Metal-oxygen secondary battery

A secondary battery and oxygen technology, applied in battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problem of the disordered growth of lithium peroxide hindering the effective occurrence of reactions, cracks and The growth direction of dendrites is uncontrollable, which hinders industrial utilization and other problems, and achieves the effects of solving dendrite effects, high stability, and favorable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

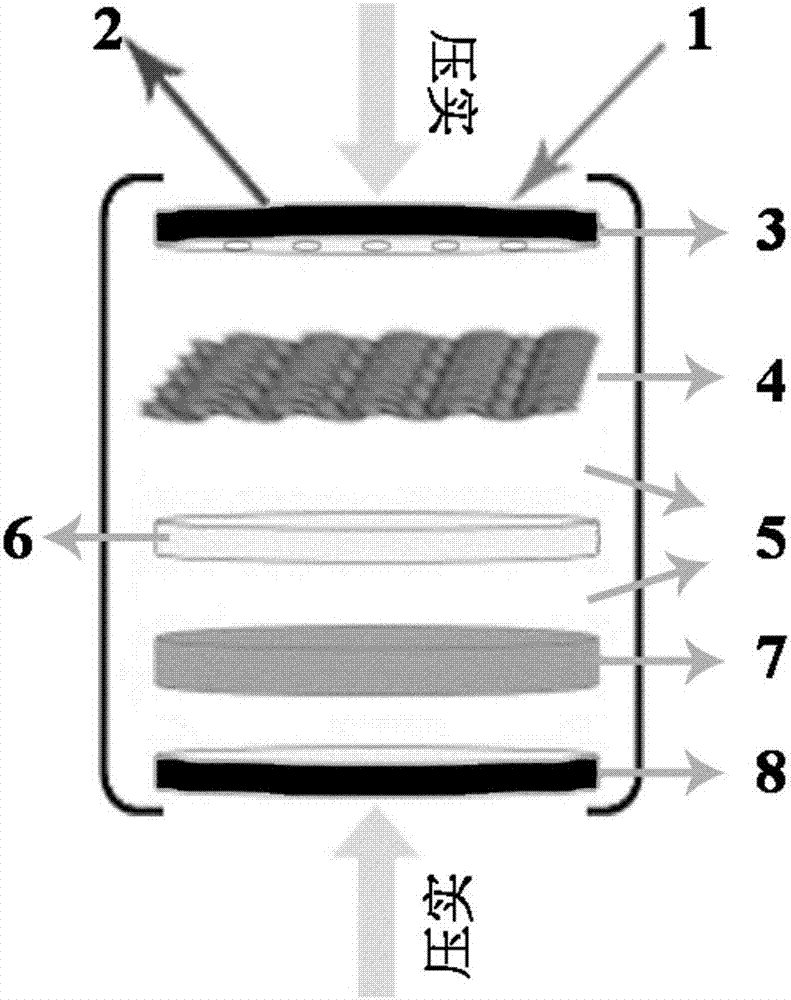

[0084] This embodiment provides a metal-air battery based on lithium-sodium alloy, its structure can refer to figure 1 As shown, the cathode gas (ie working gas) used in this embodiment is oxygen, and the battery number of this embodiment is marked as A1.

[0085] The negative electrode of the present embodiment is made of self-made lithium-sodium alloy sheet;

[0086] Wherein the lithium-sodium alloy sheet can be made by the following method:

[0087] Cut the dry lithium plate and the dry sodium strip into small pieces, mix the lithium and sodium pieces into a stainless steel container, heat the stainless steel container on a heater until the metal lithium and metal sodium inside melt, and record the melting temperature . Cool down to room temperature, and roll the resulting lithium-sodium alloy into flakes with a thickness of 0.2 to 0.3 mm. All the above operations are completed in an argon-protected glove box.

[0088] The lithium-sodium alloy prepared by the above-menti...

Embodiment 2

[0110] This embodiment provides a lithium-sodium alloy-oxygen rechargeable secondary battery, denoted as A2, whose structure is basically the same as that of the battery provided in embodiment 1. In this embodiment, the ratio of the metal negative electrode lithium and sodium alloy varies.

[0111] The negative electrode in this embodiment can be made by the following method:

[0112] Cut the dry lithium plate and the dry sodium strip into small pieces, mix the lithium and sodium pieces into a stainless steel container, heat the stainless steel container on a heater until the metal and metal sodium inside melt, and record the melting temperature. Cool down to room temperature, and roll the resulting lithium-sodium alloy into flakes with a thickness of 0.2 to 0.3 mm. All the above operations are completed in an argon-protected glove box.

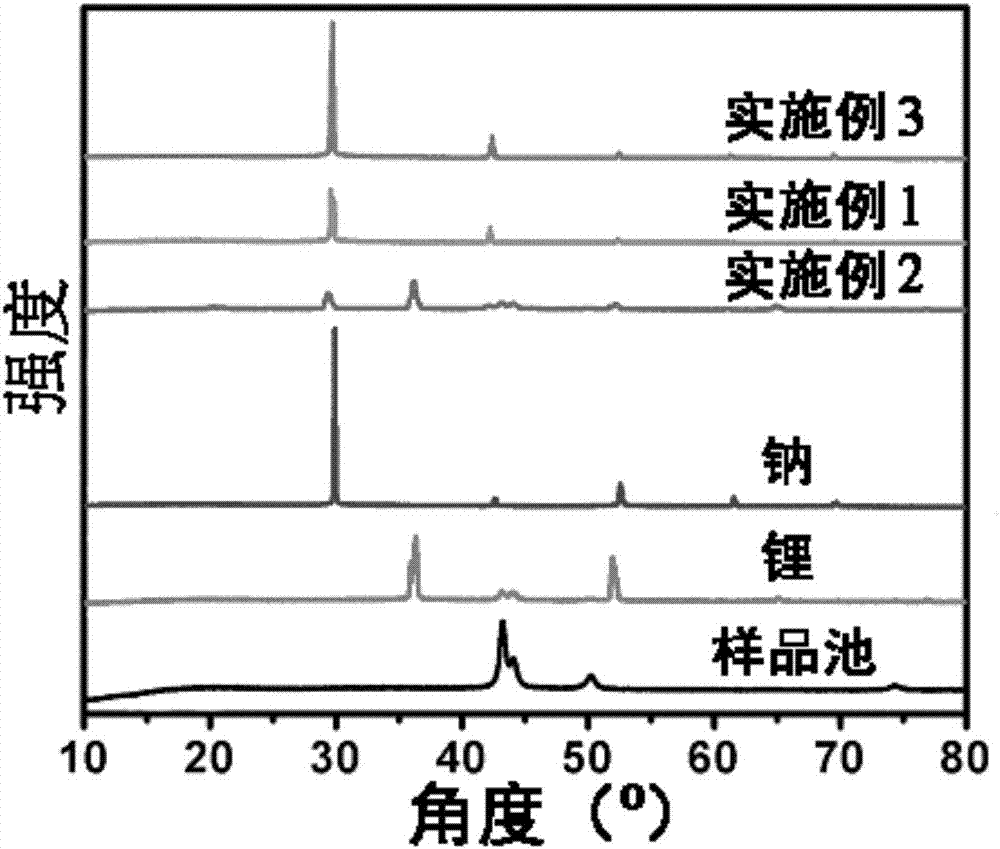

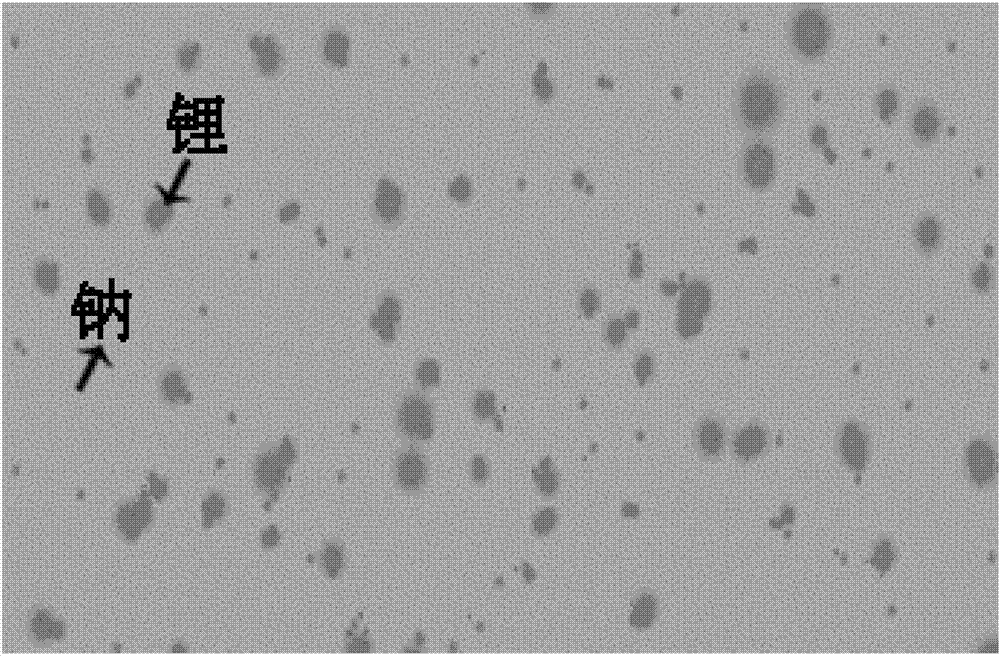

[0113] The lithium-sodium alloy prepared by the above-mentioned steps of the present invention is detected. see figure 2 , figure 2 It...

Embodiment 3

[0122] This embodiment provides a lithium-sodium alloy-oxygen rechargeable secondary battery, denoted as A3, whose structure is basically the same as that of the battery provided in embodiment 1. In this embodiment, the ratio of the metal negative electrode lithium and sodium alloy varies.

[0123] The negative electrode in this embodiment can be made by the following method:

[0124] Cut the dry lithium plate and the dry sodium strip into small pieces, mix the lithium and sodium pieces into a stainless steel container, heat the stainless steel container on a heater until the metal and metal sodium inside melt, and record the melting temperature. Cool down to room temperature, and roll the resulting lithium-sodium alloy metal block into a thin sheet with a thickness of 0.2 to 0.3 mm. All the above operations are completed in an argon-protected glove box.

[0125] The lithium-sodium alloy prepared by the above-mentioned steps of the present invention is detected. see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com