Co3O4/MXene composite catalyst, and preparation method and application thereof

A composite catalyst and reaction technology, which is applied to fuel cell type half cells and primary cell type half cells, electrical components, battery electrodes, etc., can solve the problems of poor cycle performance, difficult decomposition, low energy efficiency, etc. The effect of cycle life, improved catalytic ability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

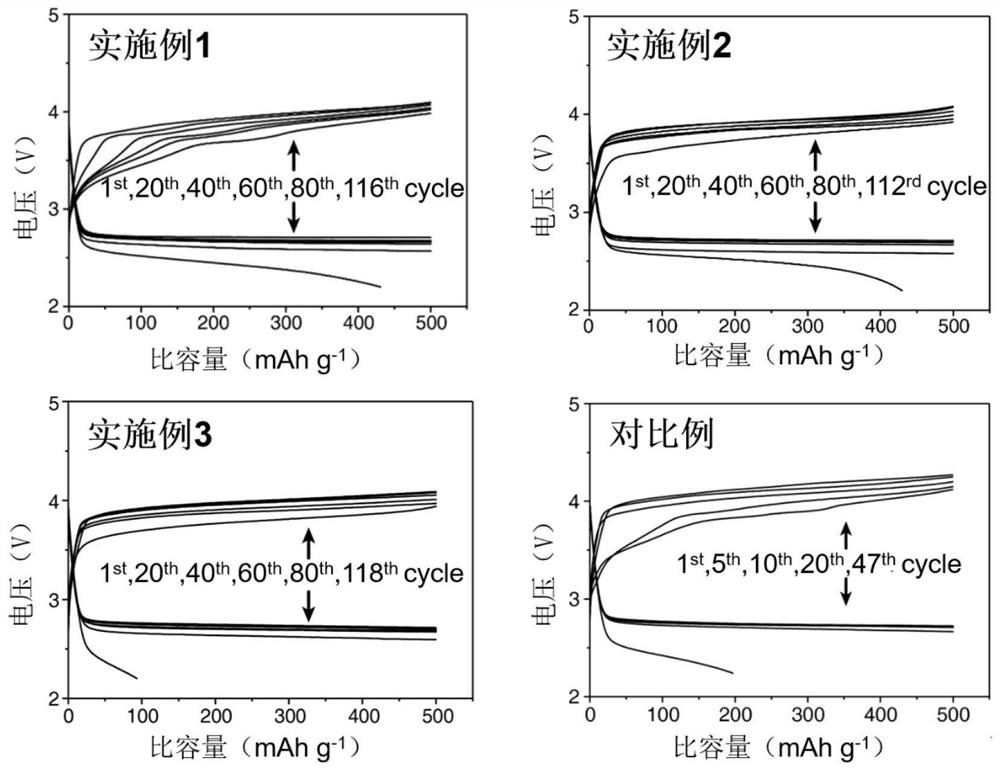

Embodiment 1

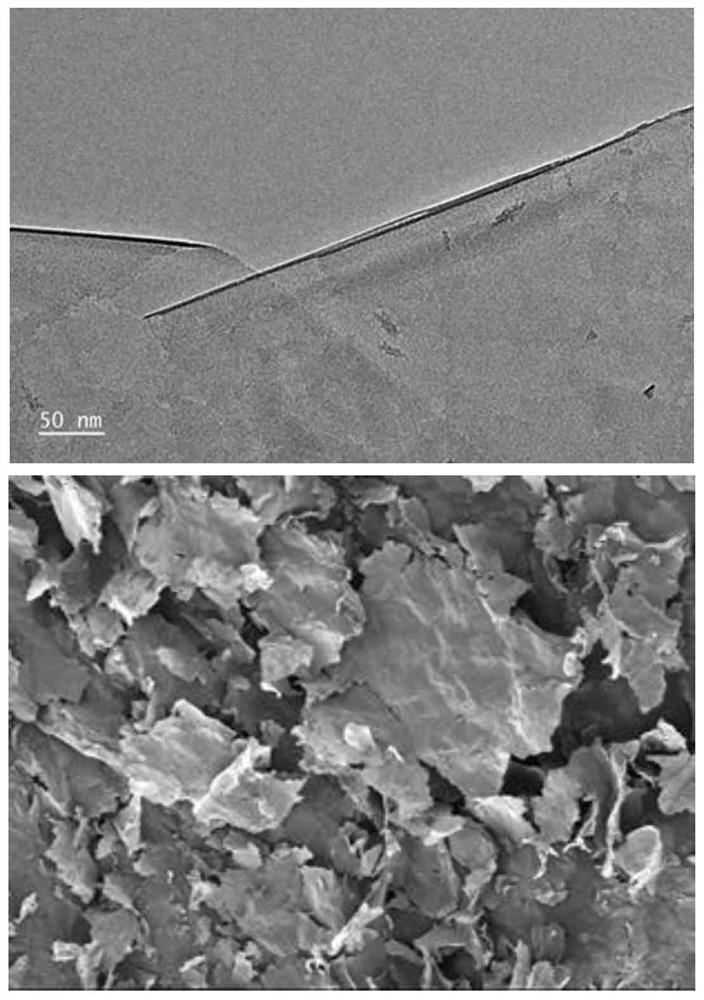

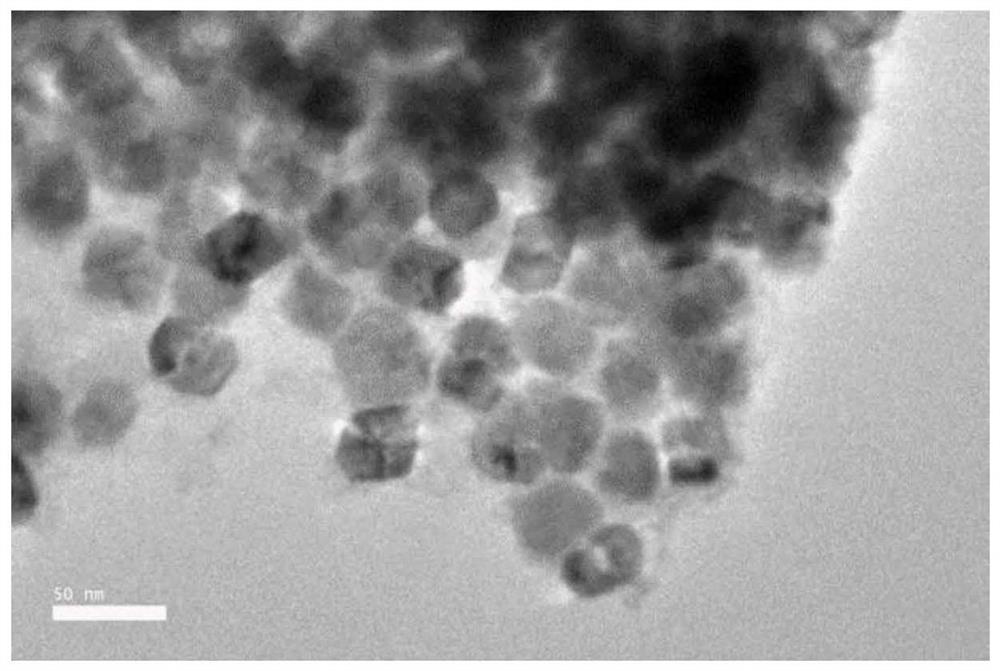

[0057] A kind of Co 3 o 4 The preparation method of / MXene composite catalyst comprises the following steps:

[0058] Add 0.55g of lithium fluoride powder into 15mL of 1M hydrochloric acid solution, stir magnetically until the solution is clear, and obtain a mixed solution of lithium fluoride and hydrochloric acid; then take 0.55g of MAX phase material (Ti 3 AlC 2 ) powder, under magnetic stirring, slowly add it into the prepared mixed solution of lithium fluoride and hydrochloric acid, heat and stir in an oil bath at 35° C. at a speed of 450 rpm for 96 h. After the stirring is completed, the reaction precipitate is centrifuged and washed 3 times with deionized water (the centrifugal speed is 10000rpm, and the washing time is 20min), until the pH of the centrifuged supernatant is about 6-7, the multilayer MXene can be prepared, and the Sealed for later use. The prepared multi-layer MXene was redispersed with deionized water, shaken and stripped for 60 min, and then centrifu...

Embodiment 2

[0065] A kind of Co 3 o 4 The preparation method of / MXene composite catalyst comprises the following steps:

[0066] Add 1.09g of lithium fluoride powder into 20mL of 3M hydrochloric acid solution, stir magnetically until the solution is clear, and obtain a mixed solution of lithium fluoride and hydrochloric acid; then take 1.09g of MAX phase material (Ti 3 AlC 2 ) powder, under magnetic stirring, slowly add it into the prepared mixed solution of lithium fluoride and hydrochloric acid, heat and stir in an oil bath at 35° C. at a speed of 450 rpm for 96 h. After the stirring is completed, the reaction precipitate is centrifuged and washed 3 times with deionized water (the centrifugal speed is 10000rpm, and the washing time is 20min), until the pH of the centrifuged supernatant is about 6-7, the multilayer MXene can be prepared, and the Sealed for later use. The prepared multi-layer MXene was redispersed with deionized water, shaken and stripped for 60 min, then centrifuged ...

Embodiment 3

[0072] A kind of Co3 o 4 The preparation method of / MXene composite catalyst comprises the following steps:

[0073] Add 2.56g of lithium fluoride powder into 35mL of 8M hydrochloric acid solution, stir magnetically until the solution is clear, and obtain a mixed solution of lithium fluoride and hydrochloric acid; then take 2.56g of MAX phase material (Ti 3 AlC 2 ) powder, under magnetic stirring, slowly add it into the prepared mixed solution of lithium fluoride and hydrochloric acid, heat and stir in an oil bath at 35° C. at a speed of 450 rpm for 96 h. After the stirring is completed, the reaction precipitate is centrifuged and washed 3 times with deionized water (the centrifugal speed is 10000rpm, and the washing time is 20min), until the pH of the centrifuged supernatant is about 6-7, the multilayer MXene can be prepared, and the Sealed for later use. The prepared multi-layer MXene was redispersed with deionized water, shaken and stripped for 60 min, then centrifuged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com