Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

a technology of glass-ceramic and electronic components, applied in the direction of printed circuits, electrical devices, natural mineral layered products, etc., can solve the problem of low melting point of metal, and achieve the effect of reducing manufacturing costs, easy control, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

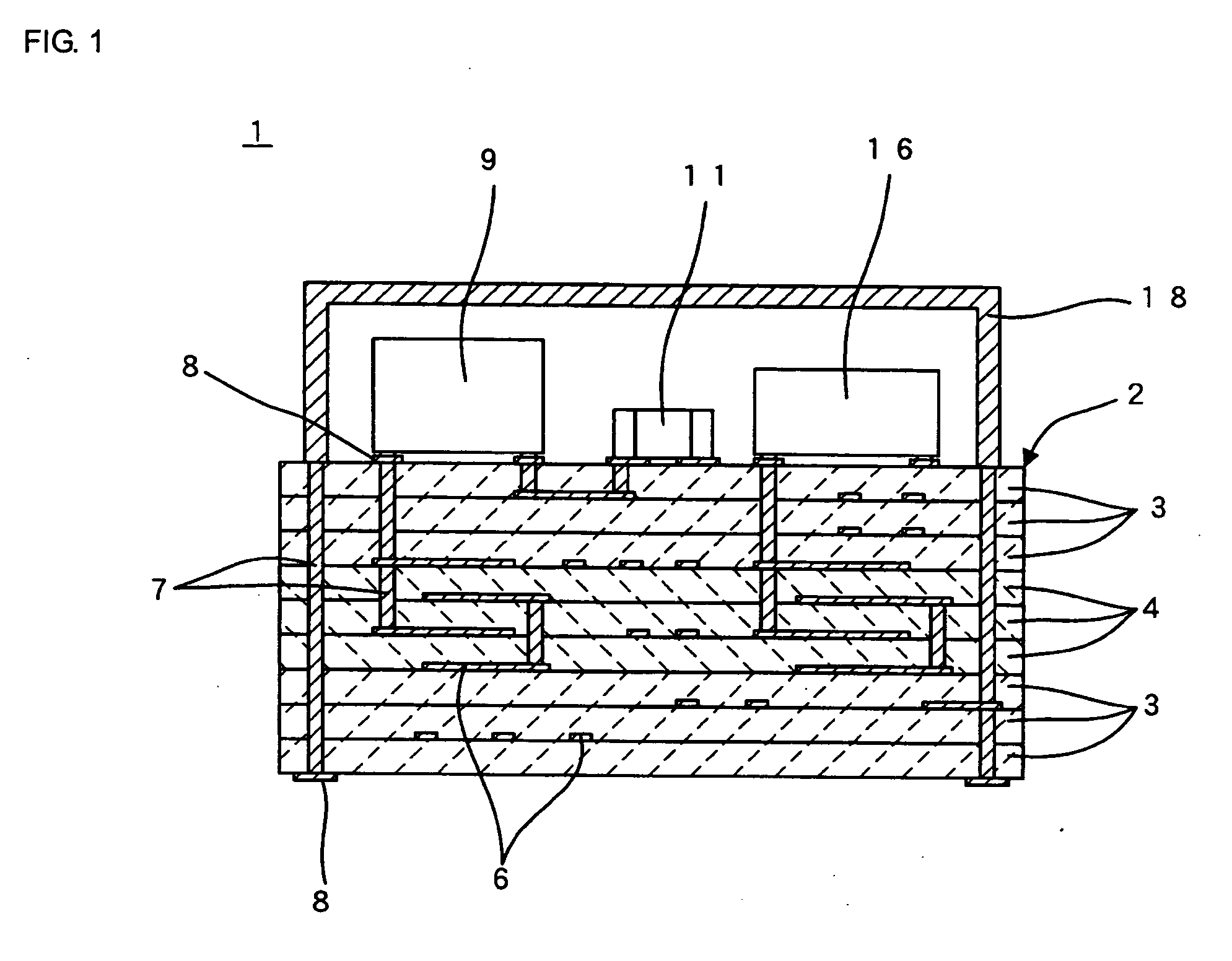

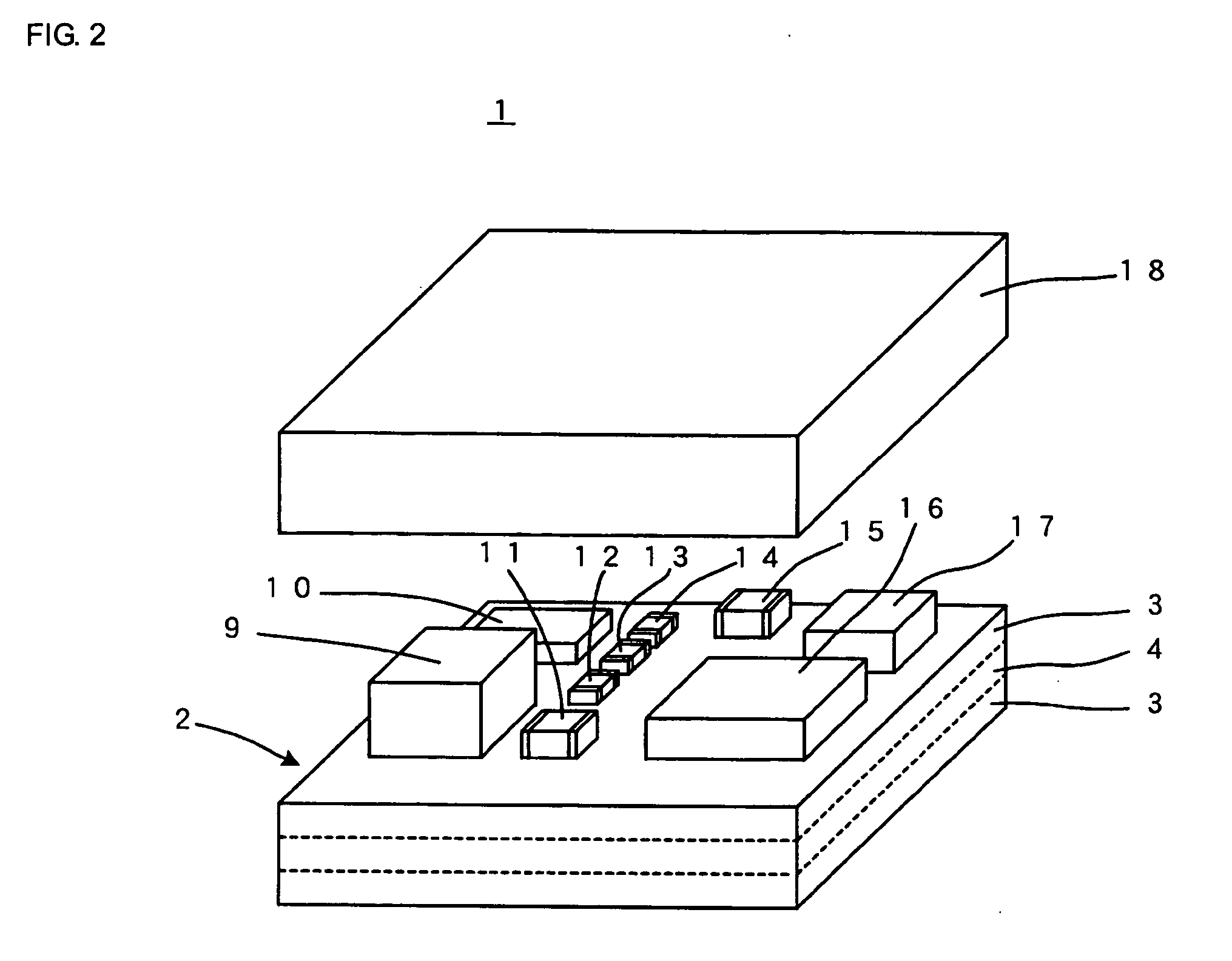

Image

Examples

Embodiment Construction

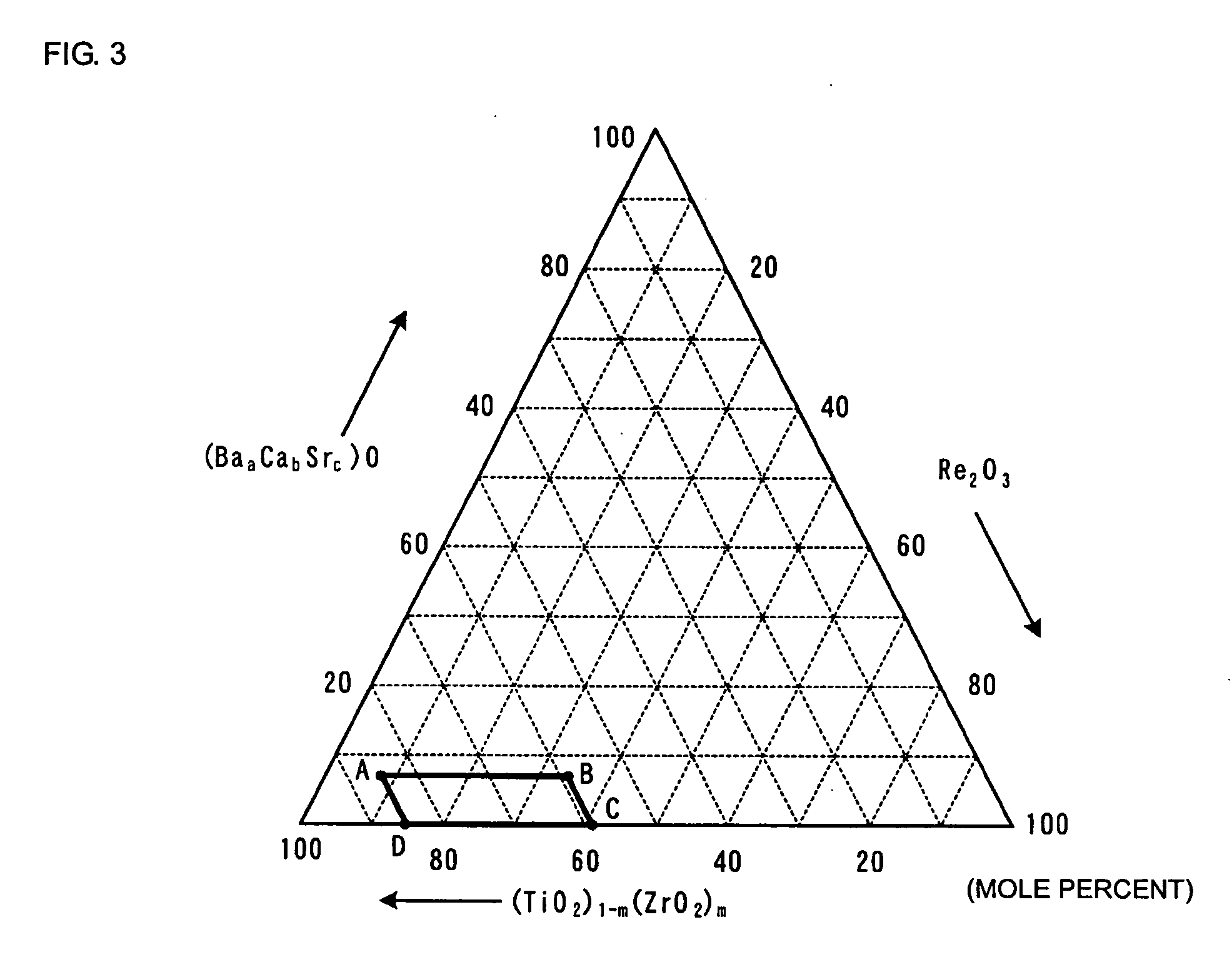

[0042] A glass-ceramic composition according to an embodiment of the present invention contains first ceramic particles principally containing forsterite (Mg2SiO4); second ceramic particles principally containing at least one selected from the group consisting of calcium titanate (CaTiO3), strontium titanate (SrTiO3), and titanium oxide (TiO2); and borosilicate glass particles. The composition of the borosilicate glass particles is particularly notable.

[0043] The borosilicate glass particles preferably contain about 3% to 15% lithium oxide (Li2O), about 20% to 50% magnesium oxide (MgO), about 15% to 30% boron oxide (B2O3), about 10% to 45% silicon oxide (SiO2), about 6% to 20% zinc oxide (ZnO), and 0% to about 15% aluminum oxide (Al2O3) on a weight basis. Since the composition of the borosilicate glass particles is suitable for forming Li2(Mg, Zn)SiO4 grains, there is an advantage in that a sintered body made of the glass-ceramic composition has a high Q value and high reliability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| median diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com