Lithium supplementing slurry as well as preparation method and application thereof

A lithium supplementation and slurry technology, which is applied in the field of lithium supplementation slurry and its preparation, can solve the problems of high price, high safety, and complicated preparation methods, and achieve the effects of low cost, high safety, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

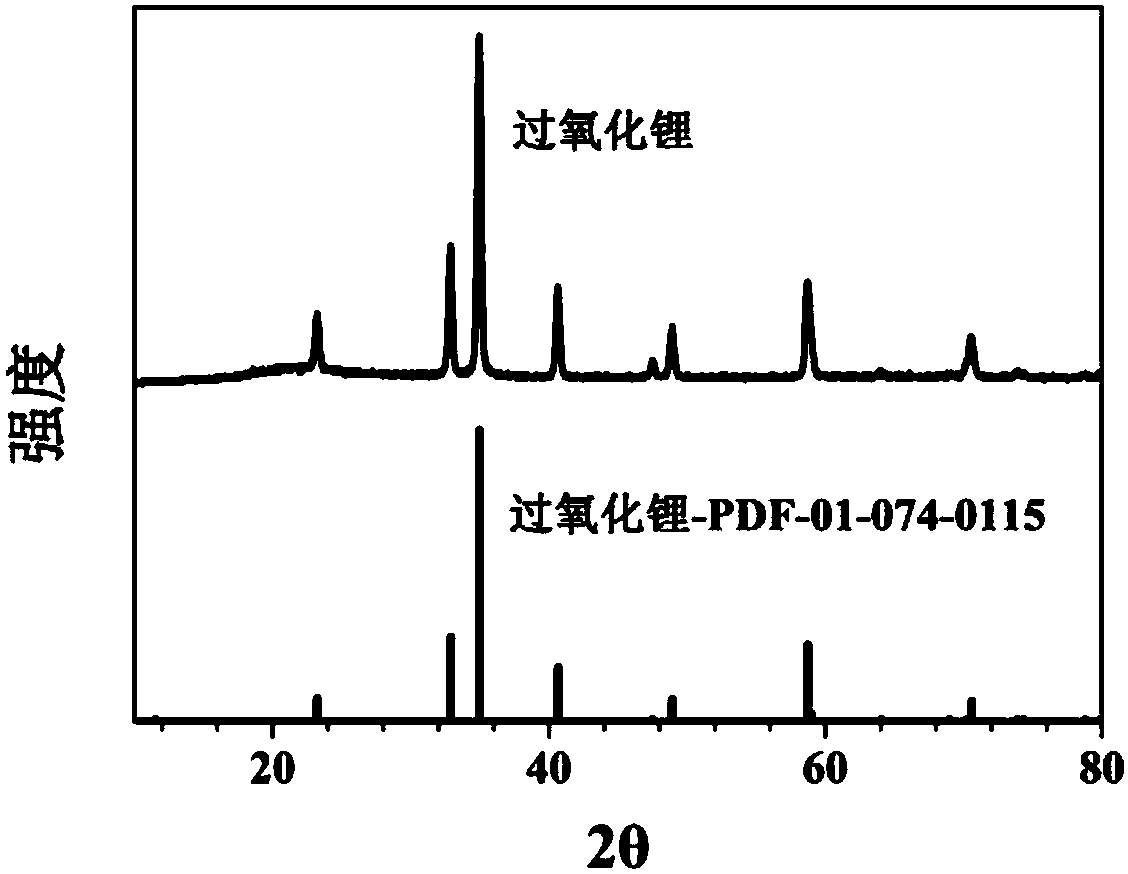

[0030] Preparation of lithium peroxide particles

[0031] Take 21g lithium hydroxide monohydrate (LiOH·H 2 O) be dissolved in 160ml of water, when the dissolution is complete, keep stirring, while slowly adding 70ml of hydrogen peroxide (H 2 o 2 , 30wt%), continue to stir for 30min, add 100ml of ethanol and filter with suction, then vacuum at 150°C for 2h to obtain lithium peroxide.

Embodiment 2

[0033] Preparation of lithium supplement slurry of the present invention

[0034] Get 46g NMP, add 1g polyvinylidene fluoride (PVDF) wherein, keep stirring, until it dissolves completely, add 5g Denka black (Dk) again, keep stirring 30min, finally add the lithium peroxide that 4g embodiment 1 makes, continue Stir for 30 minutes until a slurry is formed, which is recorded as A1.

[0035] Take 35g of NMP, add 0.5g of polyvinylidene fluoride into it, keep stirring until it is completely dissolved, then add 1g of Denka black (Dk), keep stirring for 30min, finally add 3.5g of lithium peroxide prepared in Example 1, and continue stirring for 30min , until the slurry is formed, denoted as A2.

[0036] Take 7g of NMP, add 1g of polyvinylidene fluoride into it, keep stirring until it is completely dissolved, then add 1g of Denkablack (Dk), keep stirring for 30min, finally add 3g of lithium peroxide prepared in Example 1, and continue stirring for 30min until A slurry is formed, denot...

Embodiment 3

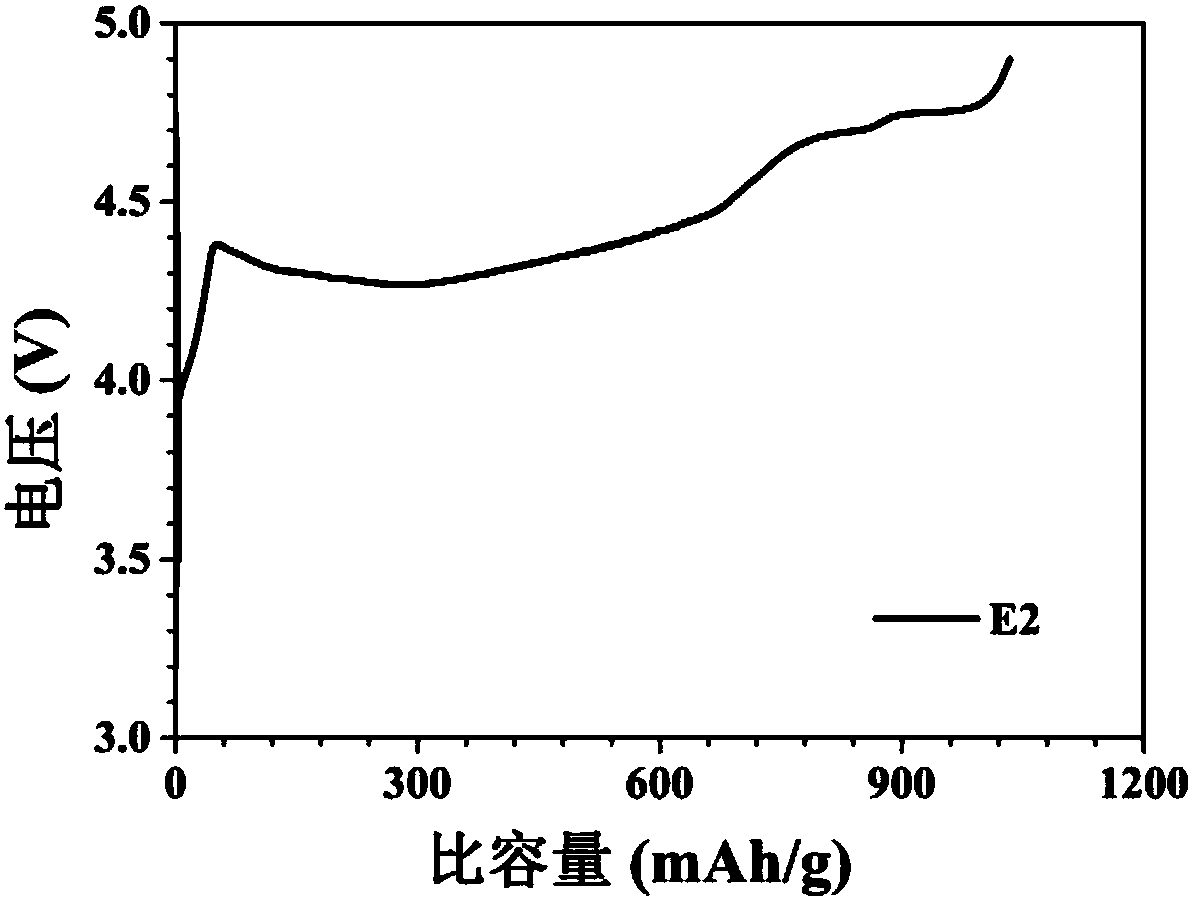

[0041] Preparation of Li 2 o 2 Slurry cathode sheet

[0042] The slurries A1-A6 were evenly coated on the aluminum foil current collector, and dried at 55°C. The pole pieces were cut into discs with a diameter of φ14mm, placed in a vacuum oven at 120°C for 6 hours, and cooled naturally. Take them out and place them in the glove box as the positive pole pieces, which are respectively marked as B1-B6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com