Positive electrode lithium supplement agent and preparation method and application thereof

A technology for supplementing lithium and positive electrodes is applied in the field of positive lithium supplements and their preparation, and can solve the problems of increasing cell impedance, catalytic electrolyte gas production, and less positive lithium supplements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Correspondingly, an embodiment of the present application also provides a preparation method of the above-mentioned positive electrode lithium supplement, including:

[0071] S01, performing lattice reconstruction on the oxide-type positive electrode active material to obtain a catalyst; wherein, the intensity ratio of the (104) crystal plane diffraction peak and the (003) crystal plane diffraction peak of the catalyst is less than or equal to 2;

[0072] S02, physically fuse the catalyst with a lithium-rich material to obtain a positive electrode lithium supplement; wherein the catalyst is used to catalyze the decomposition of the lithium-rich material to release active lithium, and the lithium-rich material includes lithium oxide, peroxide At least one of lithium, lithium fluoride, lithium carbonate, lithium oxalate, and lithium acetate.

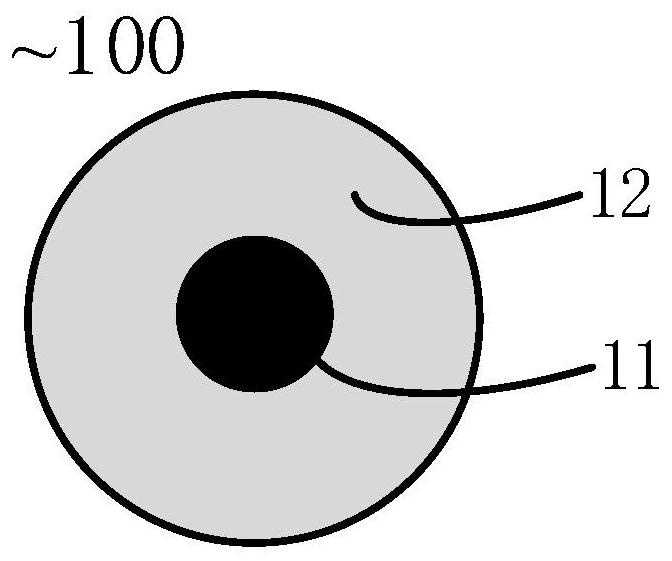

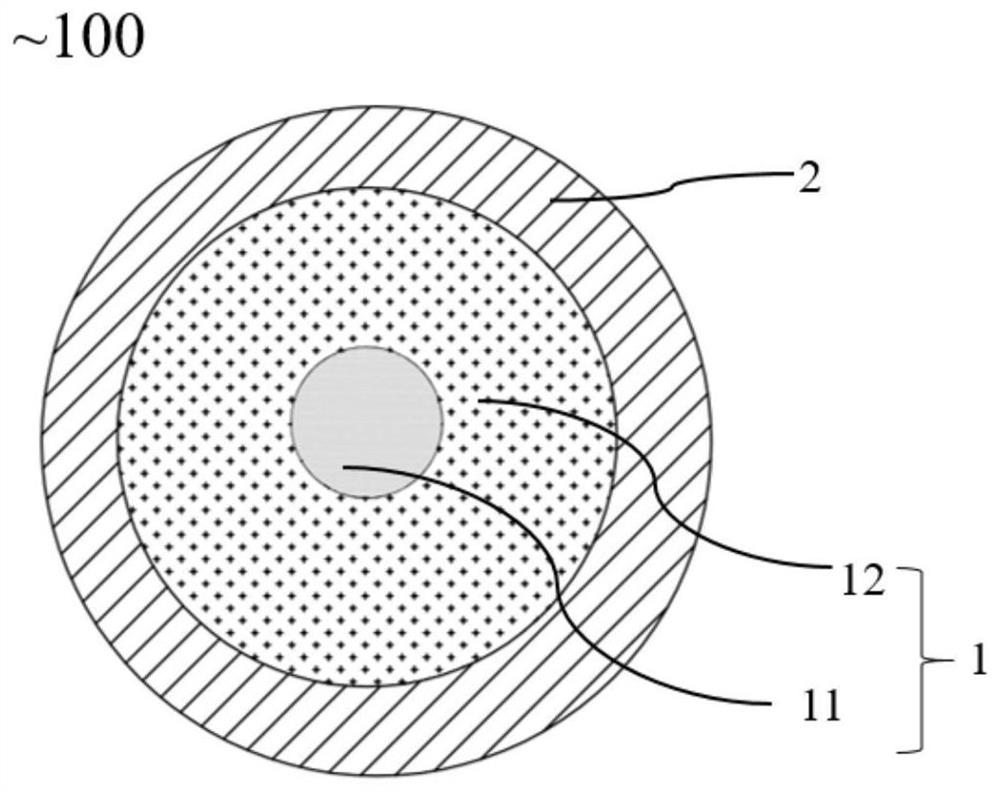

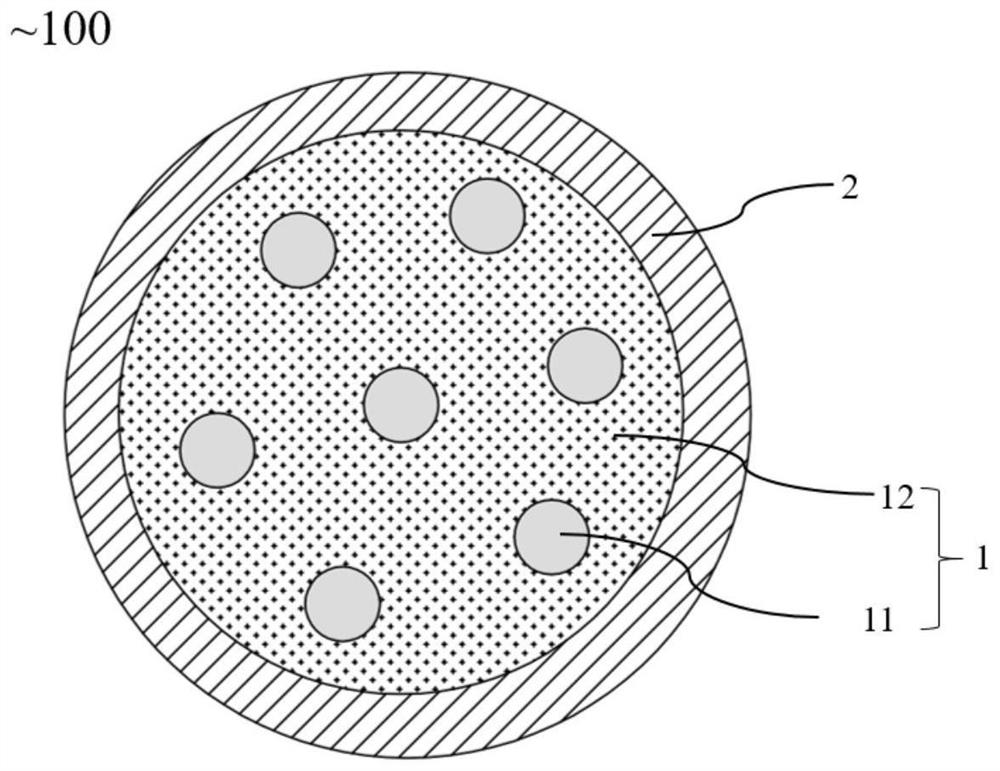

[0073] This preparation method can produce as figure 1 The positive lithium supplement in which the catalyst and the lithium-rich...

Embodiment 1

[0099] A preparation of a positive electrode lithium supplement, comprising:

[0100] Use lithium cobalt oxide LiCoO 2 As a catalyst precursor, high-energy ball milling was carried out for 48 hours at a ball-to-material ratio of 20:1 and a rotational speed of 350 r / min to achieve lattice reconstruction to obtain a catalyst; then the catalyst and lithium-rich material Li 2 O is mixed at a mass ratio of 4:1, and ordinary ball milling is carried out at a rotational speed of 200 r / min for 6 hours. After that, the mixed powder after ball milling is placed in a tube furnace and heated to 400 ° C, and the dry air is continuously fed at a flow rate of 60 sccm. 2 hours to make part of Li 2 O reacts to form a lithium carbonate protective layer, and after cooling to room temperature, the obtained powder is ground and sieved to obtain a positive electrode lithium supplement.

[0101] A preparation of a soft pack battery, comprising:

[0102] 1) Preparation of battery cathode sheet: tak...

Embodiment 2

[0113] A preparation of a positive electrode lithium supplement, comprising:

[0114] Commercially available lithium cobalt oxide powder with a particle size in the range of 2-50 μm is selected as the catalyst precursor, and boron oxide powder and lithium aluminum titanium phosphate (LATP) powder are added thereto to obtain a mixed powder; wherein, in the mixed powder, boron oxide powder The mass ratio of LATP powder is 1%; the mixed powder is put into the ball mill tank, and the ball-to-material ratio is 15:1 and the rotation speed is 380r / min for 12h of high-energy ball milling, and then the mixed powder is transferred to the tube type In the furnace, sintered at 700°C for 8 hours in an air atmosphere, and then ground and sieved to obtain a lattice-reconstructed lithium cobalt oxide, that is, a catalyst, whose particle size is 10nm-2μm, and its (003) crystal plane diffraction The intensity ratio of the peak to the (104) crystal plane diffraction peak is 1.55;

[0115] Combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com