Method for preparing single-crystal ternary positive-electrode material

A positive electrode material, single crystal technology, applied in the field of single crystal ternary positive electrode material preparation, can solve the problems of structural lithium extraction, increased experimental complexity, and many by-product gases, to achieve improved thermal stability and improved electrochemical performance , the effect of increasing capacity and voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

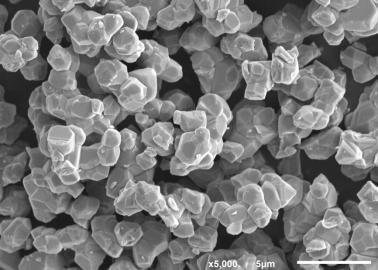

[0028] A method for preparing a single crystal ternary positive electrode material, comprising the following steps:

[0029] S1: Mix lithium oxide with three oxides of nickel, cobalt and manganese in proportion and ball mill; the mass ratio of Li:Ni:Co:Mn is (1.02~1.12):(0.75~0.95):(0.01~0.10): (0.02~0.20), the high nickel content ensures that the capacity of the positive electrode material is high enough. Nickel oxides are NiO, Ni 3 o 4 , NiO 2 、Ni 2 o 3 At least one of the cobalt oxides is Co 3 o 4 、CoO 2 、Co 2 o 3 At least one of the manganese oxides is MnO, Mn 3 o 4 , MnO 2 , Mn 2 o 3 at least one of the During the implementation process, the mass ratio of ball to material used in ball milling is (1~3):1, the speed of ball mill is between 150~250 rpm, and the milling time is 1~4h. The material can be fully mixed evenly, and the particle size of the material after ball milling is 0.5 μm to 3 μm, which is easier to form a new single crystal structure.

[003...

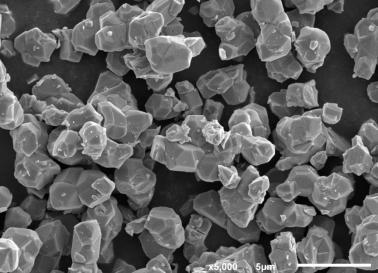

Embodiment 1

[0035] NiO, Co 2 o 3 , Mn 2 o 3 and Li 2 O was mixed and ball milled in proportion; where the molar ratio of Li:Ni:Co:Mn was 1.08:0.84:0.03:0.13. During the implementation process, the mass ratio of ball to material used in the ball mill was 3:1, the speed of the ball mill was 175rpm, and the ball milling time was 3h. The ball-milled product was sintered in an air atmosphere, specifically, the temperature was raised to 490° C. at a rate of 3° C. / min and then kept for 6 hours. Then sinter in an oxygen atmosphere, specifically, the temperature is raised to 750° C. at a rate of 3° C. / min and then kept for 20 hours. Finally, it was naturally cooled to room temperature to obtain a composition of LiNi 0.84 co 0.03 mn 0.13 o 2 single crystal ternary cathode material.

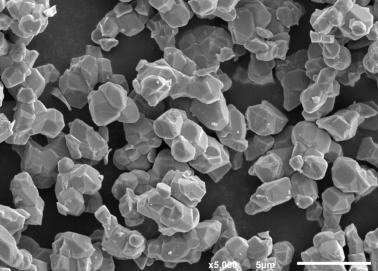

example 2

[0037] NiO, Co 3 o 4 , Mn 3 o 4 and Li 2O was mixed and ball milled in proportion; where the molar ratio of Li:Ni:Co:Mn was 1.06:0.90:0.03:0.07. During the implementation process, the mass ratio of ball to material used in the ball mill was 2.5:1, the rotational speed of the ball mill was 210 rpm, and the ball milling time was 4 hours. The ball-milled product was sintered in an oxygen atmosphere, specifically, the temperature was raised to 550° C. at a rate of 3° C. / min and then kept for 5 hours. Then sintering under an oxygen atmosphere, specifically, the temperature was raised to 730° C. at a rate of 3° C. / min and then kept for 20 hours. Finally, it was naturally cooled to room temperature to obtain a composition of LiNi 0.90 co 0.03 mn 0.07 o 2 single crystal ternary cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com