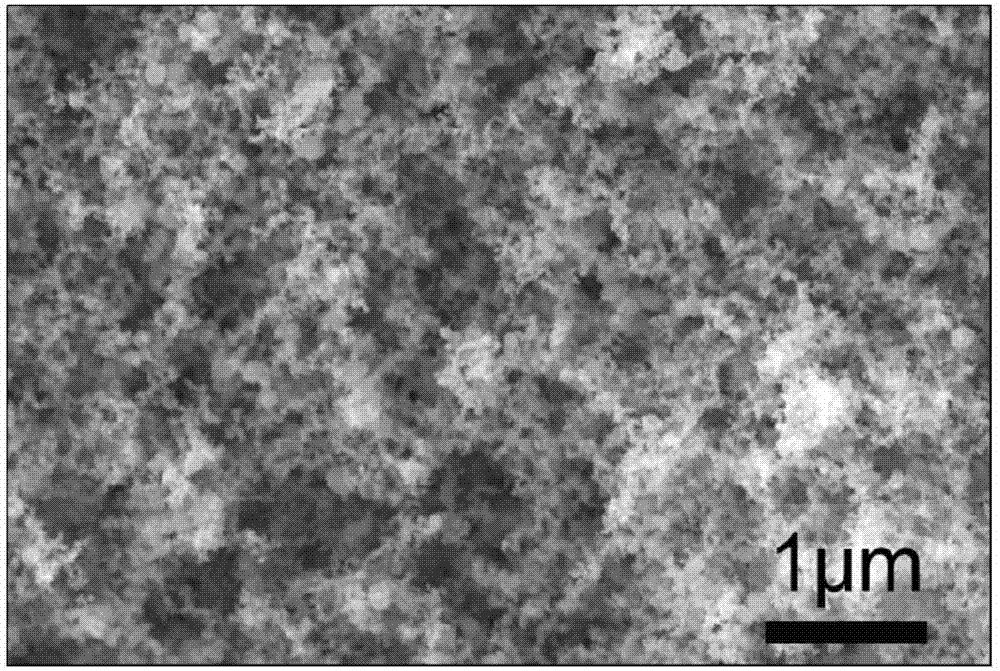

[0079] Prepare 0.5M Ce(NO 3 ) 3 ·6H 2 O aqueous solution; the mixed gas of methane, oxygen and argon is exported from the guide member of the above-mentioned spray combustion device, and burned at the port of the gun body to generate a stable temperature zone of about 1000 °C; the aqueous solution of metal salt is burned from the spray The atomizing nozzle of the device is sprayed to the temperature zone to obtain CeO 2 Powder. As shown in Figure 3(a), the obtained CeO 2 The powder is micron-sized particles.

[0080] Prepare 0.5M Y(NO 3 ) 3 ·6H 2 O aqueous solution, other conditions are the same as above for the preparation of...

Embodiment 3

[0083] This embodiment provides a spray combustion device. Except that the flow guide member 2 is a honeycomb body and the atomization nozzle 3 is a pressure atomization nozzle, other components and structures are completely the same as those of the spray combustion device in Example 1. same.

[0084] Synthesis of nanoscale WO 3 / CeO 2 Composite powder:

[0085] Will [(NH 4 )6H 2 W 12 o 40 ]·4H 2 O and Ce(NO 3 ) 3 ·6H 2 O is mixed and dissolved in pure water to obtain an aqueous solution in which the concentration of W atoms is 0.1M and the concentration of Ce atoms is 1M (that is, the atomic ratio of tungsten to cerium is 1:10); Combustion at the port of the gun body produces a stable temperature zone of 2000-2500 ° C; the aqueous solution of the metal salt is sprayed from the atomizing nozzle of the spray combustion device to the temperature zone to obtain WO 3 / CeO 2 Composite powder. like Figure 4 As shown, the resulting WO 3 / CeO 2 The composite powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com