Patents

Literature

31results about How to "Reduce residual lithium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

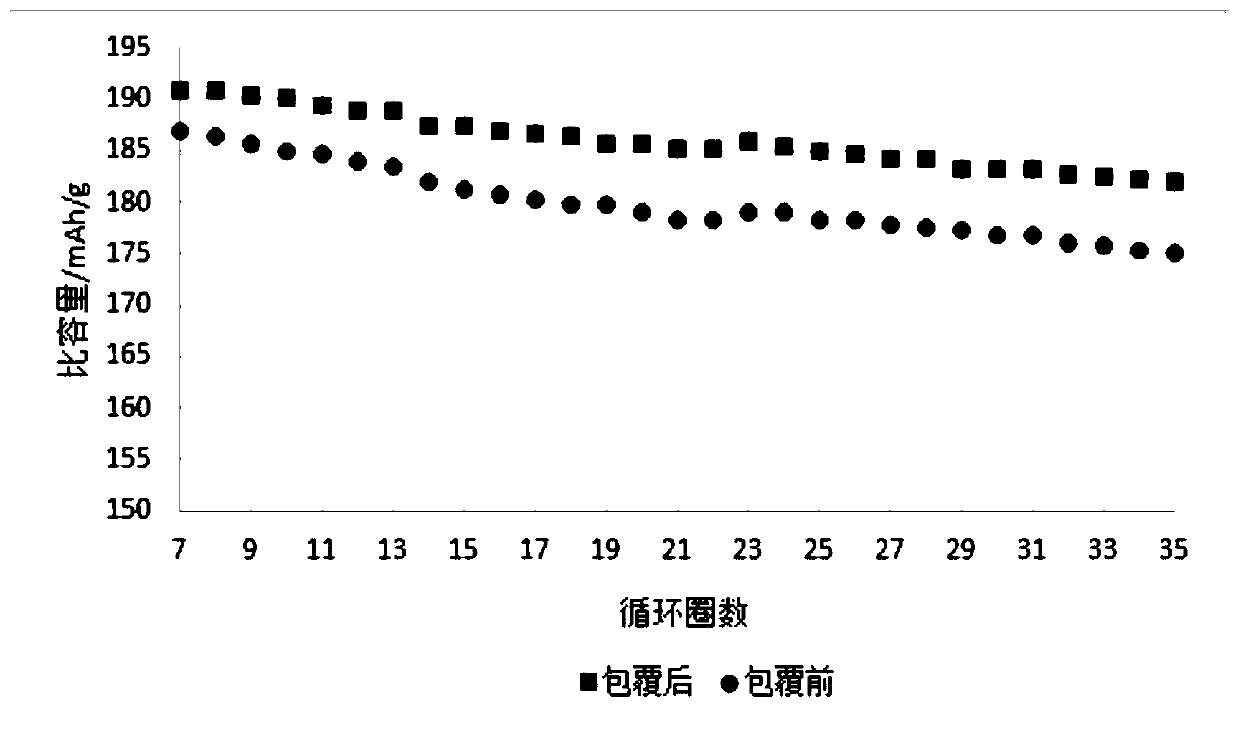

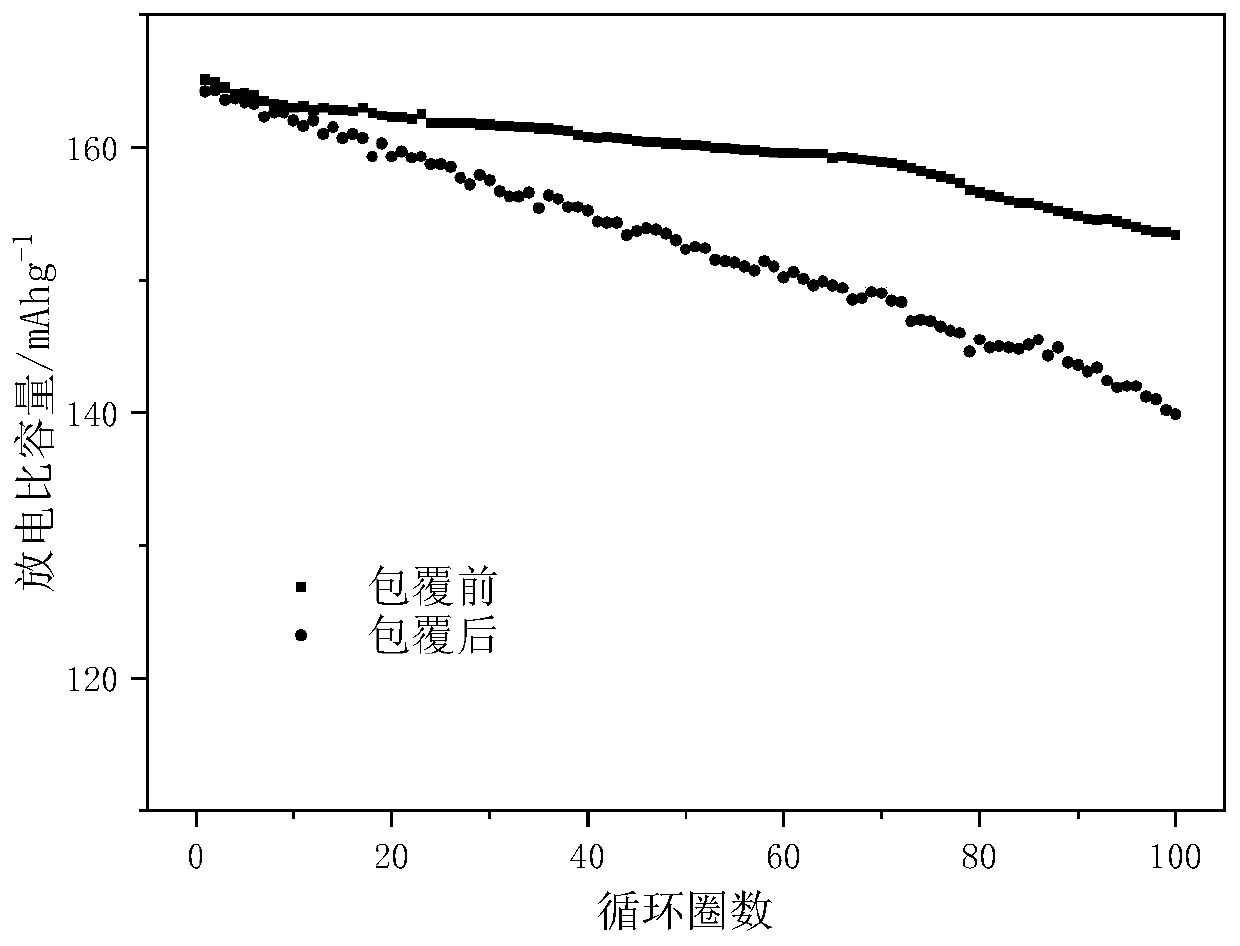

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Lithium nickel cobalt manganate positive electrode material and preparation method thereof

ActiveCN108172822AIncrease energy densityReduce residual lithiumCell electrodesLithium hydroxideManganate

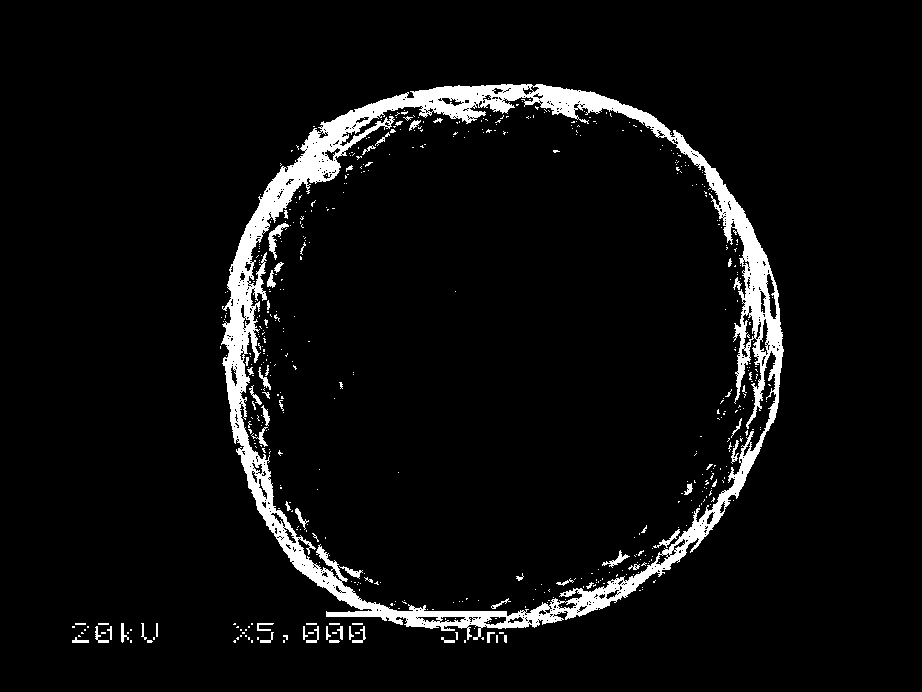

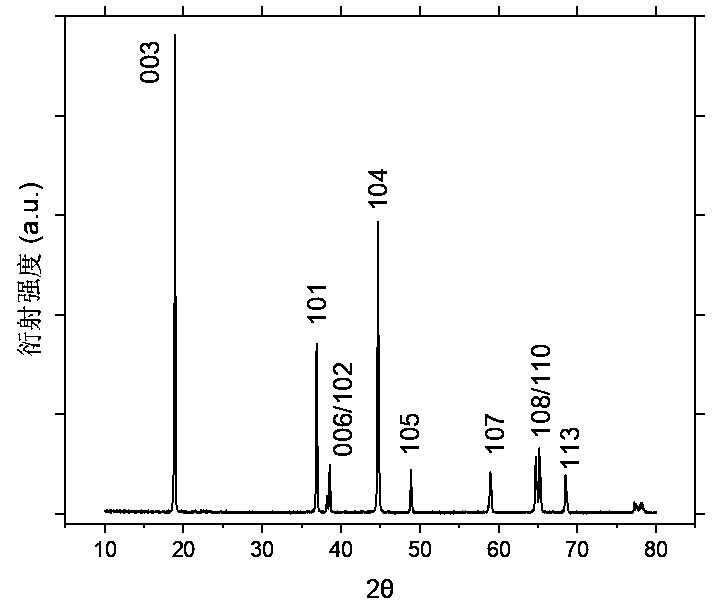

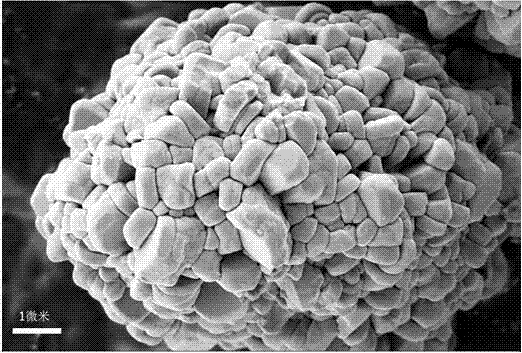

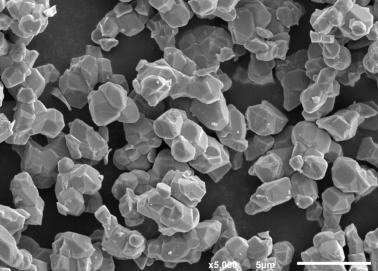

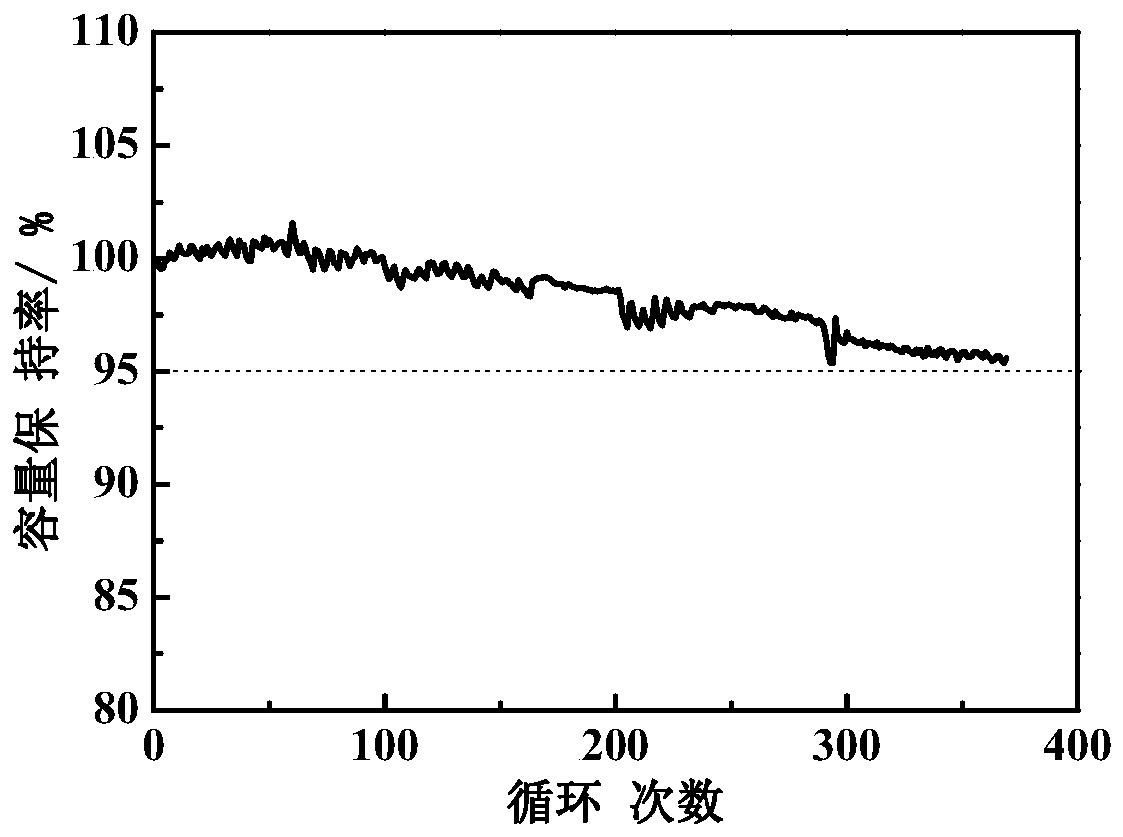

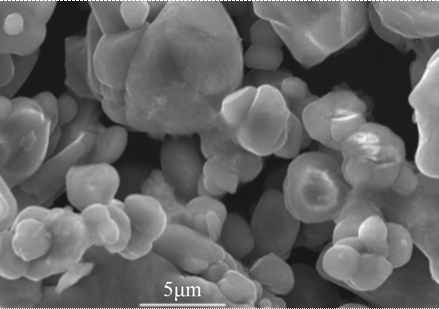

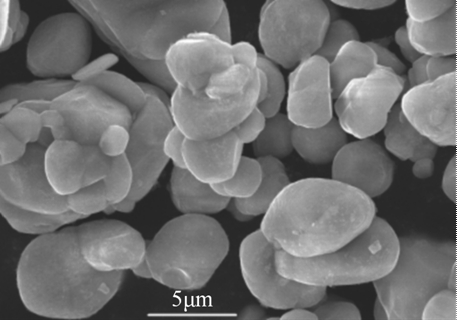

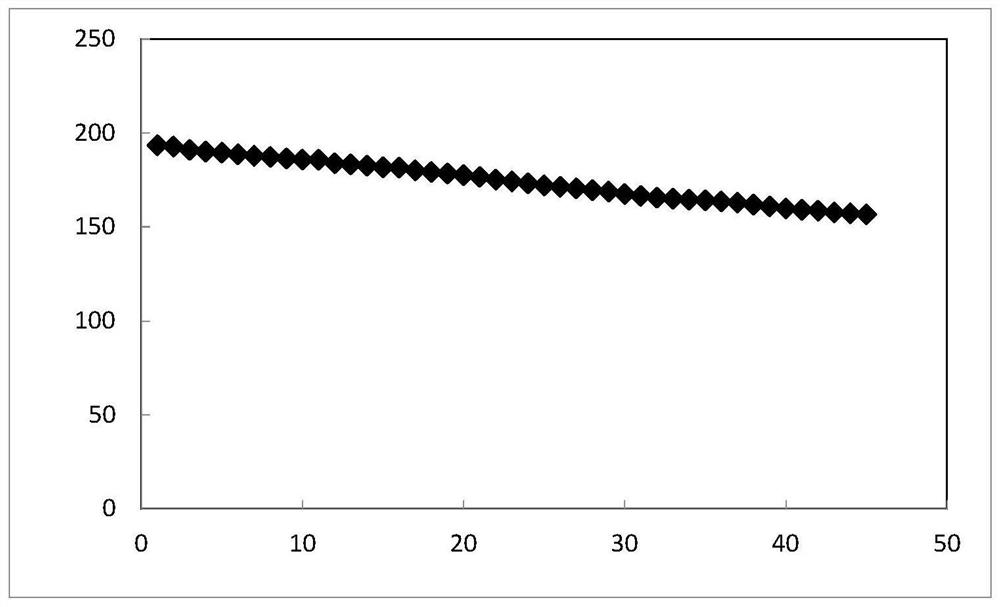

The invention relates to a lithium nickel cobalt manganate positive electrode material and a preparation method thereof. The preparation method comprises the following steps of preparing seed crystalby adopting a hydrothermal method; performing a coprecipitation reaction on the seed crystal to obtain an Ni<x>Co<y>Mn<1-x-y>(OH)<2>, enabling the precursor to be mixed with lithium hydroxide or lithium carbonate at a molar ratio of Li to (Ni+Co+Mn) of 1:1-1.2, and next, performing sintering treatment on the mixture to obtain an intermediate body; enabling the intermediate body to be mixed with lithium hydroxide, and next, spraying metal sol to obtain a pre-coating material; and performing secondary sintering on the pre-coating material to obtain the lithium nickel cobalt manganate positive electrode material. The lithium nickel cobalt manganate positive electrode material prepared by the preparation method has the monocrystal appearance; and the lithium ion battery adopting the positive electrode material is high in energy density which can reach as high as 300wh / kg, and the cycle life can reach 3,000 times.

Owner:ZOLTRIX MATERIAL GUANGZHOU

Preparation method of nickel cobalt lithium aluminate cathode material and lithium ion battery

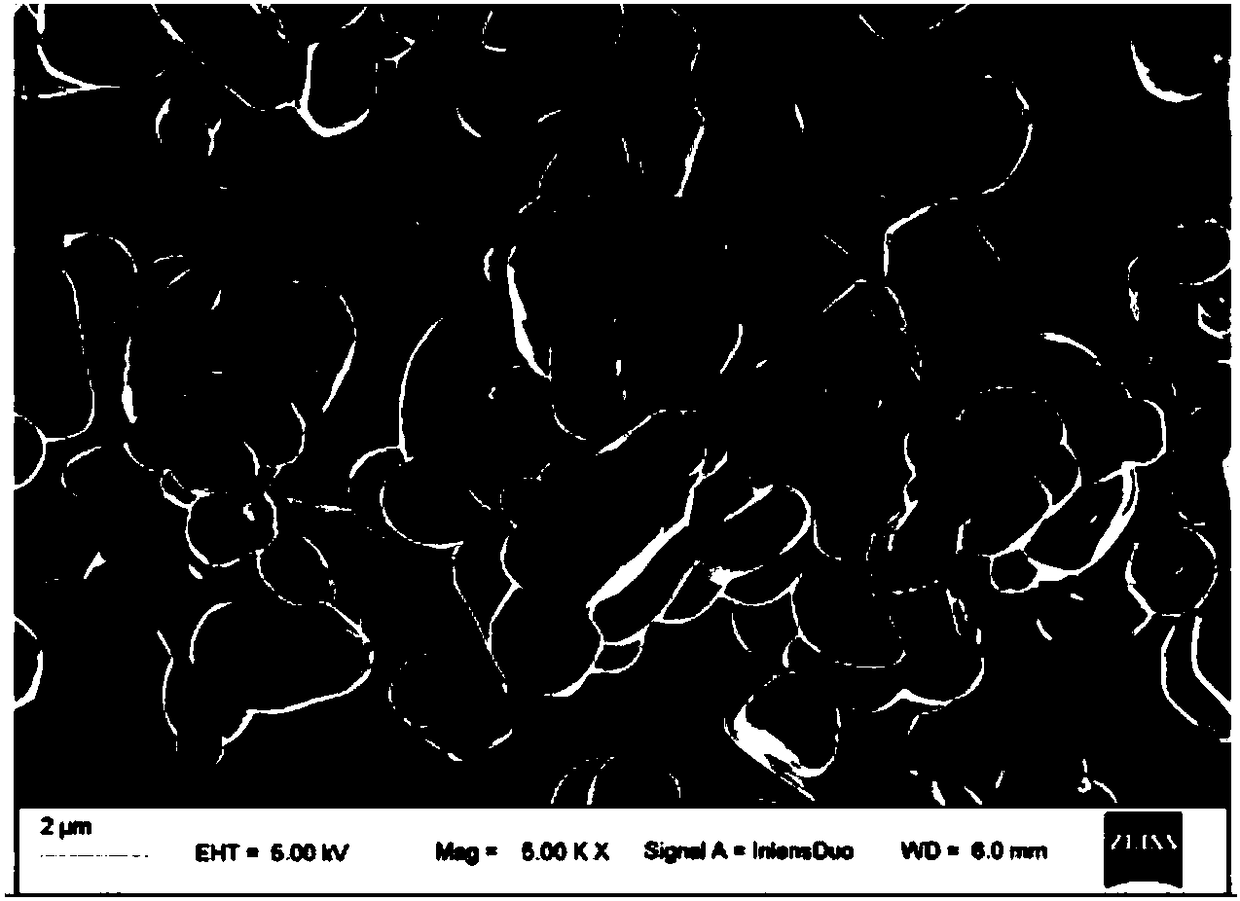

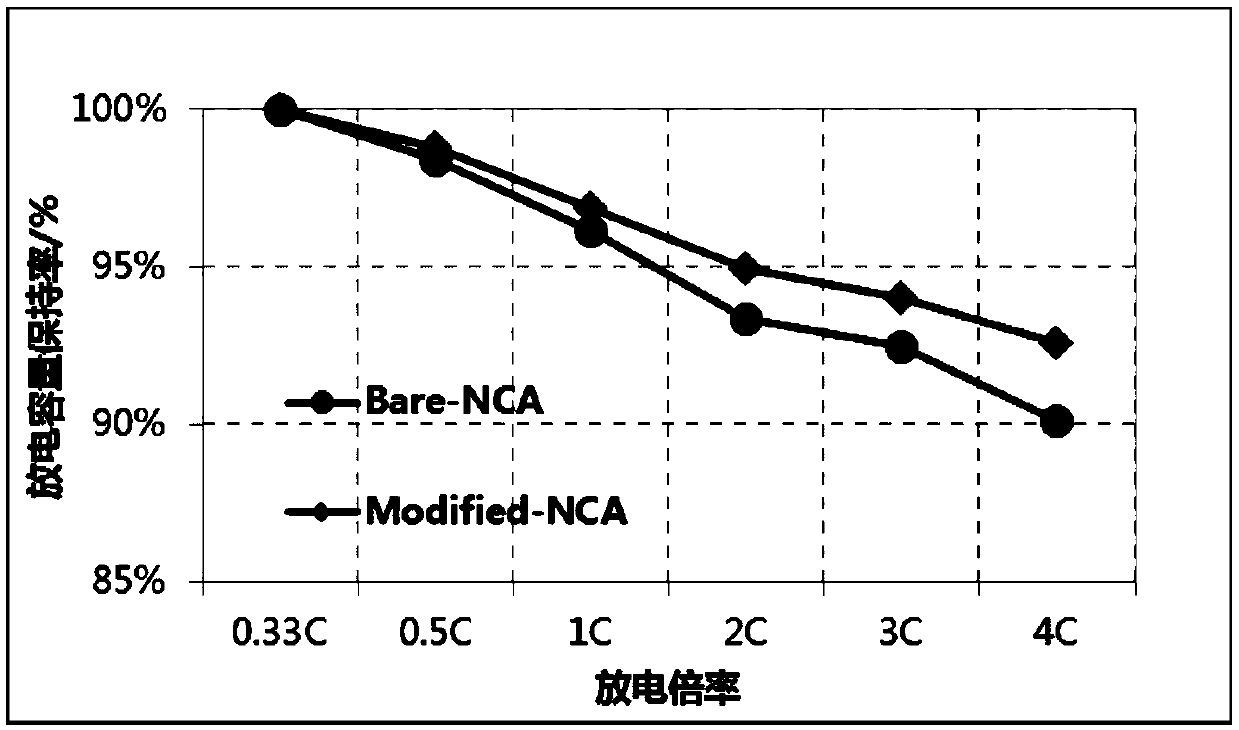

InactiveCN109546101AImproved magnification performanceDoes not hinder migrationCell electrodesSecondary cellsLithium tungstateLithium aluminate

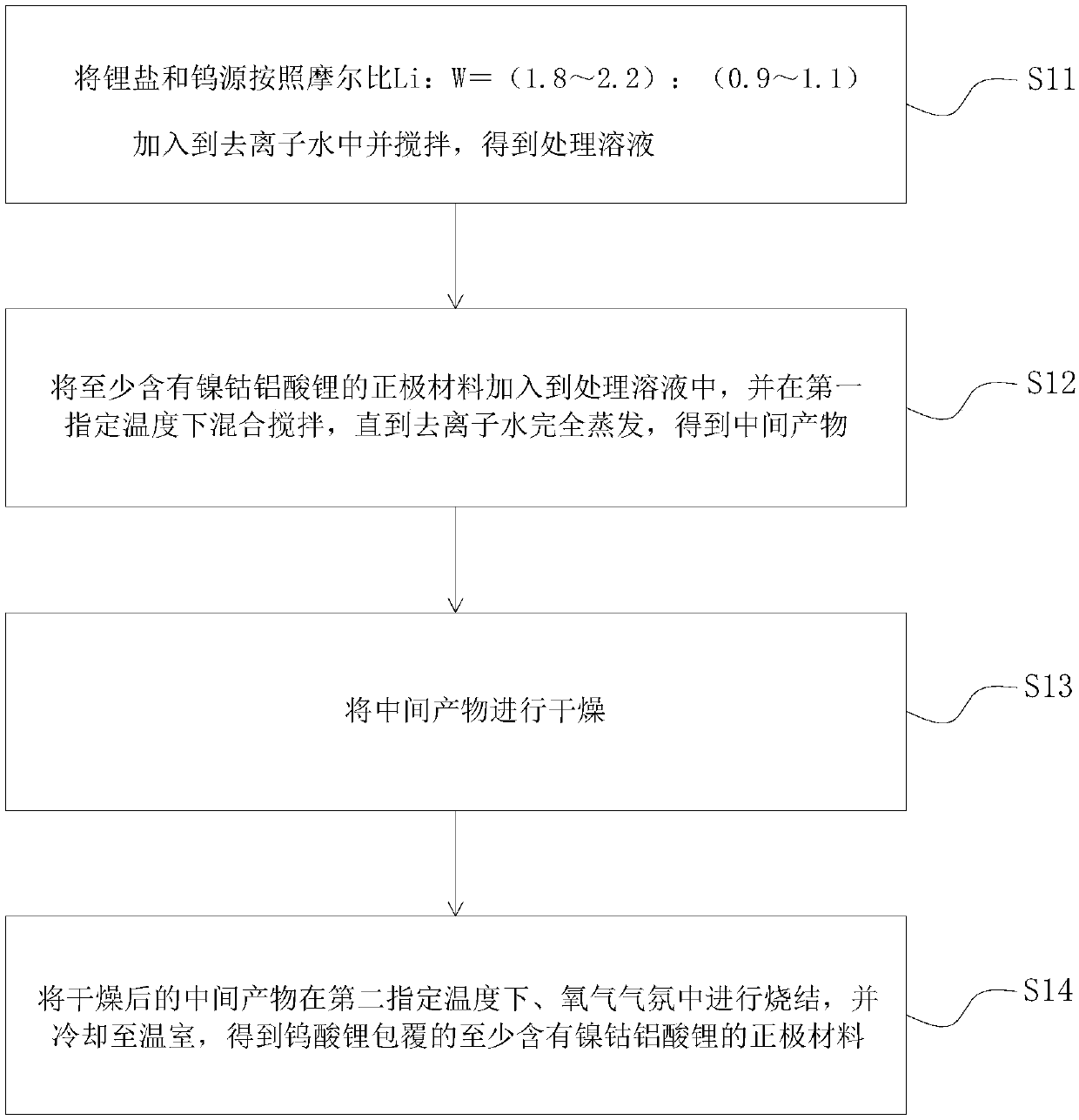

The invention discloses a preparation method of a nickel cobalt lithium aluminate cathode material and a lithium ion battery. The method comprises steps that a lithium salt and a tungsten source are added to the deionized water according to the molar ratio of Li:W=(1.8-2.2):(0.9-1.1) and stirred to obtain a treatment solution; a positive electrode material containing at least nickel cobalt lithiumaluminate is added to the treatment solution, mixed and stirred at the first specified temperature till the deionized water is completely evaporated to obtain an intermediate product; the intermediate product is dried; the dried intermediate product is sintered at the second specified temperature in the oxygen atmosphere and then cooled to the indoor temperature to obtain the positive electrode material containing the at least nickel cobalt lithium aluminate coated with lithium tungstate. The method is advantaged in that the rate, cycle and safety of the nickel cobalt lithium aluminate cathode material can be improved.

Owner:SUNWODA ELECTRONICS

Lithium nickel cobalt manganate composite positive pole material and its preparation method and lithium battery

InactiveCN108269981ASolve the problem of sucking fruit jellyImprove stabilitySecondary cellsPositive electrodesLithium iron phosphateSlurry

The invention relates to a lithium nickel cobalt manganate composite positive pole material and its preparation method and lithium battery and belongs to the technical field of lithium battery materials. The lithium nickel cobalt manganate composite positive pole material comprises lithium nickel cobalt manganate particles and lithium iron phosphate layers on the surfaces of the lithium nickel cobalt manganate particles. The lithium nickel cobalt manganate particles are lithium nickel cobalt manganate secondary particles. The lithium nickel cobalt manganate secondary particles are coated withlithium iron phosphate so that the surface pH of the lithium nickel cobalt manganate material is reduced, the residual lithium on the surface of the material is reduced, the problem that the existinglithium nickel cobalt manganate material adsorbs more water in slurry mixing is solved, the processing properties of the material are improved, the stability of the material during charging and discharging of the battery is improved and the circulation of the battery is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

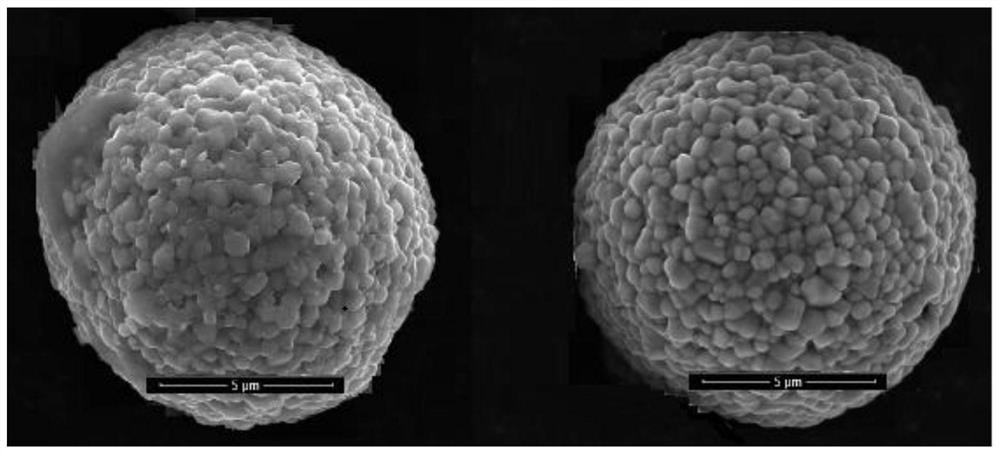

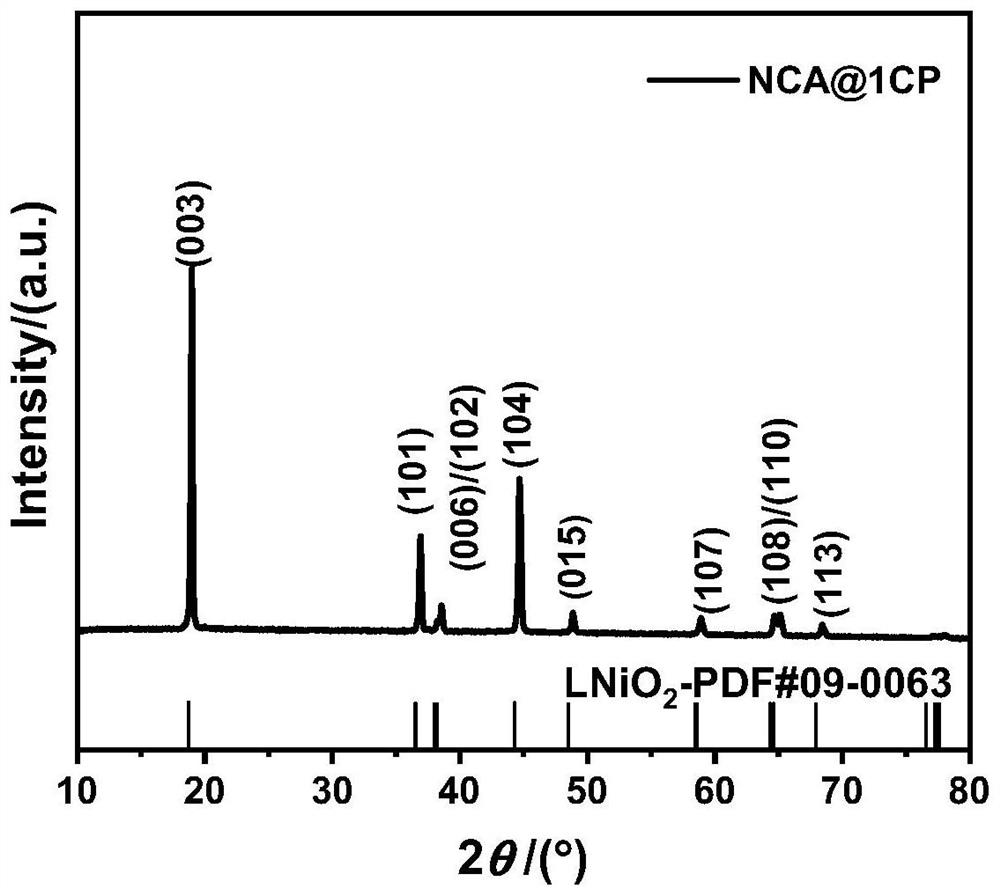

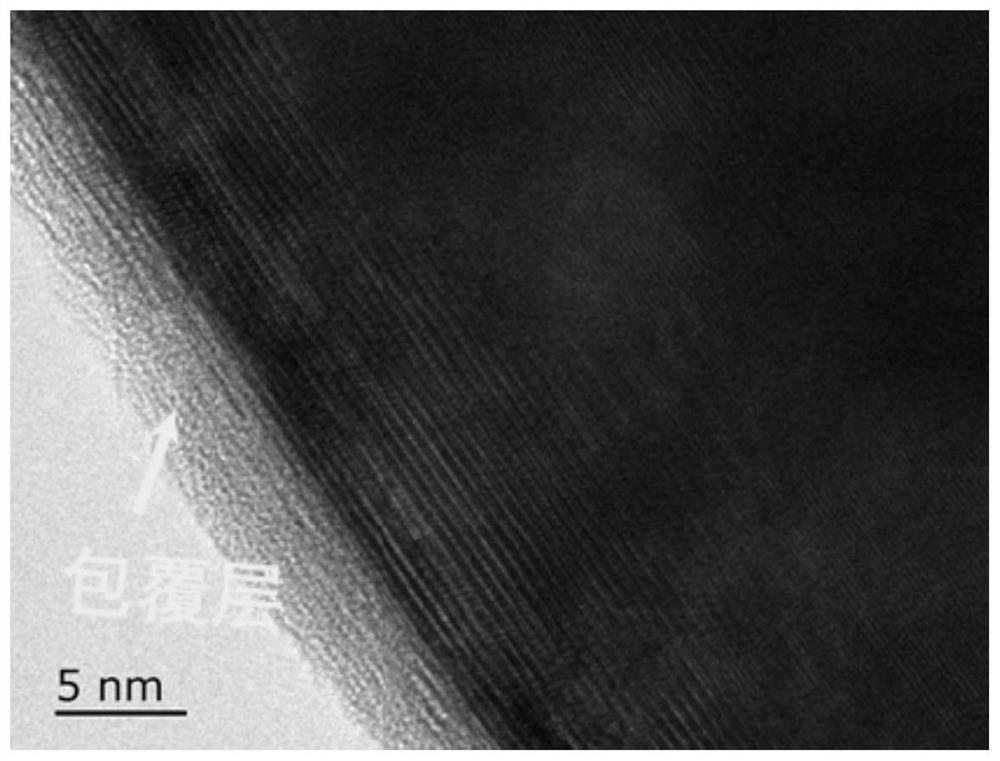

Lithium zirconium phosphate fast ionic conductor coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

ActiveCN109192956AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsElectrical conductorMaterials science

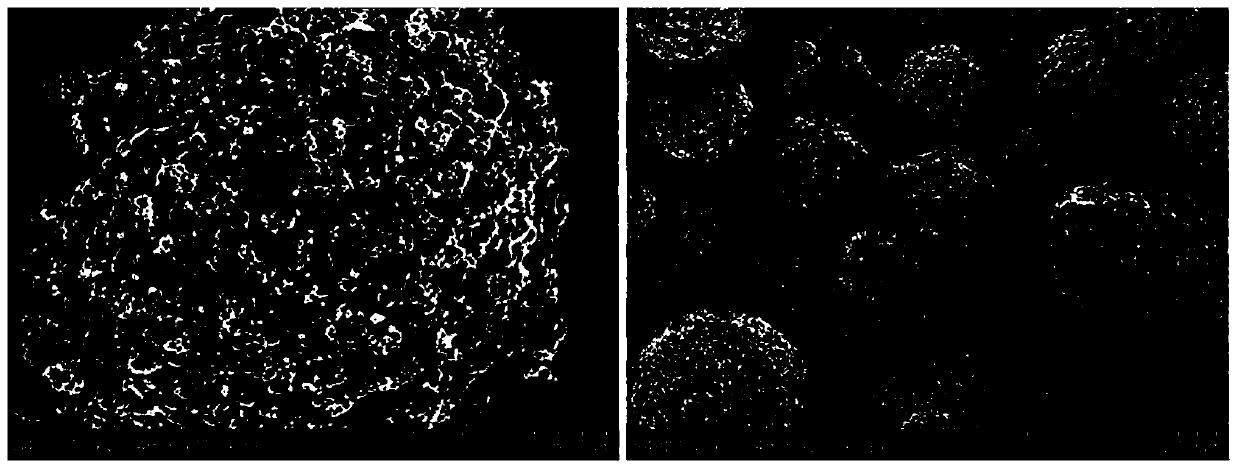

The invention relates to a lithium zirconium phosphate fast ionic conductor coat lithium nickel cobalt aluminate positive electrode material and a preparation method thereof, wherein that mass of thelithium zirconium phosphate fast ionic conductor is 0. 1-10wt%, and the lithium zirconium phosphate fast ionic conductor form a coating layer with a thickness of 5-30nm and is coated on the lithium nickel cobalt aluminate. The positive electrode material is spherical particles with a particle diameter of 5 to 15 mum. The preparation method comprises the following steps: (1) preparing a solution containing phosphorus source and zirconium source, adding zirconium source solution into an organic solvent or water, adding phosphorus source solution, stirring, adding lithium nickel cobalt aluminate,heating and stirring, slowly evaporating and drying, and placing the obtained powder in an oven for drying; (2) placing the powder obtained in the step (1) in a tubular furnace for low-temperature rapid sintering. The positive electrode material of the invention has good cycle stability and rate discharge performance; as that method of the invention can effectively reduce the problem of low circulation stability of the surface residual lithium and ternary materials dure conventional coating, the process cost is low, the process is simple, and the method is suitable for large-scale industrialproduction.

Owner:CENT SOUTH UNIV

High nickel positive electrode material with uniform coating layer and preparation method thereof

InactiveCN109742347ACoated evenlyReduce residual lithiumCell electrodesSecondary cellsWater insolubleLithium metal

The present invention discloses a high-nickel positive electrode material with a uniform coating layer and preparation method thereof. The preparation method comprises following steps: placing a highnickel positive electrode material in water for water washing, adding two or more kinds which can react with each other to generate water-insoluble coating inorganic salt substance, filtering, and rinsing with a low-boiling point organic solvent, pumping out, drying, sintering, cooling, and sieving to obtain a high nickel positive electrode material with the uniform coating layer. Since the coating is coated on surface of an active material through adopting a manner of reacting, stirring, while bonding, the active material can be more uniformly coated; the method reduces residual lithium on the surface of the positive electrode active material while stirring and coating in the water, and provides guarantee on safety and stability for the battery; the method forms a layer of new layered lithium metal oxide structure and a lithium phosphate structure or a lithium sulfate structure on the surface of the positive electrode active material through high temperature sintering, to ensure structural stability of the material while improving a lithium ion migration rate.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Surface coating type ternary positive electrode material and preparation method thereof

ActiveCN106941162AImprove cycle retentionImprove Interface StabilityMaterial nanotechnologyCell electrodesAlkalinityNanoparticle

The invention discloses a surface coating type ternary positive electrode material and a preparation method thereof, and belongs to the technical field of positive electrode materials of lithium ion batteries. The surface coating type ternary positive electrode material includes particles having the molecular formula of LiNi[x]Co[1-x-y]Mn[y]O[2], and the surface of the LiNi[x]Co[1-x-y]Mn[y]O[2] particles is covered with Li2MTiO4 nanoparticles, wherein M is at least one of metal elements of Ni, Co and Mn. A basic crystal phase structure of LiNi[x]Co[1-x-y]Mn[y]O[2] is not damaged, only the surface is coated with the new-phase nanoparticles, the surface protection is formed, and the stability of the interface of the surface of the positive electrode material and an electrolyte solution is increased, so the material circulation maintaining rate is further improved, and the electrochemical performance is enhanced. The surface alkalinity of the positive electrode material is lowered, the hygroscopic property is suppressed, and the processing performance is improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

High-nickel ternary positive electrode material coated with lithium iron phosphate nano-powder and preparation method thereof, and applications

InactiveCN110233249AGood chemical stabilityReduce contact areaCell electrodesSecondary cellsHigh rateLithium iron phosphate

The present invention relates to a high-nickel ternary positive electrode material coated with lithium iron phosphate nano-powder and a preparation method thereof. The preparation method comprises thefollowing steps: (1) mixing a nickel-cobalt-manganese precursor and a lithium source according to a certain lithiation ratio in mixing equipment to obtain a ternary precursor mixer; (2) calcining andgrinding the ternary precursor mixer obtained in step (1); preparing a polyethylene glycol solution, adding the lithium iron phosphate nano-powder into the solution, stirring until a gel is formed, immersing the high-nickel ternary material without being coated with the lithium iron phosphate into the gel, and continuously stirring to obtain a mixer; and (4) drying, allowing the lithium iron phosphate to be coated on the surface of the high-nickel ternary material, sintering the obtained dry material, and grinding to obtain the high-nickel ternary positive electrode material coated with the lithium iron phosphate. The high-nickel ternary positive electrode material coated with the lithium iron phosphate has excellent cycle stability and high rate capability, and thus the material is the potential application material of high-power and long-life lithium batteries.

Owner:WUHAN UNIV OF TECH

High-voltage lithium nickel-cobalt manganate cathode material and preparation method thereof

ActiveCN109786697AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganate

The invention discloses a high-voltage lithium nickel-cobalt manganate cathode material and a preparation method thereof. The lithium nickel-cobalt manganate cathode material is lithium nickel-cobaltmanganate doping material coated with the phosphate, the lithium nickel-cobalt manganate doping material means that the lithium nickel-cobalt manganate doping material is doped with a lanthanum element and a fluorine element; the phosphate is prepared by mixing the aluminum phosphate and diammonium phosphate aqueous solution. The doping of the lanthanum element and the fluorine element can increase the interplanar spacing so as to promote the lithium ion migration and improving the structure stability; the material surface has good lithium ion conductivity feature and a certain electronic conductivity feature by coating the phosphate on the surface, so that the material has higher lithium-removing state stability under high voltage; the residual lithium quantity of the material surface isreduced, the surface side reaction is inhibited, and the structure stability and the cycle performance of the material under high voltage are obviously improved.

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

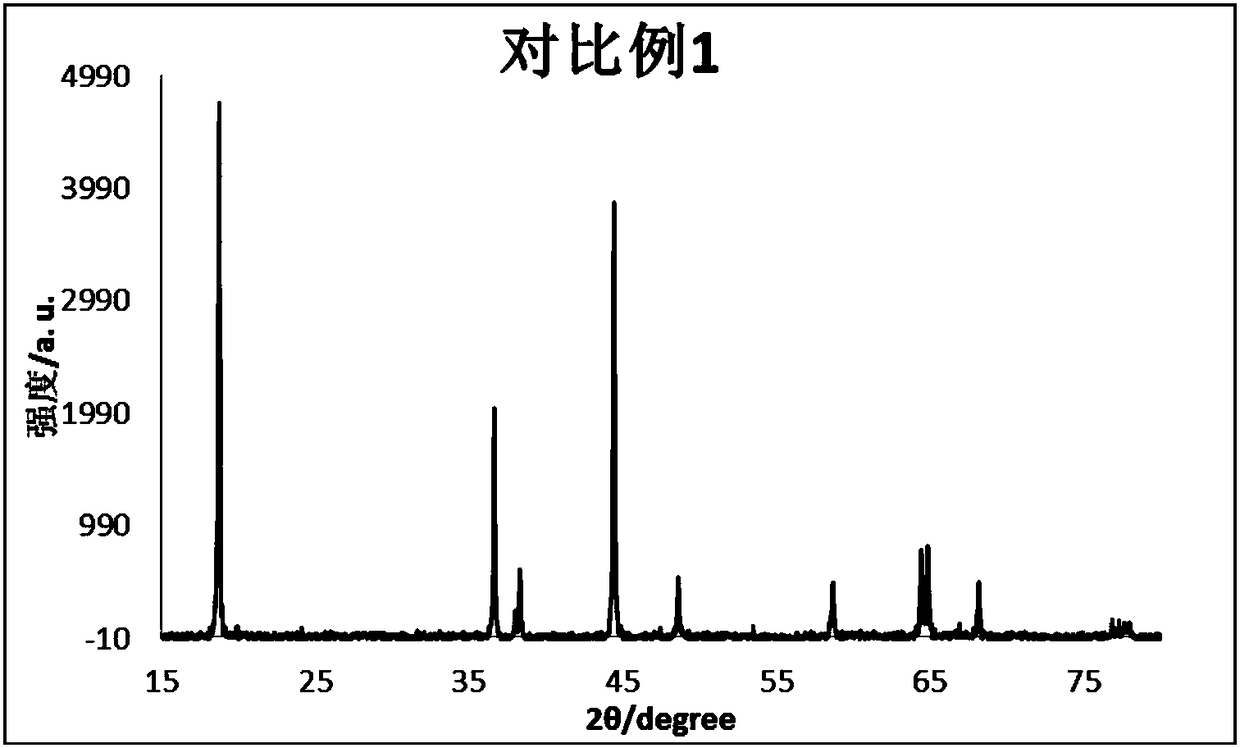

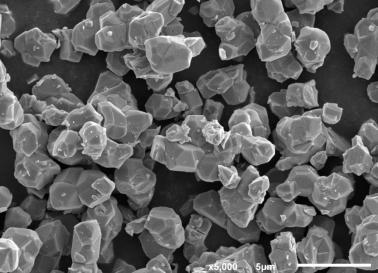

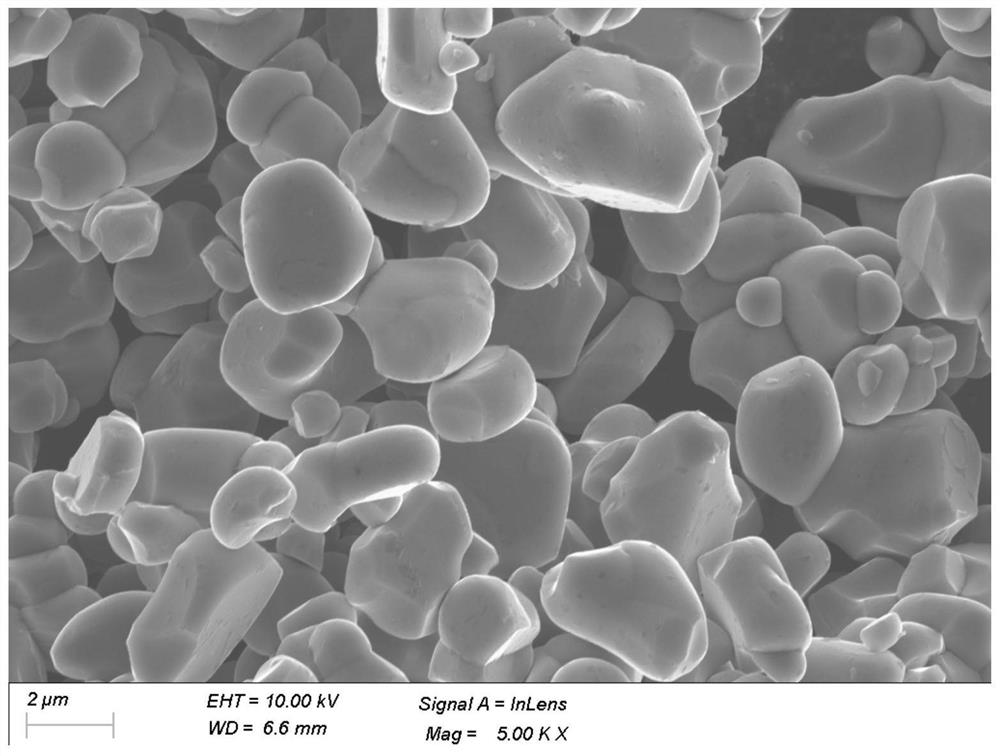

Method for preparing single-crystal ternary positive-electrode material

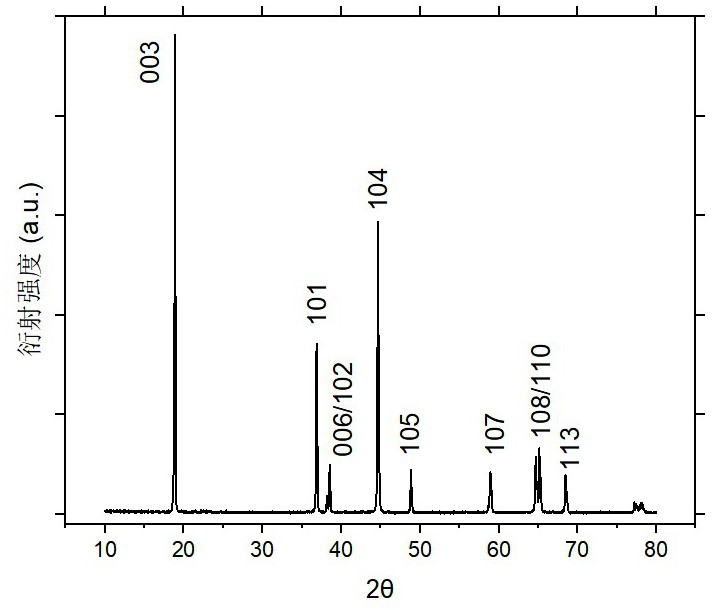

ActiveCN109279659AImprove consistencyImprove stabilityCell electrodesSecondary cellsLithium oxideLithium peroxide

The invention discloses a method for preparing a single-crystal ternary positive-electrode material, belonging to the technical field of lithium ion batteries. The method comprises the following steps: subjecting lithium oxide and the oxides of nickel, cobalt and manganese in a certain ratio to mixing and ball milling; performing primary sintering on a ball-milled material at 400-600 DEG C; carrying out secondary sintering on a product obtained after primary sintering at 650-780 DEG C; and finally, performing natural cooling to room temperature so as to obtain the single-crystal ternary positive-electrode material. The method of the invention directly adopts the oxides as raw materials and avoids the phenomenon of gas generation when hydroxides or carbonate compounds are used as raw materials, so the consistency of an atmosphere, the stability of heat and structural cracking are greatly improved; through direct mixing of the lithium oxide with the oxides of nickel, cobalt and manganese, uniform mixing is realized, the particle size of a sintering raw material is small, and all the elements are uniformly mixed, so a condition for forming a single crystal at a lower temperature is provided.

Owner:CNGR ADVANCED MATERIAL CO LTD

Garnet-type ion conductor-coated high-nickel ternary positive electrode material, preparation method and lithium ion battery obtained by preparation

InactiveCN109904427AImprove ionic conductivityReduce residual lithiumCell electrodesSecondary cellsElectrical conductorCrystal structure

The invention discloses a garnet-type ion conductor-coated high-nickel ternary positive electrode material, a preparation method and a lithium ion battery obtained by preparation. A matrix of the garnet-type ion conductor-coated high-nickel ternary positive electrode material is LiNi<1-x-y>Co<x>Mn<y>O<2-z>Ha<z>, wherein x is more than 0 but less than or equal to 0.15, y is more than 0 but less than or equal to .15, z is more than 0 or less than or equal to 0.04, Ha is one or more of F, Cl, Br, the chemical formula of a garnet-type ion conductor is one or more of Li<7-a>La<3>Zr<2-a>MaO<12>, Li5La3M2O12, Li<5.5>La<3>M<1.75>A<0.25>O<12>, Li6DLa2M2O12, Li<7.06>M<3>Y<0.06>Zr<1.94>O<12> and Li<7.06>La<3>Y<0.06>Zr<1.94>O<12>, M is Nb or Ta, A is In or Zr, D is Ca, Sr or Ba, and a is more than orequal to 0 but less than or equal to 1. By direct mixing and coating of a garnet-type coating agent and the ternary material, a sintering temperature is lower than 700 DEG C, the damage to a crystal structure of the ternary lithium nickel-cobalt manganate material is prevented, and the rate performance and the cycle performance of a lithium ion battery are improved.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

Phosphate-coated lithium cobalt oxide positive electrode material and preparation method thereof

ActiveCN113346066AAvoid reactionImproved magnification performanceSecondary cellsPositive electrodesElectrolytic agentElectrical conductor

The invention belongs to the field of battery materials, and particularly discloses a multi-metal phosphate coated lithium cobalt oxide positive electrode material and a preparation method thereof. According to the invention, the surface of the lithium cobalt oxide positive electrode material substrate is creatively coated with the multi-metal phosphate layer. The preparation method comprises the following steps: adding a prepared metal salt solution and a high-molecular compound into pure water for reaction, adding a lithium cobalt oxide aqueous solution after dispersion, and heating while stirring to form gel; uniformly mixing the gel, and adding the gel into a mechanical fusion compaction machine to complete material coating; and finally, quickly and efficiently sintering at a relatively low temperature, and naturally cooling along with the furnace to obtain the multi-metal phosphate coated lithium cobalt oxide positive electrode material. The coating layer on the surface of the matrix of the lithium cobalt oxide positive electrode material is a fast ion conductor, so that the rate capability of the material can be improved; the reaction between the electrode and the electrolyte can be prevented, and the capacity fading of the lithium cobalt oxide material is slowed down; and meanwhile, the residual lithium amount of the finished product can be effectively reduced, and the storage performance of the finished product is improved.

Owner:HUNAN CHANGYUAN LICO CO LTD +2

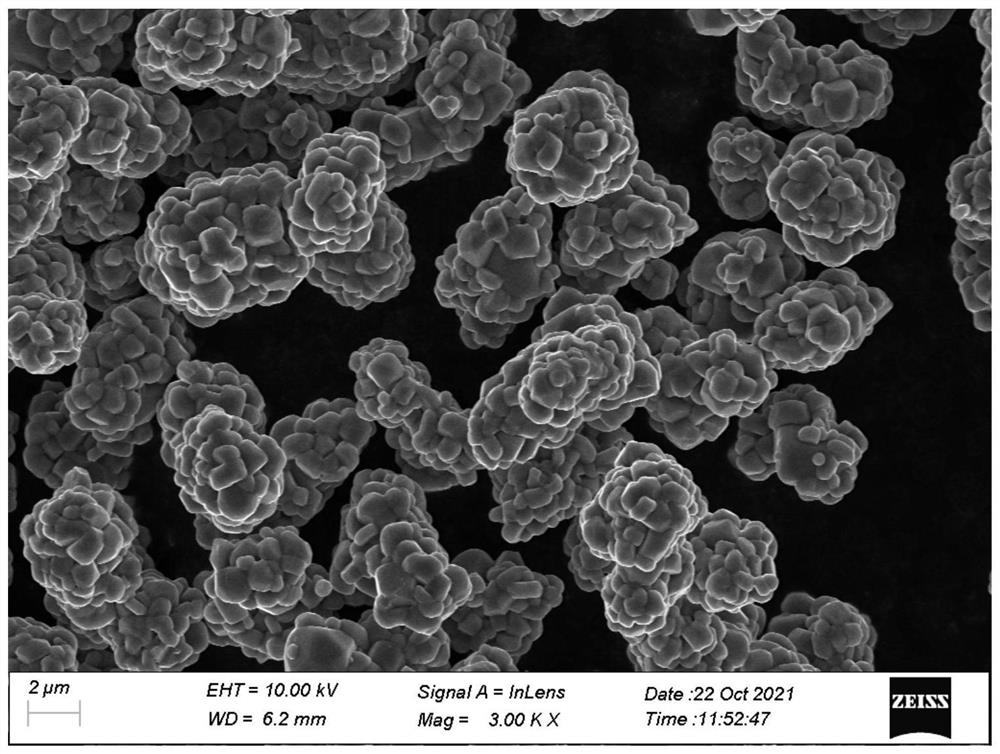

High-power long-circulation nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

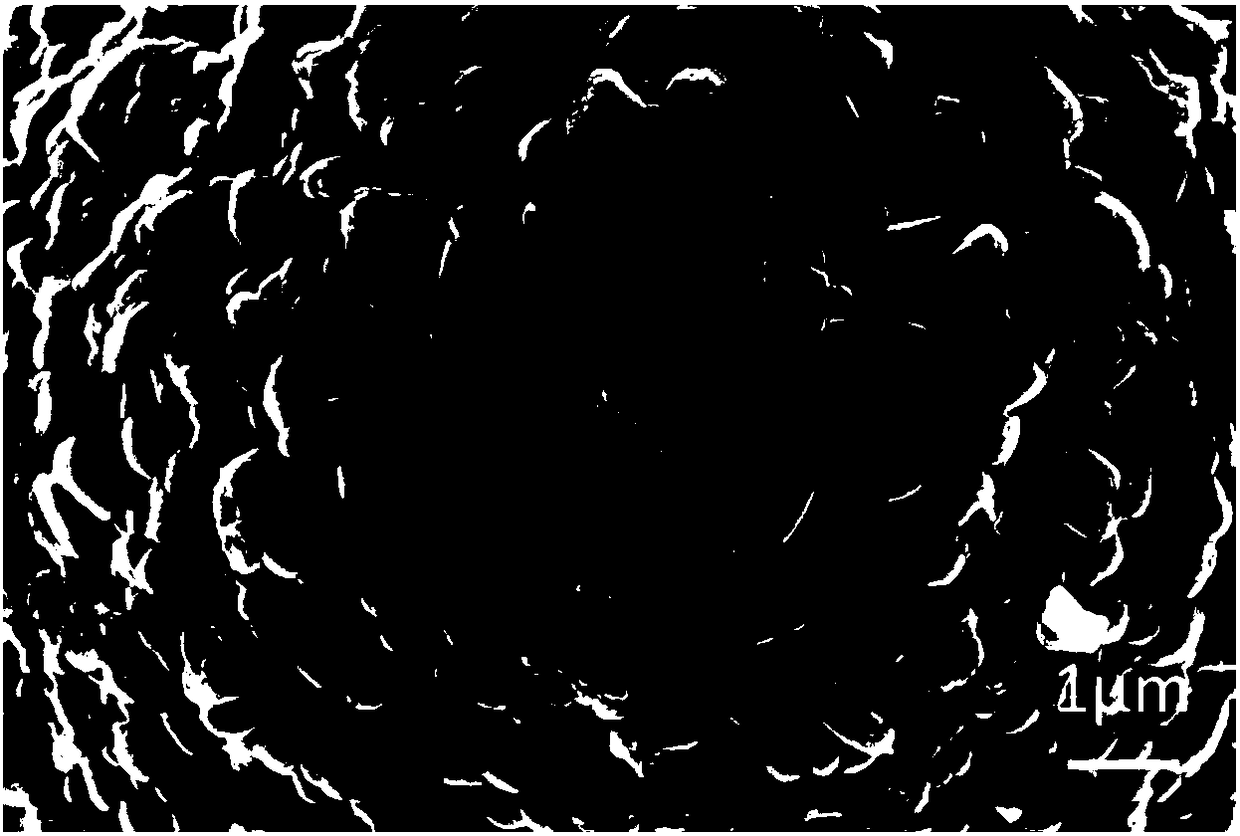

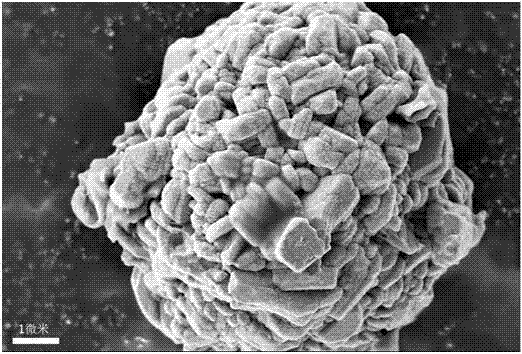

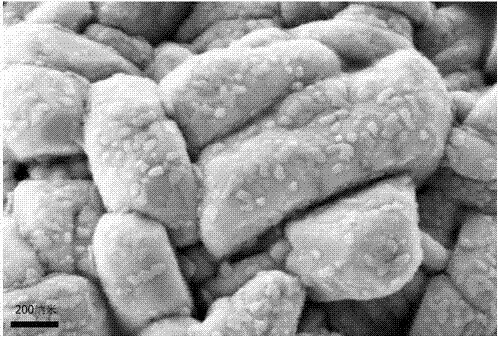

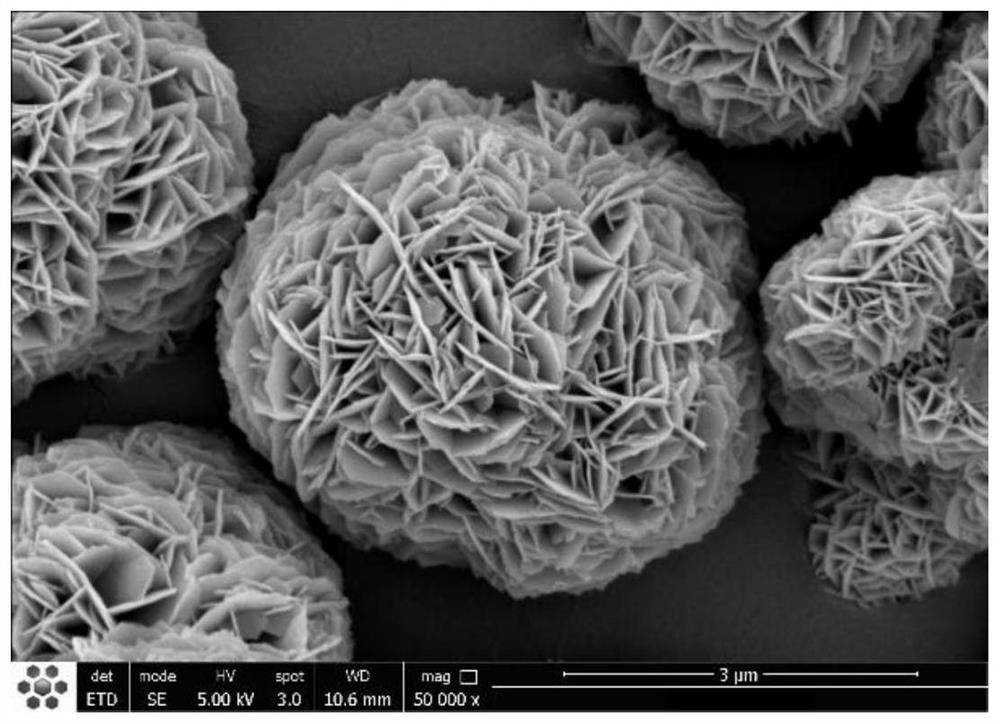

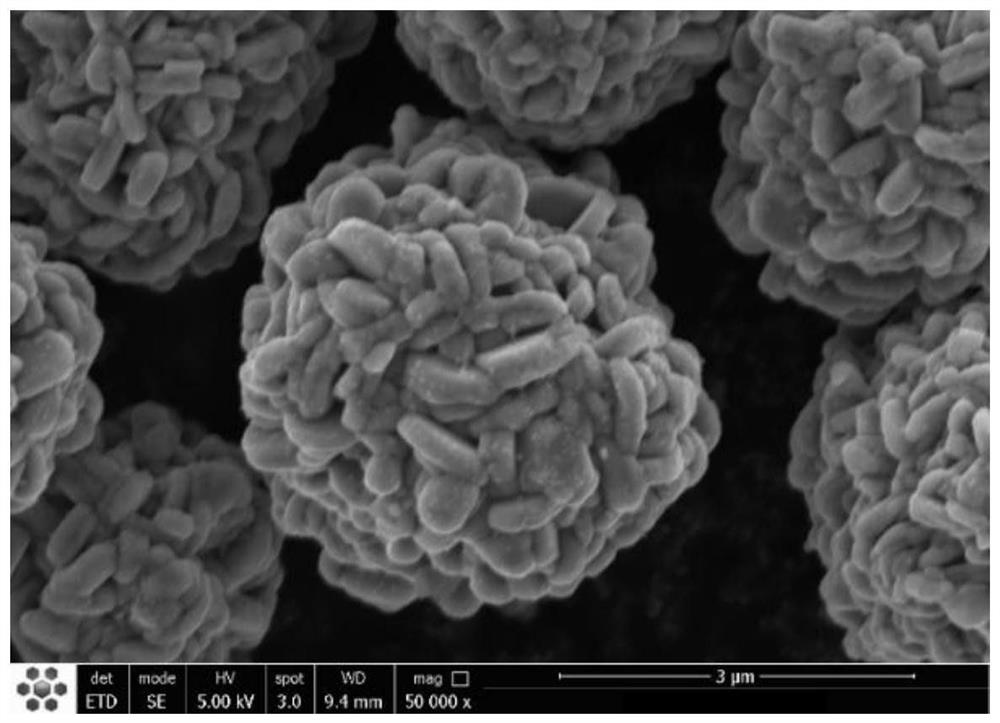

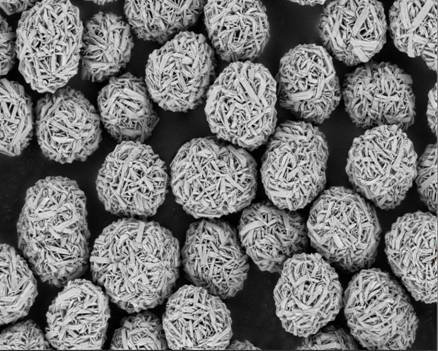

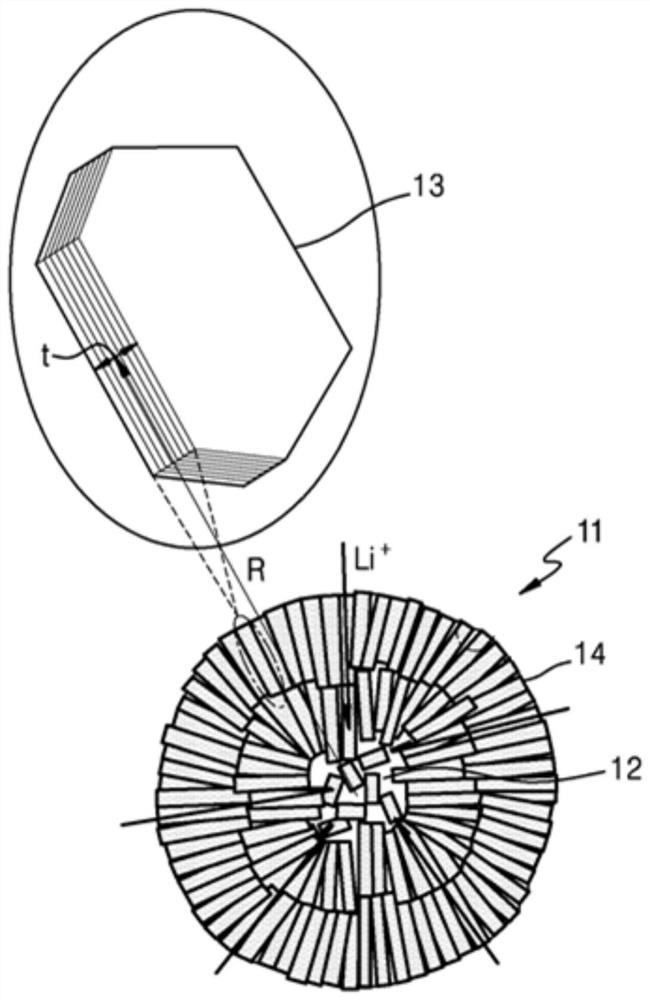

PendingCN114824196AShorten the transmission distanceIncreased diffusion rateSecondary cellsPositive electrodesLithiumDopant

The invention provides a high-power long-circulation nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof, the high-power long-circulation nickel-cobalt-manganese ternary positive electrode material is composed of secondary particles, and the primary particles forming the secondary particles are strip-shaped; the D50 particle size of the secondary particles is controlled to be 2.0-5.0 [mu] m, the secondary particles are of an inner hollow structure, the outer wall thickness d1 of the secondary particles is 0.3-1.1 [mu] m, the wall-to-pore ratio R of the secondary particles is 0.1-0.7, and the wall-to-pore ratio R is equal to d1 / (D50-2d1). The preparation method comprises the following steps: S1, synthesizing a nickel-cobalt-manganese hydroxide precursor by adopting a coprecipitation method, and growing and forming a layer of compact shell on the surface of a loose inner core; s2, mixing the precursor, a lithium salt and a dopant, and sintering after uniform mixing; and S3, crushing and dissociating the sintered product, mixing with the coating, and sintering after uniformly mixing. By controlling the wall-to-pore ratio, the morphology and the primary particle arrangement mode, the processing performance of the material is improved, meanwhile, high power and long cycle performance can be considered, and the performance requirements of HEV type batteries are met.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

A kind of phosphate-coated lithium cobalt oxide cathode material and preparation method thereof

ActiveCN113346066BAvoid reactionImproved magnification performanceSecondary cellsPositive electrodesElectrolytic agentElectrical conductor

The invention belongs to the field of battery materials, and specifically discloses a polymetallic phosphate-coated lithium cobaltate positive electrode material and a preparation method thereof. The invention creatively coats a polymetallic phosphate layer on the surface of a lithium cobaltate positive electrode material matrix to prepare The method is as follows: Add the prepared metal salt solution and polymer compound in pure water to react, then add lithium cobaltate aqueous solution after dispersion, stir and heat at the same time to form a gel; mix the gel evenly and add it to a mechanical fusion compactor The coating of the material is completed in the process; finally, the lithium cobalt oxide cathode material coated with polymetallic phosphate is obtained after rapid and efficient sintering at a lower temperature and then natural cooling with the furnace. The cladding layer on the surface of the lithium cobaltate positive electrode material of the present invention is a fast ion conductor, which can improve the rate performance of the material; it can also prevent the reaction between the electrode and the electrolyte, and slow down the capacity fading of the lithium cobaltate material; at the same time, the present invention The advanced technology can effectively reduce the amount of residual lithium in the finished product and improve its storage performance.

Owner:HUNAN CHANGYUAN LICO CO LTD +2

Lithium hydroxide monohydrate, preparation method and application thereof, lithium ion battery positive electrode material and lithium ion battery

ActiveCN110817904AHigh purityLow magnetic element contentLithium oxides/hydroxidesPhysical chemistryLithium-ion battery

The present disclosure relates to lithium hydroxide monohydrate, a preparation method and application thereof, a lithium ion battery positive electrode material and a lithium ion battery. The lithiumhydroxide monohydrate has a particle size of 100-380 nm, and by weight, the content of Cu in the lithium hydroxide monohydrate is less than 1ppm, the content of Cr is less than 1ppm, the content of Niis less than 2ppm, the content of Zn is less than 2ppm, and the content of Fe is less than 4 ppm. The lithium hydroxide monohydrate has low magnetic element content, and can improve the service lifeof the lithium ion battery and reduce the self-discharge effect of the lithium ion battery when being used for preparing the lithium ion battery positive electrode material.

Owner:BYD CO LTD

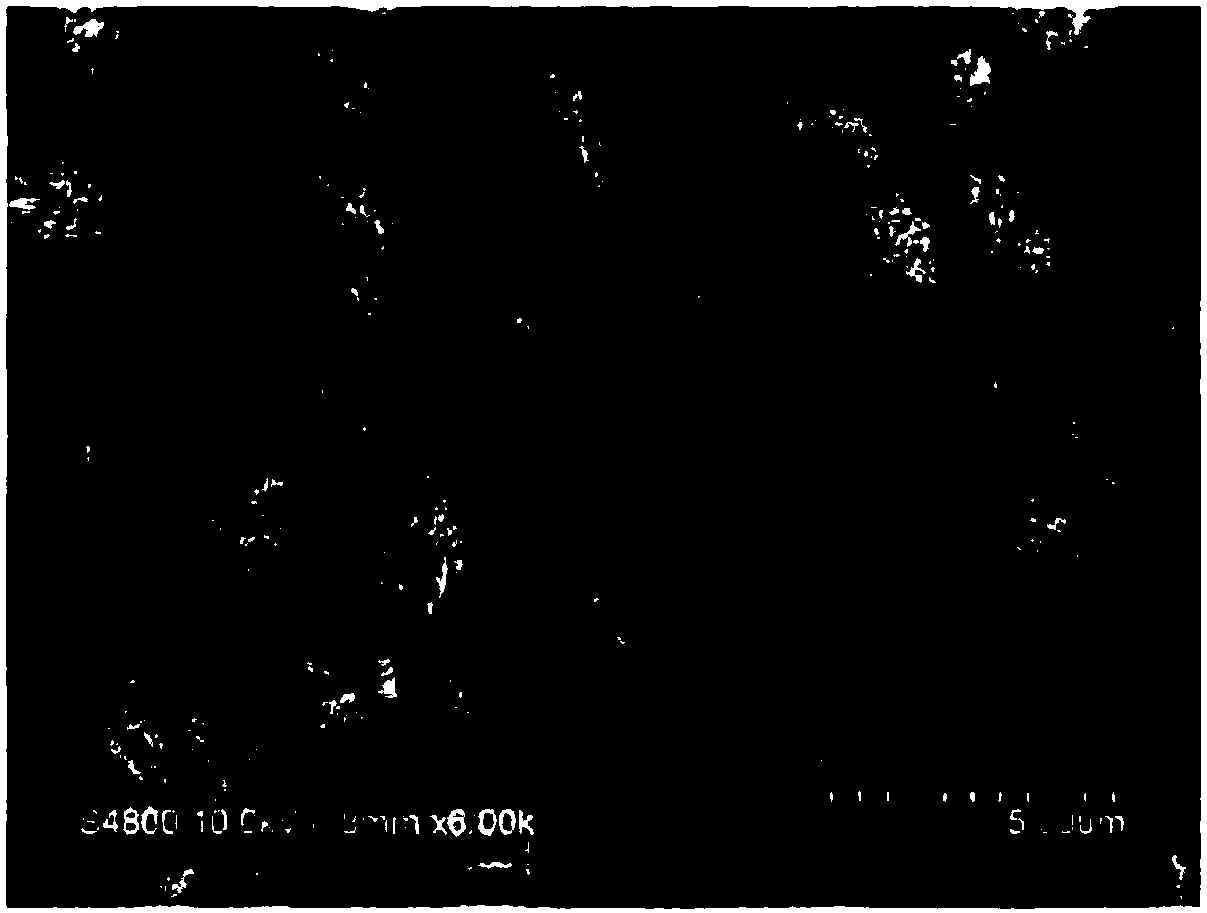

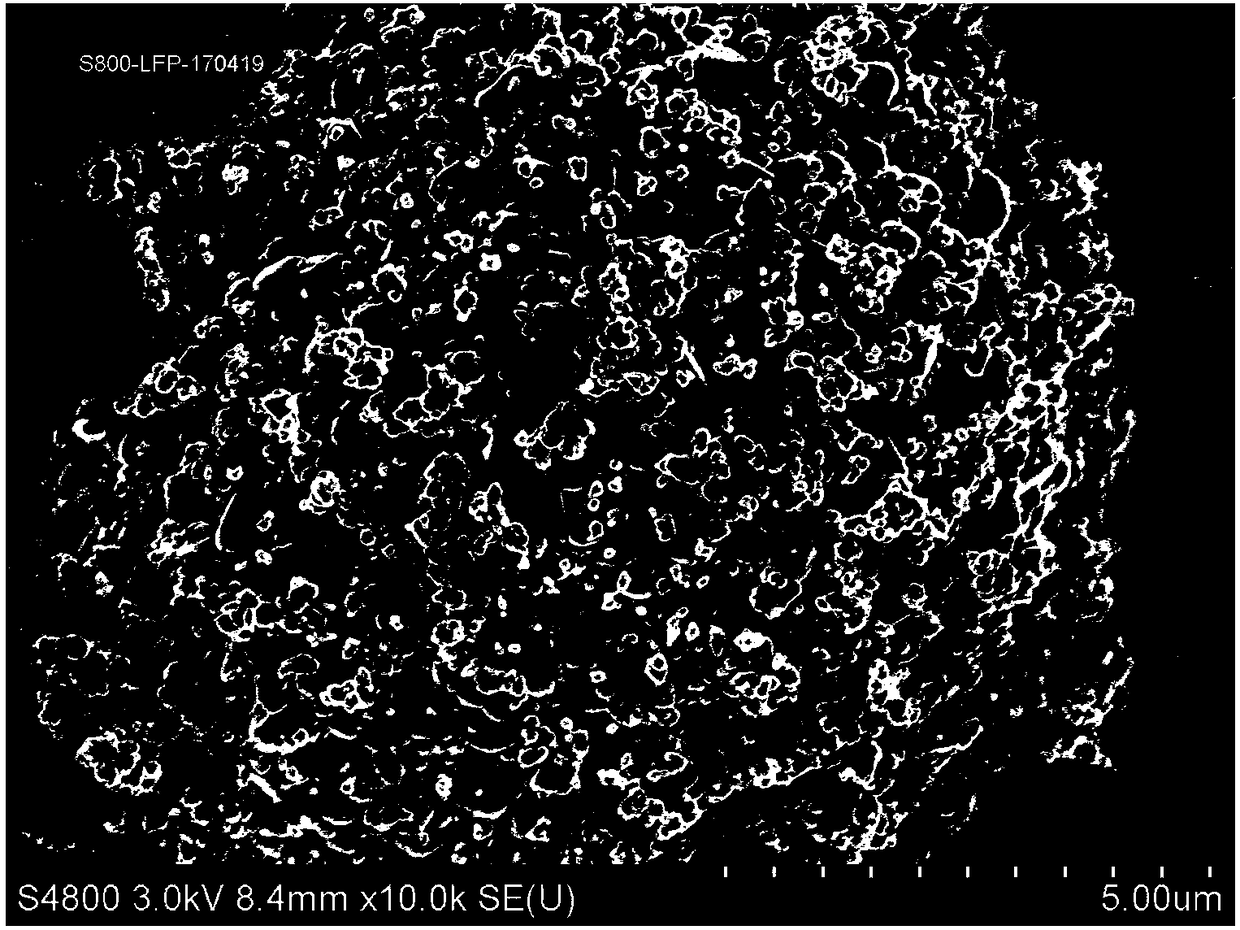

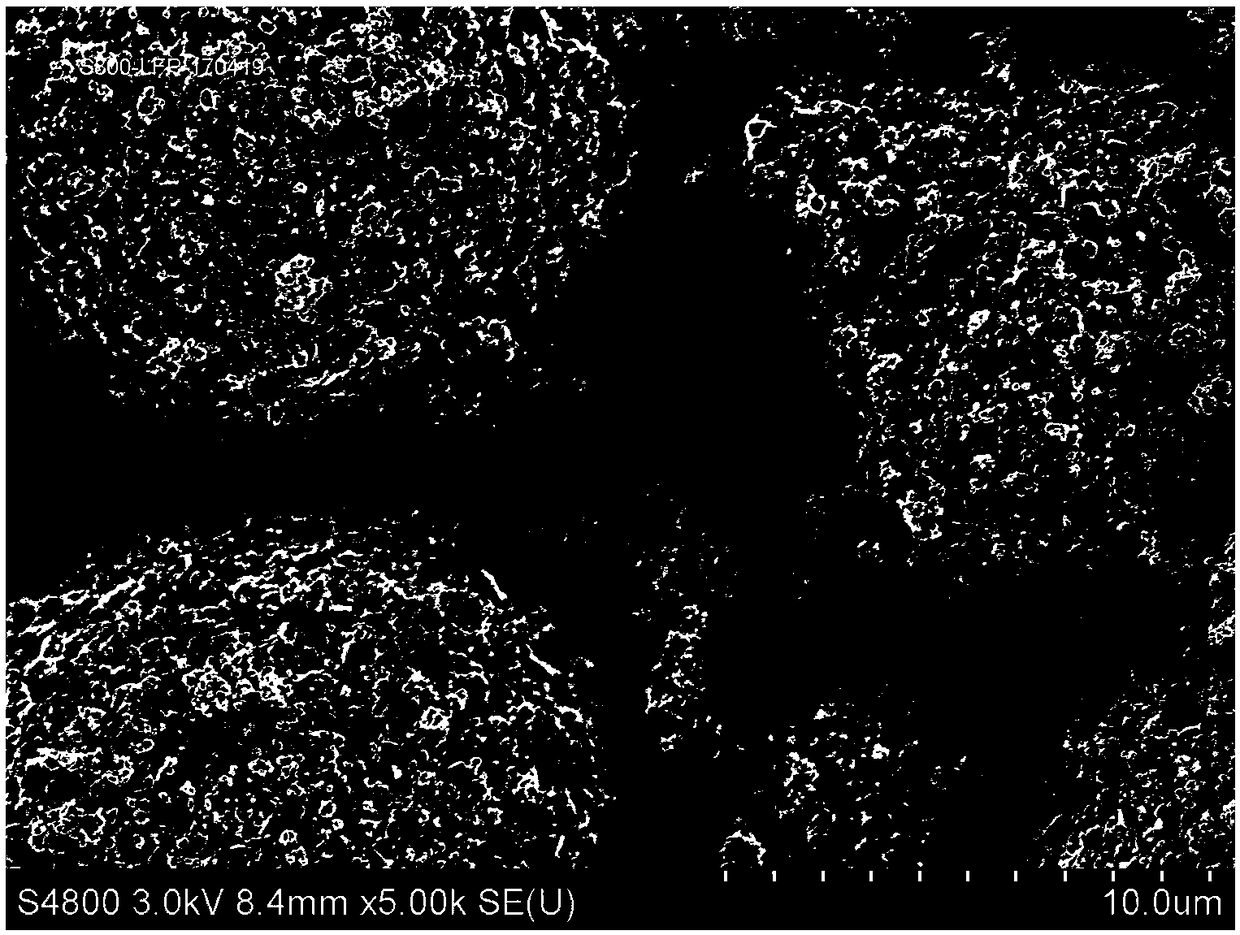

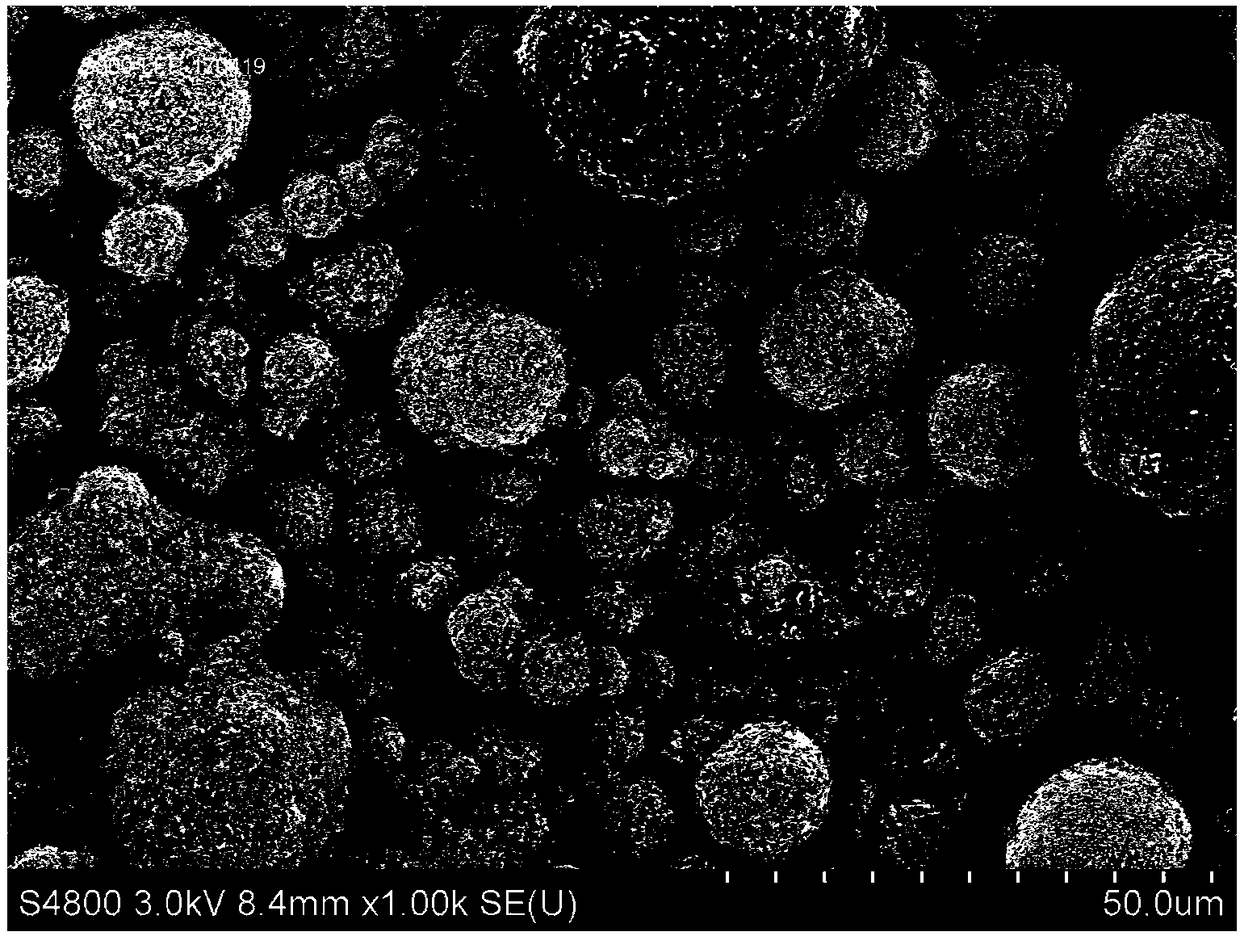

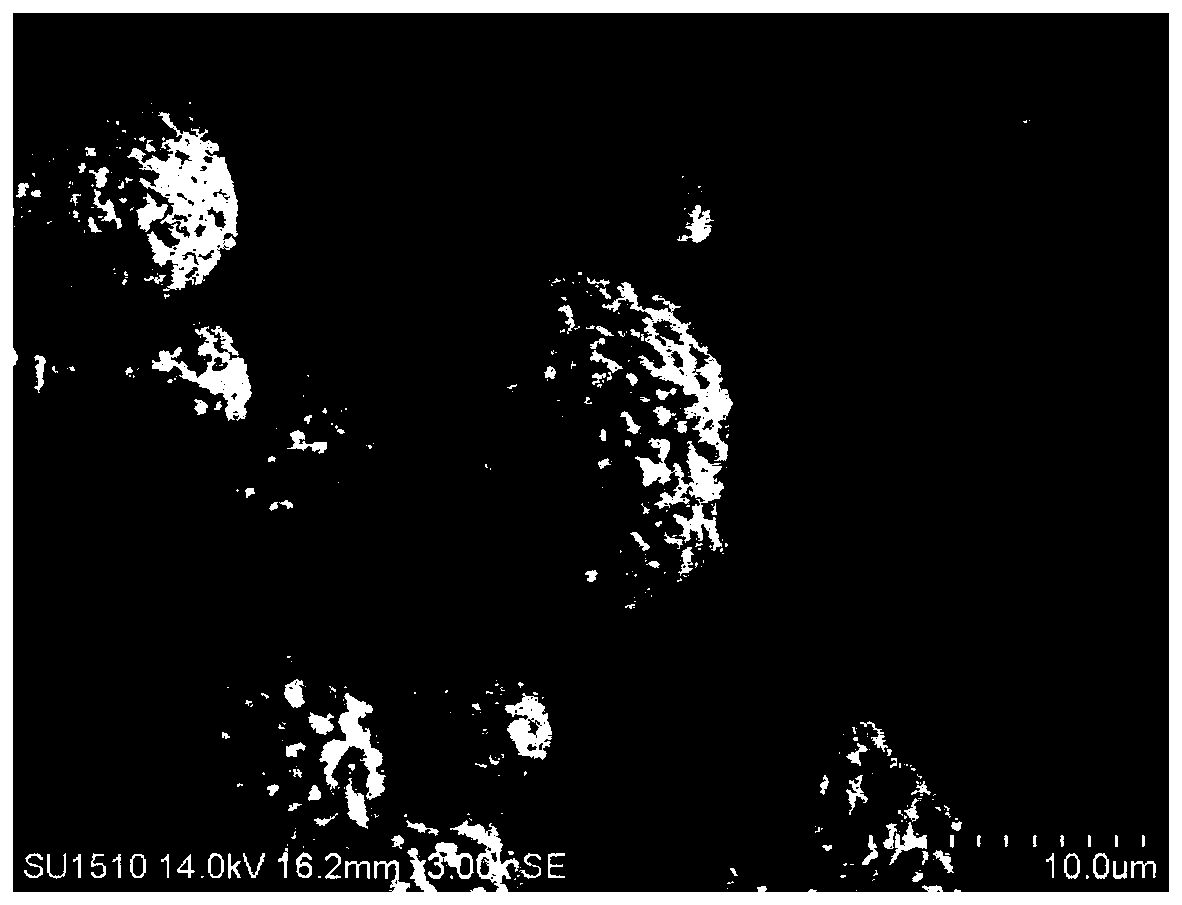

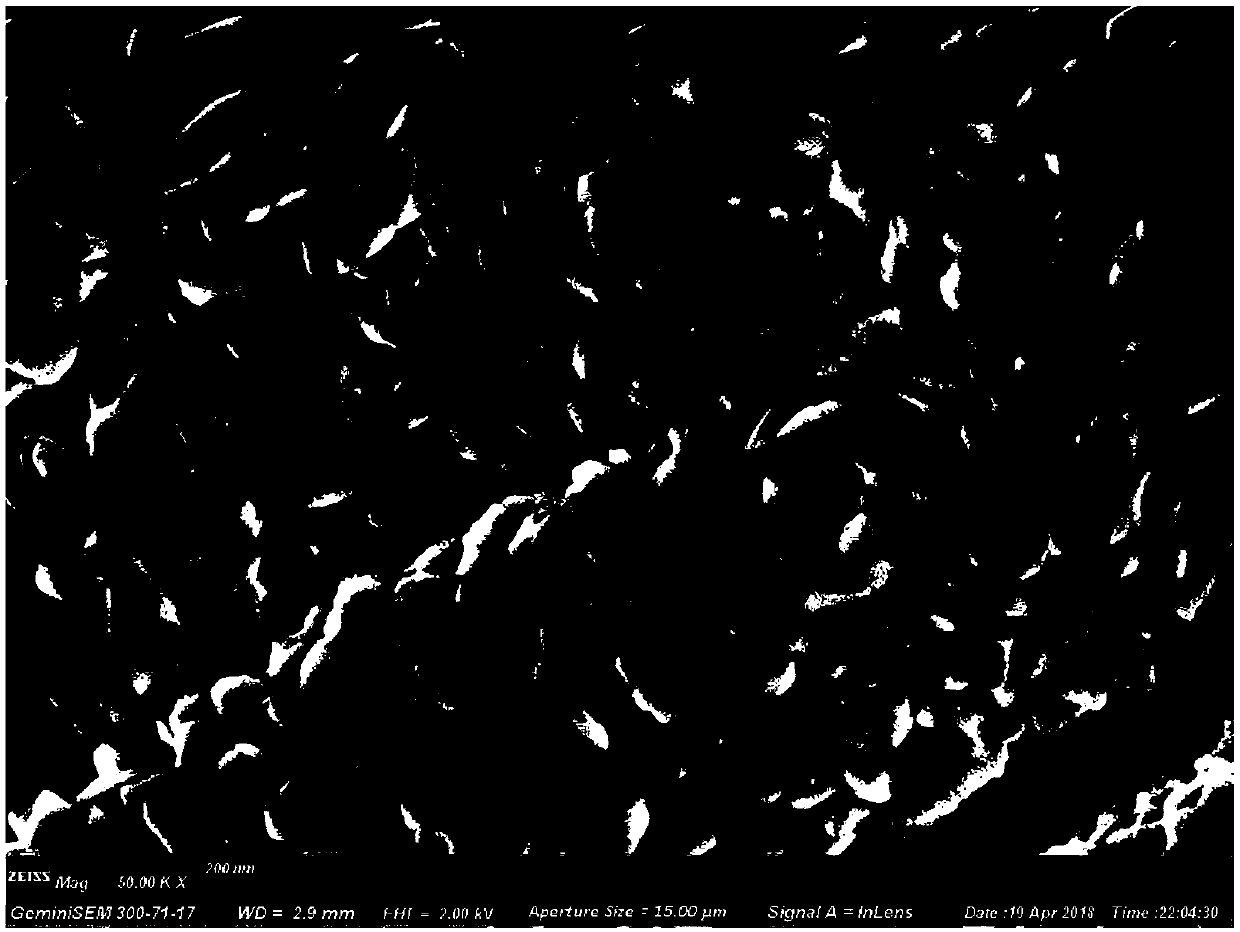

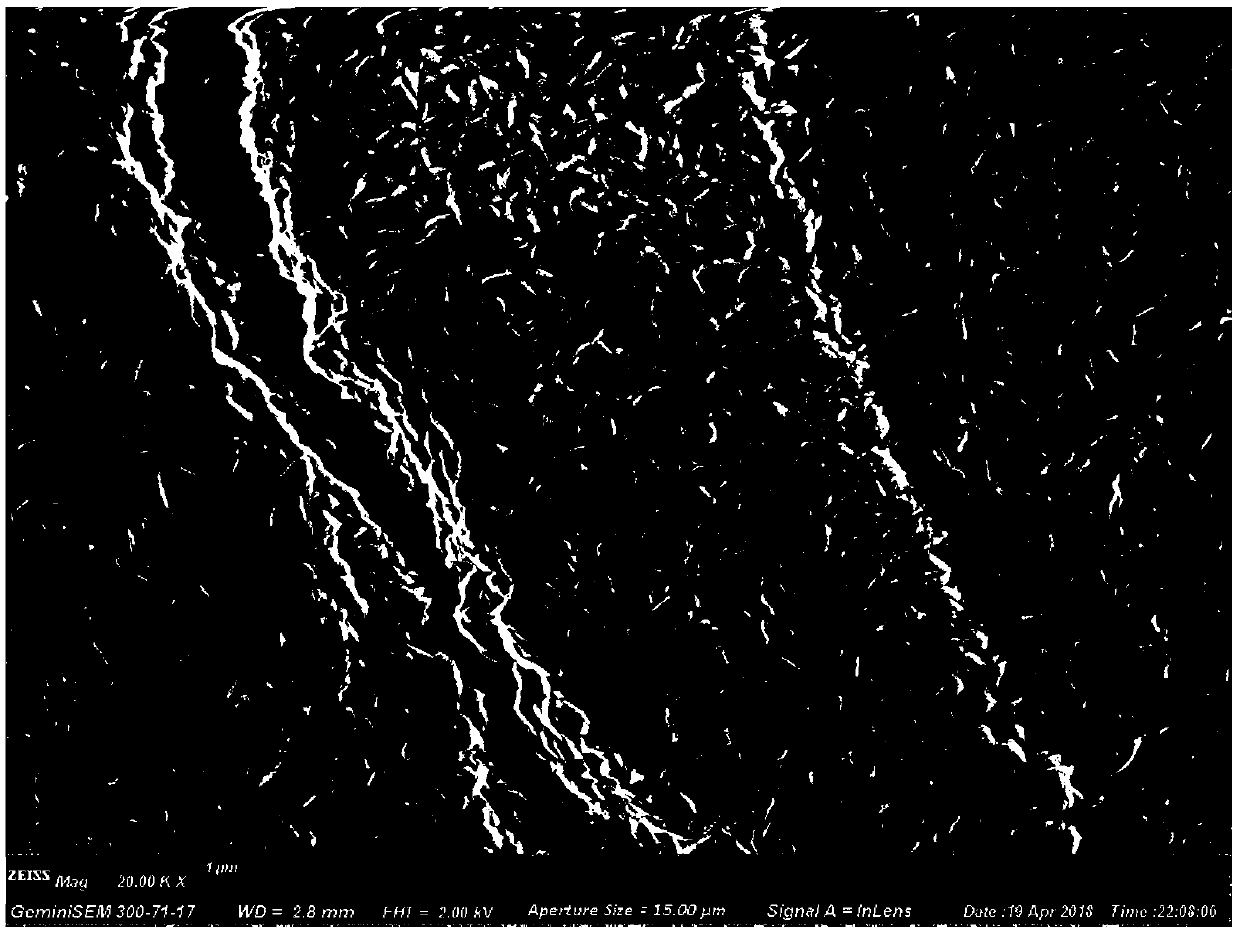

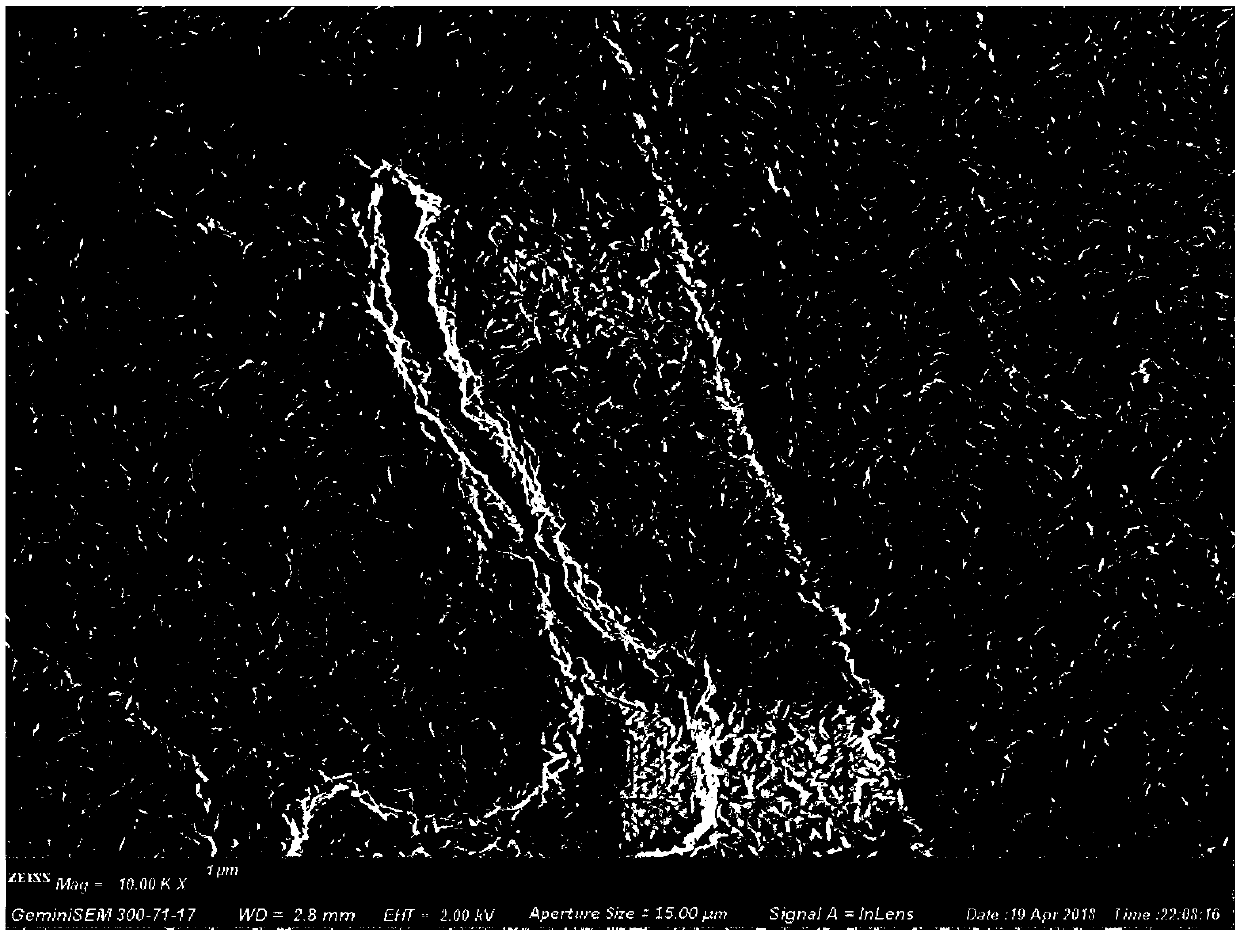

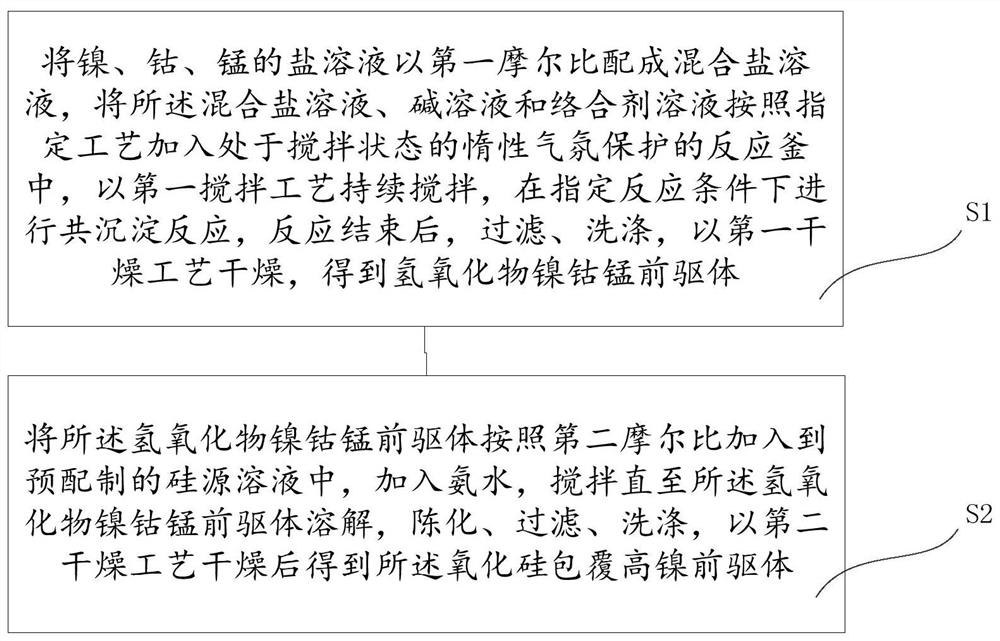

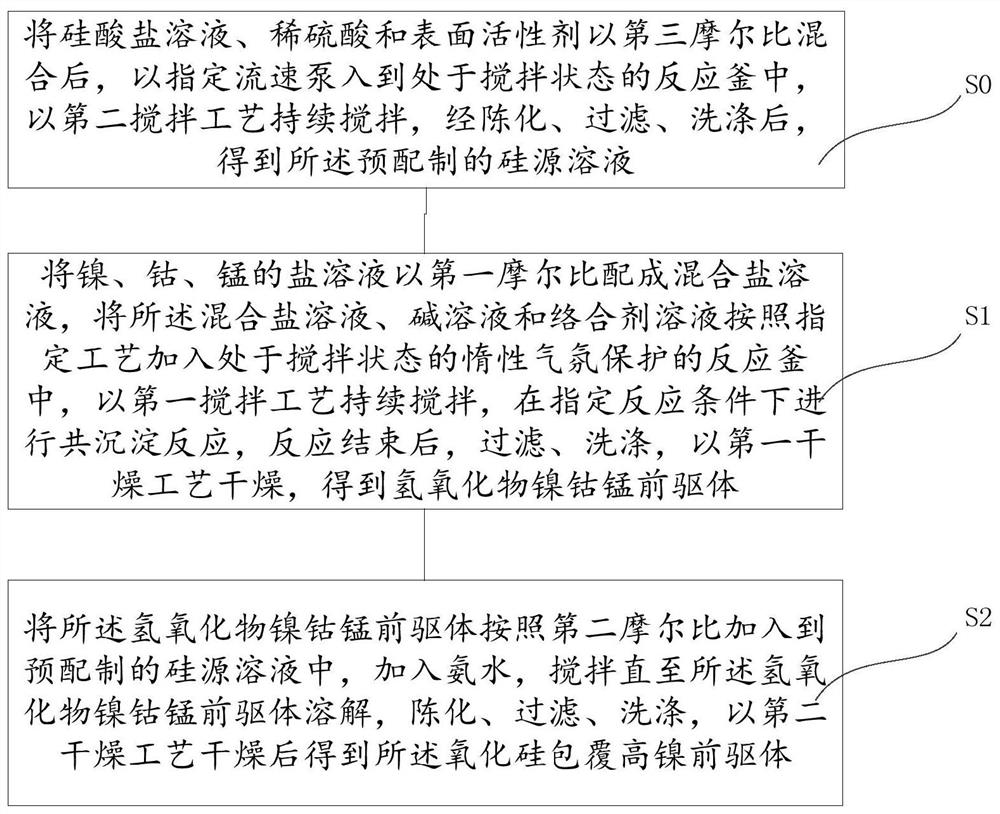

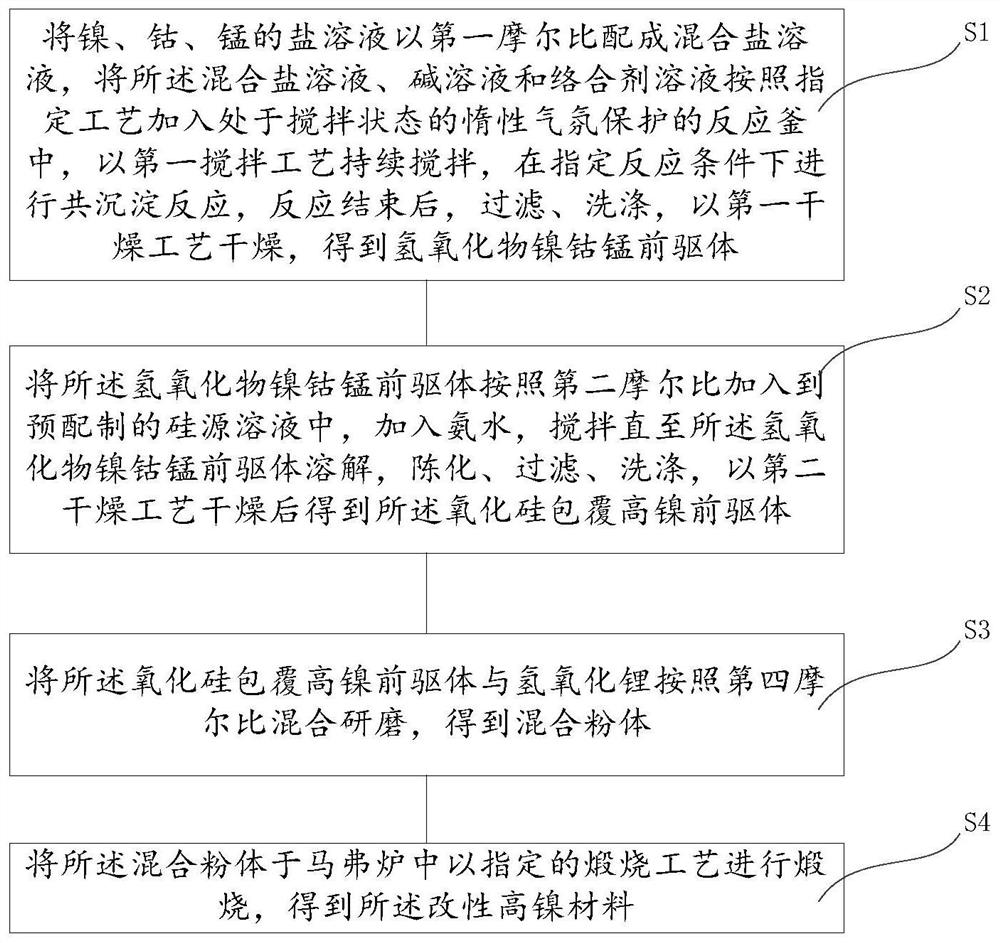

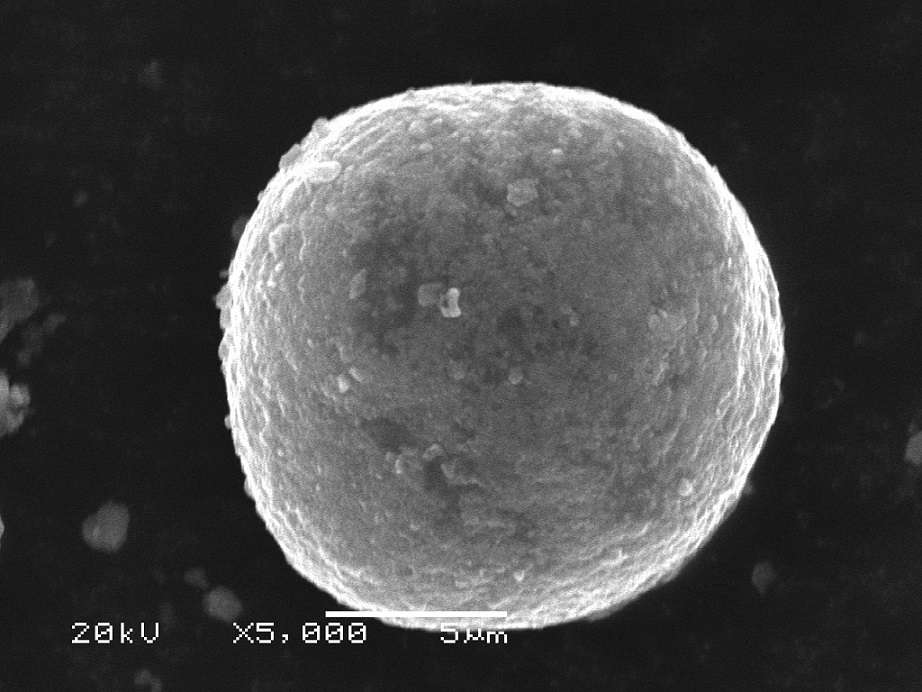

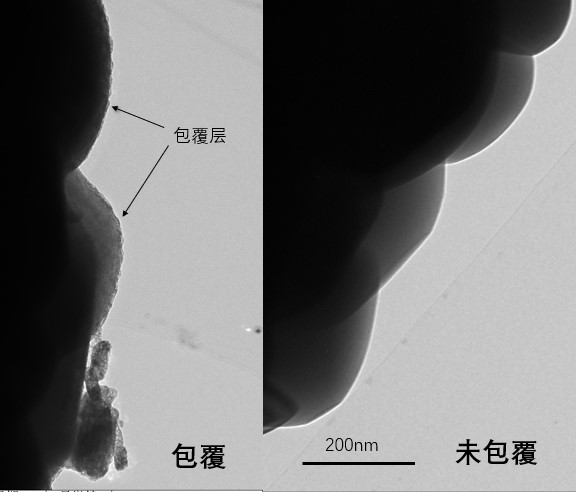

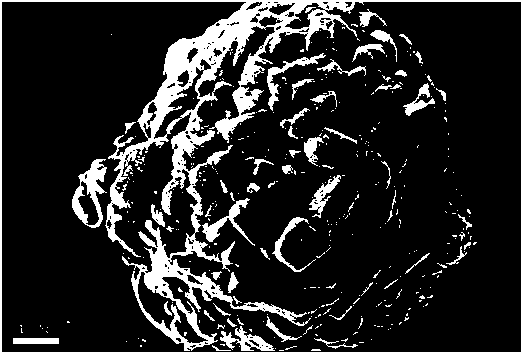

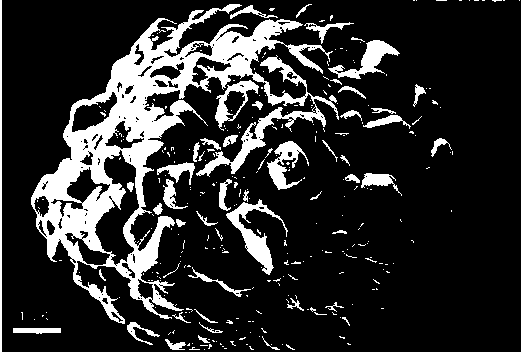

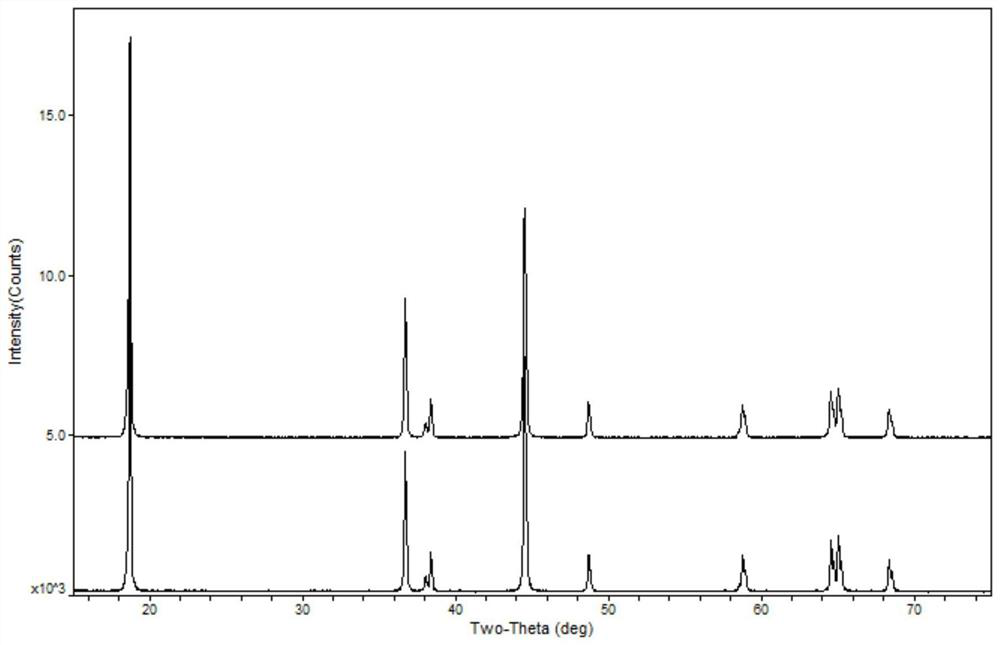

Silicon oxide-coated high-nickel precursor, modified high-nickel material and preparation method thereof

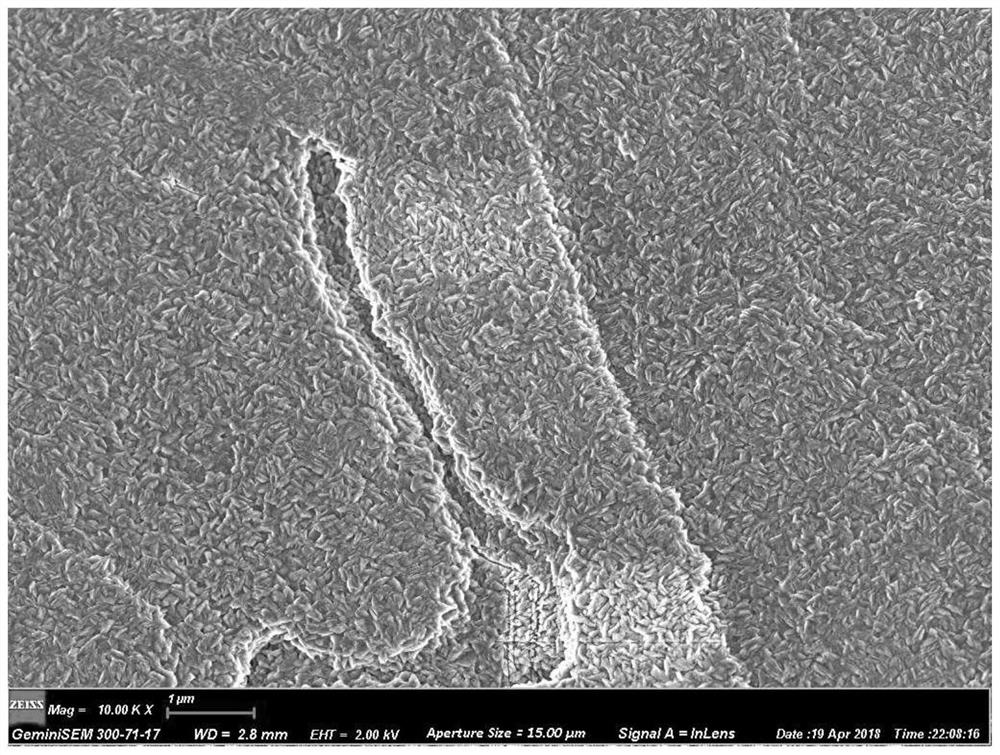

The invention discloses a silicon oxide-coated high-nickel precursor, a modified high-nickel material and a preparation method thereof, comprising the following steps: preparing a salt solution of nickel, cobalt and manganese into a mixed salt solution, mixing the mixed salt solution, The solution and the complexing agent solution are added to the reaction kettle protected by an inert atmosphere in a stirring state, and the stirring is continued, and the co-precipitation reaction is carried out under the specified reaction conditions. After the reaction is completed, filter, wash, and dry to obtain the nickel-cobalt-manganese hydroxide precursor body; Add the nickel hydroxide nickel cobalt manganese precursor to the pre-prepared silicon source solution, add ammonia water, stir until the nickel hydroxide nickel cobalt manganese precursor dissolves, age, filter, wash, and dry to obtain silicon oxide coating High nickel precursor. The present invention performs SiO on the high-nickel precursor by wet coating 2 Coating is conducive to the uniform dispersion of materials, so that SiO 2 It is coated on the surface of the precursor in the form of nanoparticles, thereby improving the cycle and storage performance of the modified high-nickel material.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Lithium zirconium phosphate fast ion conductor coated nickel cobalt lithium aluminate positive electrode material and preparation method

ActiveCN109192956BImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsElectrical conductorLithium aluminate

Lithium zirconium phosphate fast ion conductor coated nickel cobalt lithium aluminate positive electrode material and preparation method thereof, the mass of the lithium zirconium phosphate fast ion conductor is 0.1-10wt%, and the lithium zirconium phosphate fast ion conductor is formed into a layer with a thickness of 5-30nm The coating layer is coated on lithium nickel cobalt aluminate; the positive electrode material is a spherical particle with a particle diameter of 5-15 μm. The preparation method includes the following steps: (1) Prepare a solution containing phosphorus source and zirconium source, add zirconium source solution in organic solvent or water, then add phosphorus source solution, stir, then add nickel-cobalt lithium aluminate, heat and stir to react , slowly evaporated to dryness, and put the obtained powder into an oven for drying; (2) Put the powder obtained in step (1) in a tube furnace for low-temperature rapid sintering. The positive electrode material of the present invention has good cycle stability and rate discharge performance; the method of the present invention can effectively reduce the problems of surface residual lithium and low cycle stability of ternary materials during conventional coating, the process cost is low, the process is simple, and it is suitable for large industrial production.

Owner:CENT SOUTH UNIV

A kind of positive electrode lithium supplement material and preparation method and application thereof

ActiveCN113140722BReduce shufflingReduce residual lithiumPositive electrodesSecondary cells servicing/maintenanceLithiumBattery cell

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

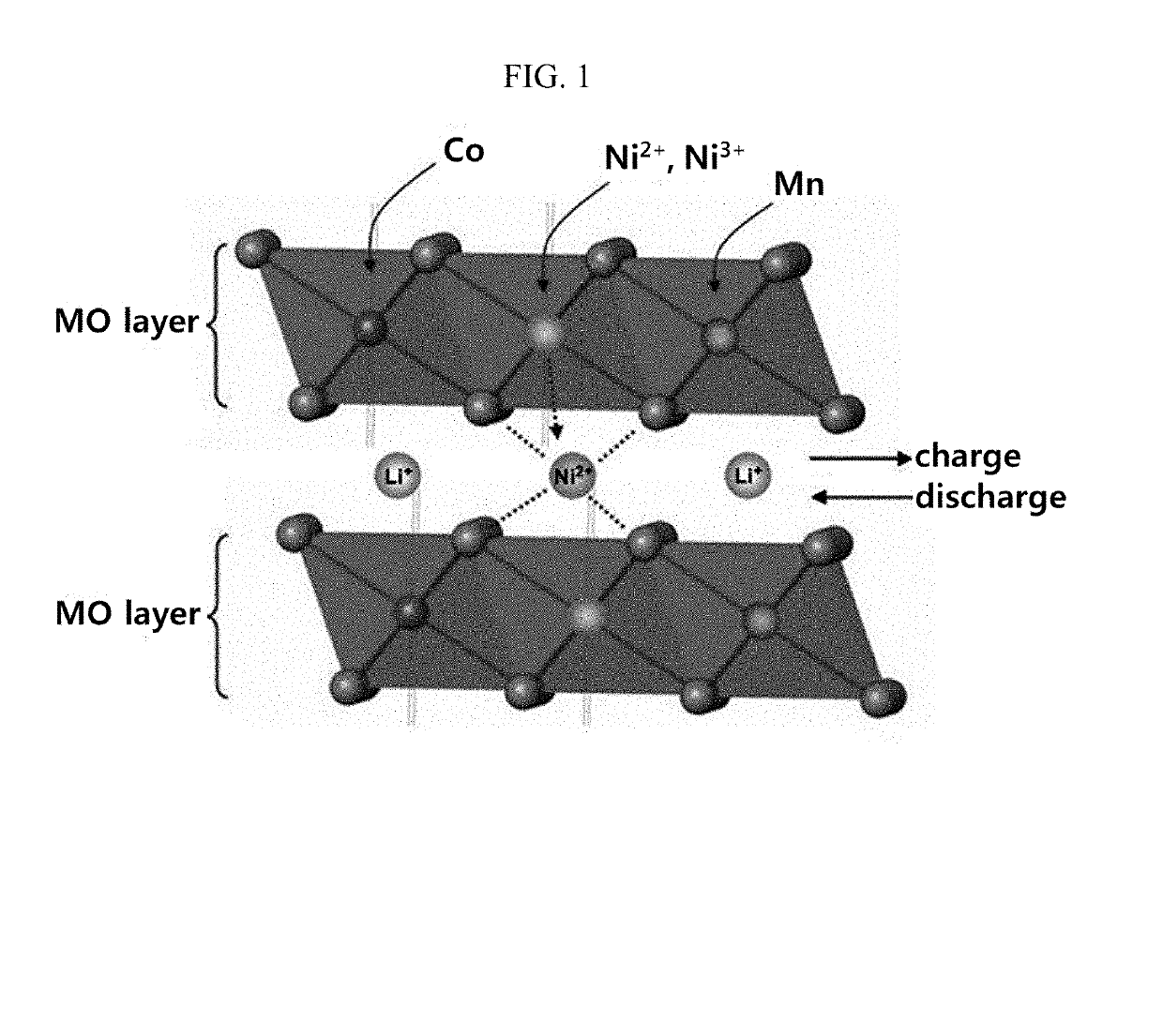

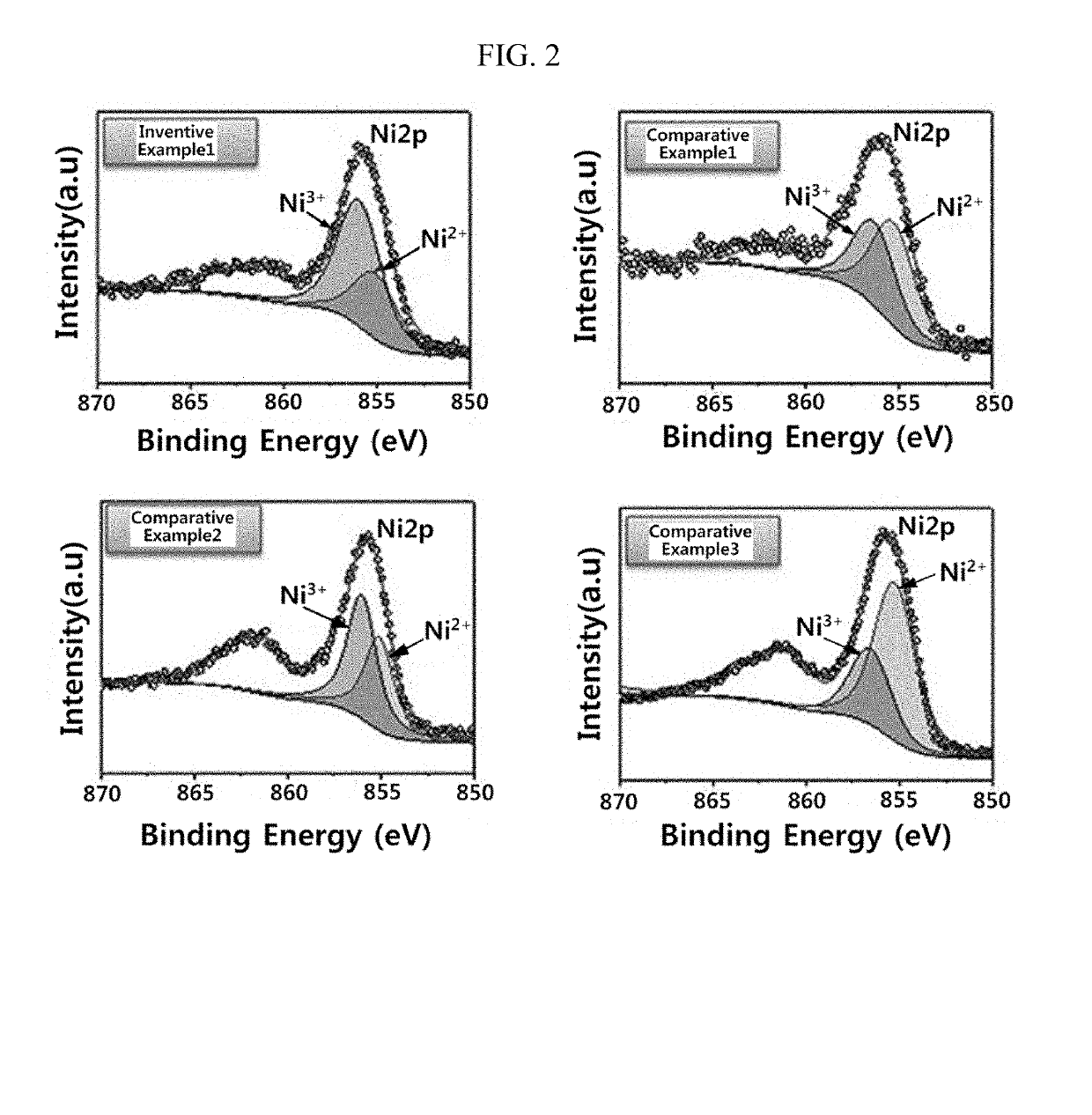

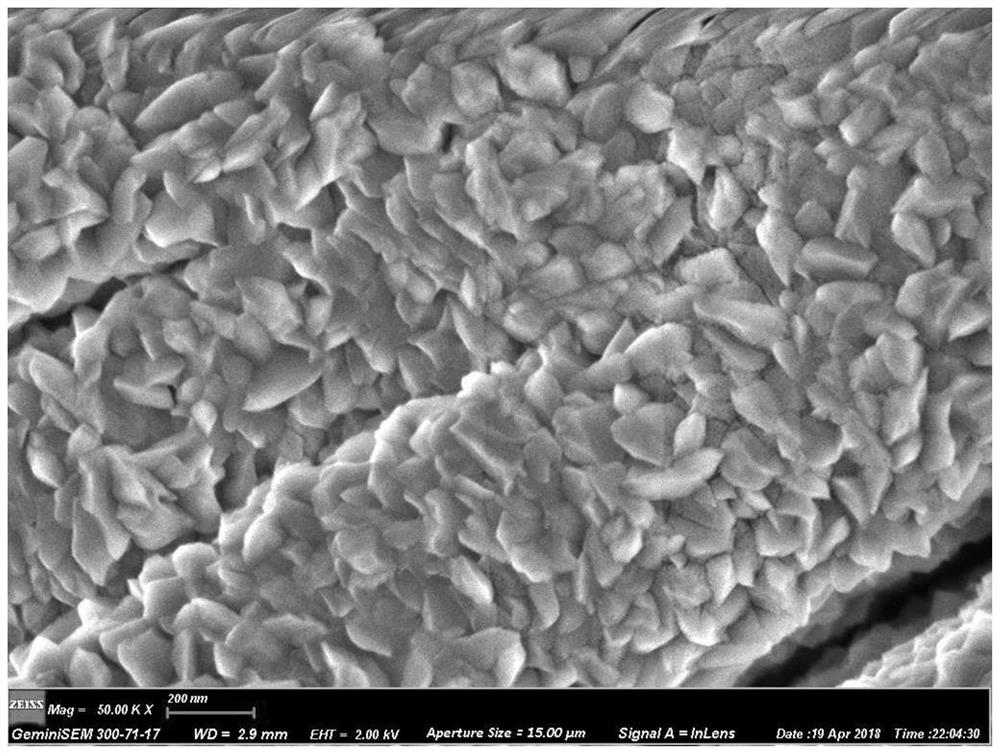

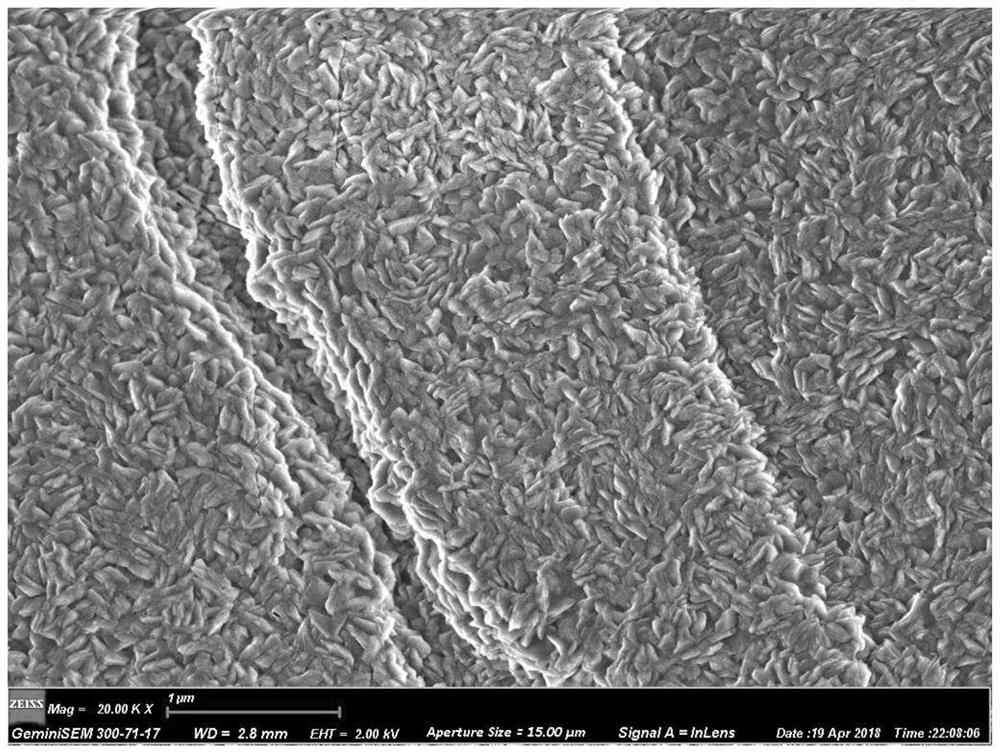

Lithium Metal Complex Oxide and Manufacturing Method of the Same

ActiveUS20190157672A1Increase capacityPrevent degradationCell electrodesNickel compoundsLithium metalMetal

Owner:ECOPRO BM CO LTD

Lithium hydroxide monohydrate, preparation method and application thereof, lithium ion battery cathode material and lithium ion battery

ActiveCN110817904BHigh purityLow magnetic element contentLithium oxides/hydroxidesPhysical chemistryLithium-ion battery

The present disclosure relates to a lithium hydroxide monohydrate, its preparation method and use, and lithium ion battery cathode material and lithium ion battery. The particle size of the lithium hydroxide monohydrate is 100-380 nm, and the monohydrate The content of Cu in lithium hydroxide is less than 1ppm, the content of Cr is less than 1ppm, the content of Ni is less than 2ppm, the content of Zn is less than 2ppm, and the content of Fe is less than 4ppm. The lithium hydroxide monohydrate has a low content of magnetic elements, and when used to prepare lithium-ion battery cathode materials, can improve the service life of the lithium-ion battery and reduce its self-discharge effect.

Owner:BYD CO LTD

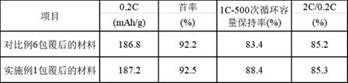

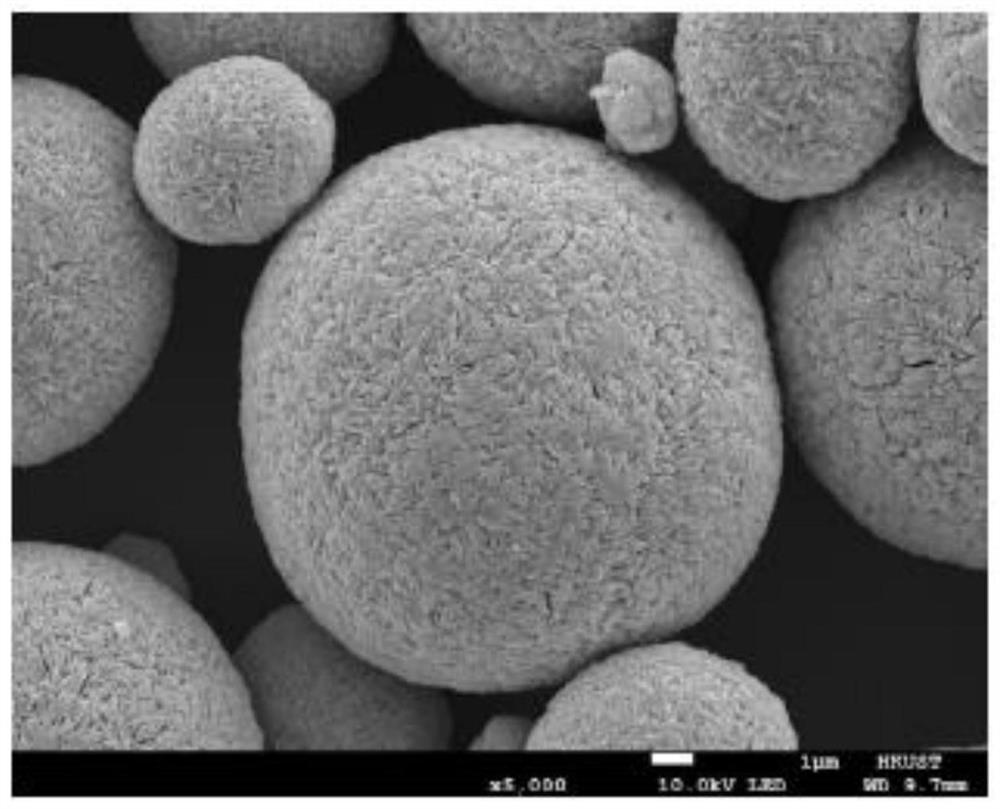

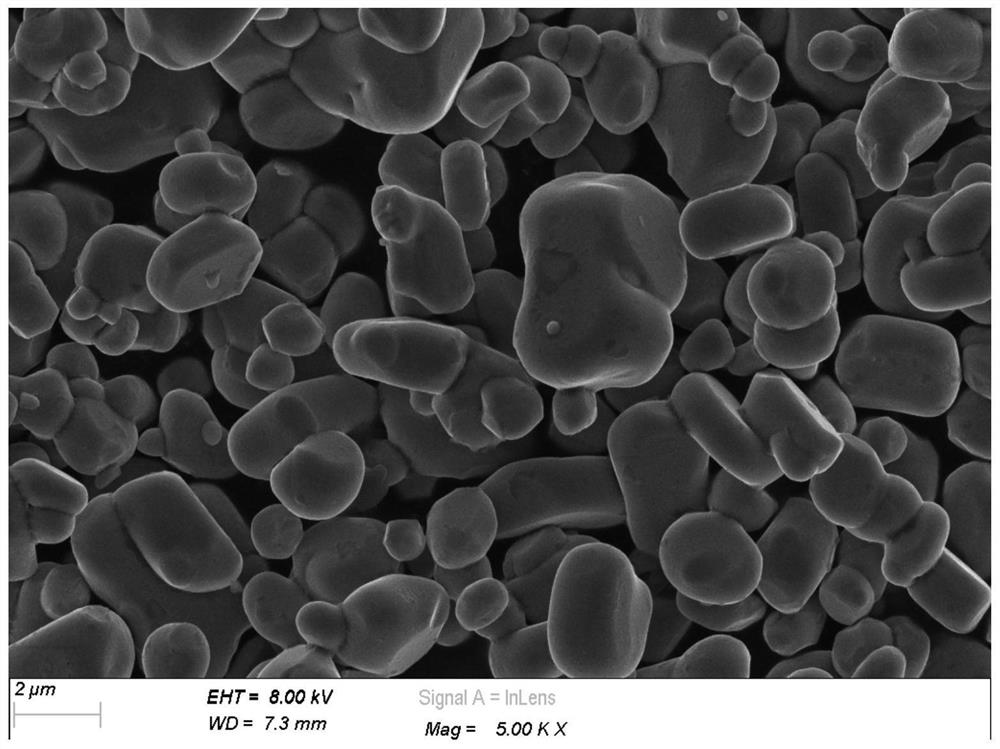

A kind of preparation method of high-capacity high-density high-nickel positive electrode material

ActiveCN107785550BImprove the shortcomings of insufficient compactionFacilitate de-intercalationMaterial nanotechnologyCell electrodesLithium hydroxideGrain growth

Owner:湖南桑瑞新材料有限公司

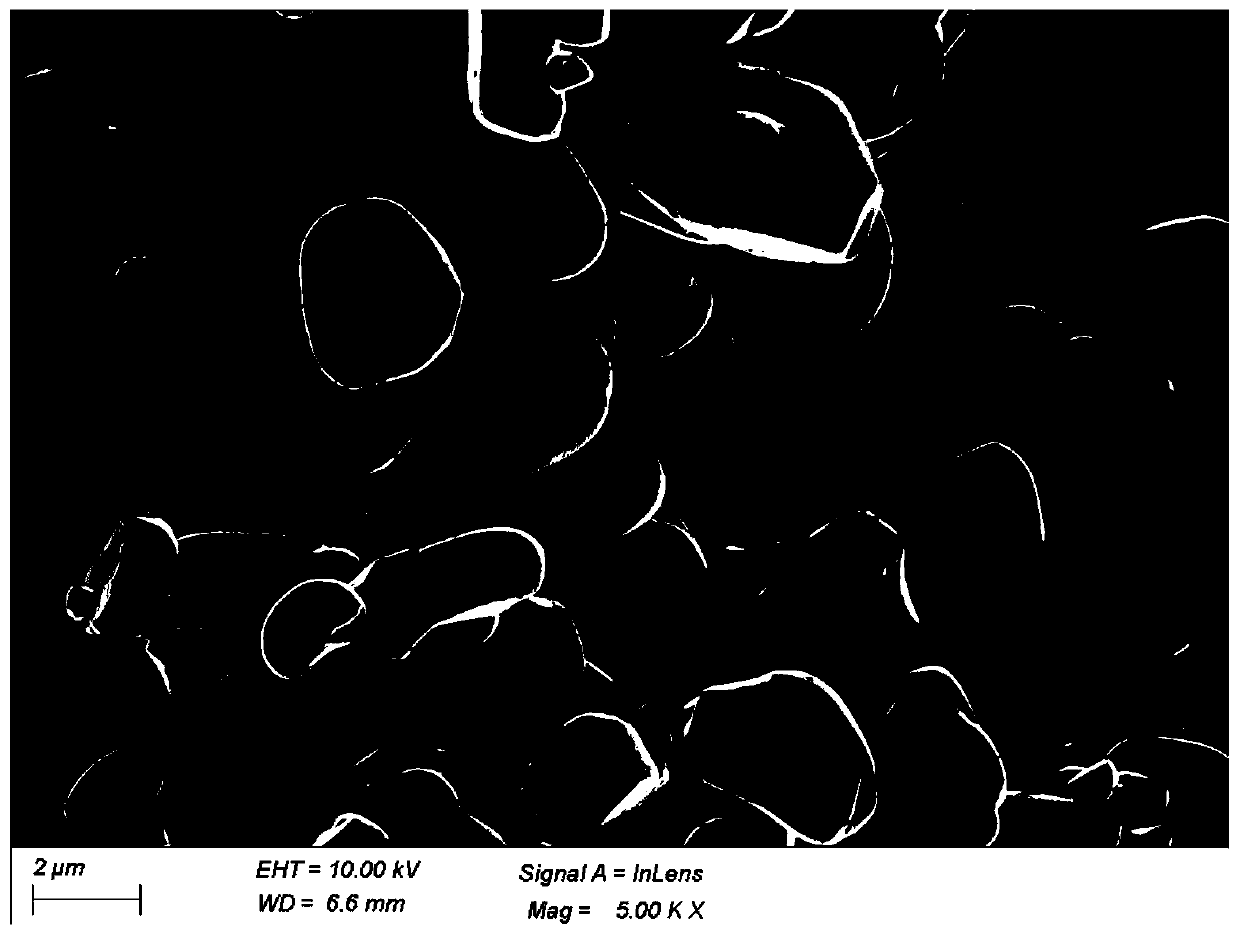

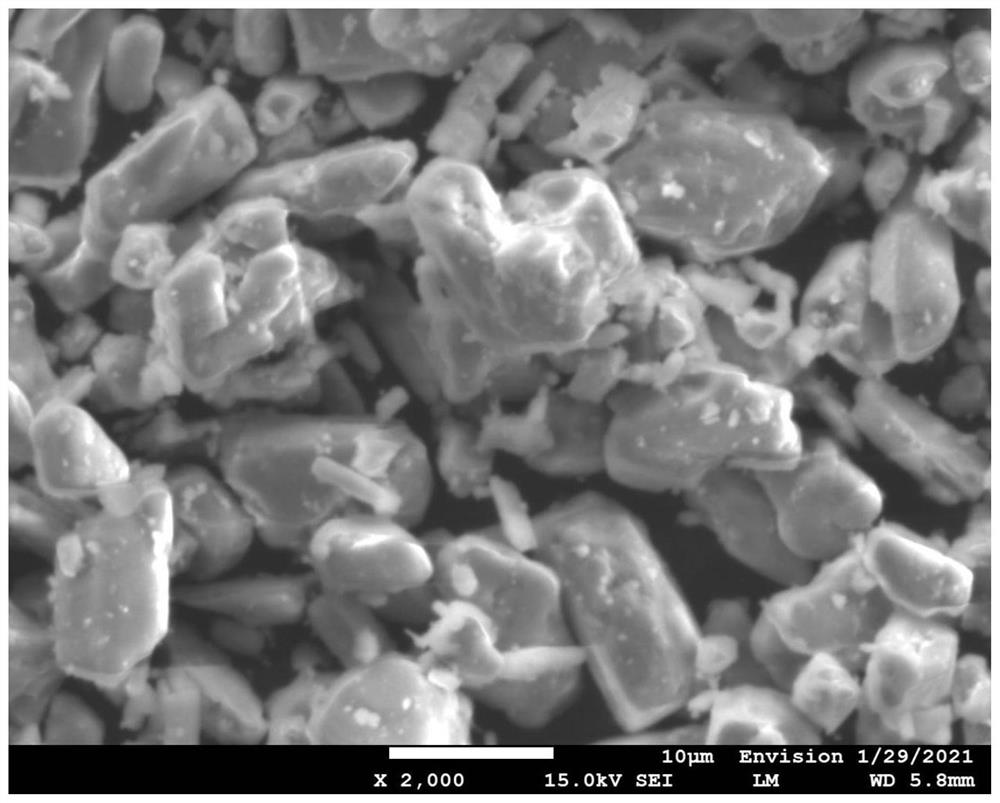

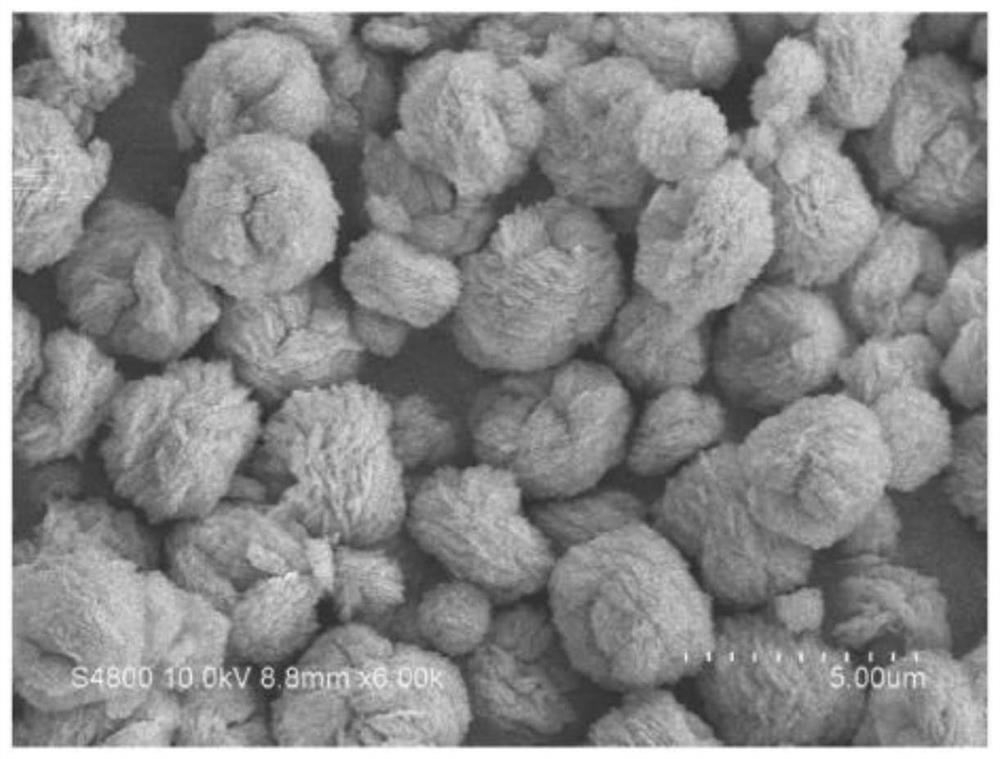

Doped nickel cobalt lithium manganese oxide precursor and preparation method thereof, doped nickel cobalt lithium manganese oxide positive electrode material

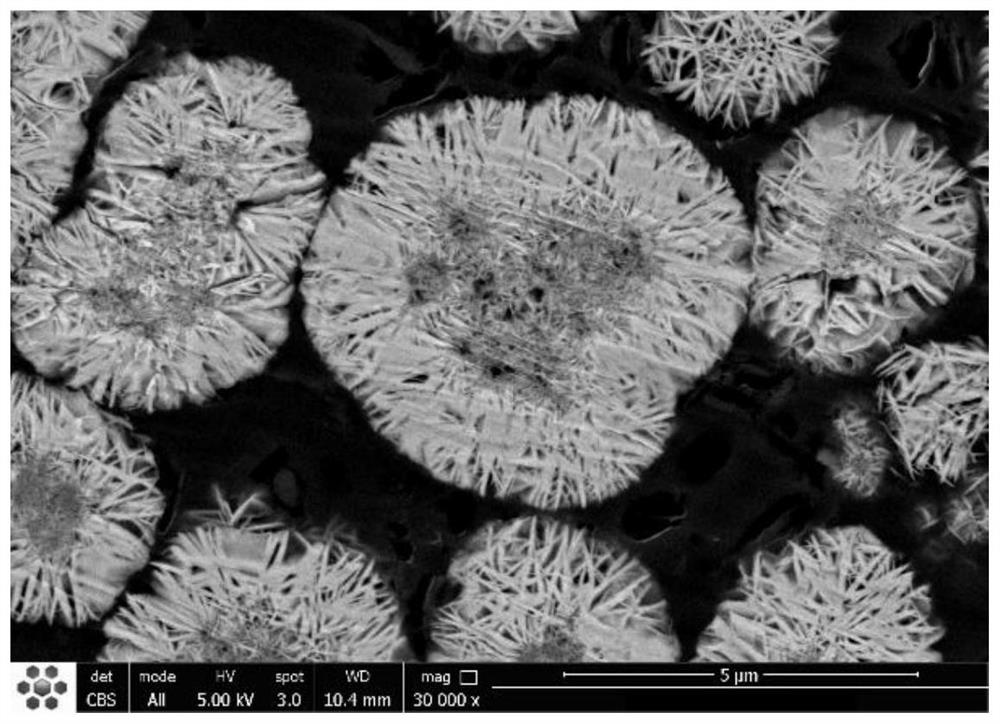

ActiveCN113036119BReduce residual lithiumImprove electrochemical performanceSecondary cellsPositive electrodesPhysical chemistryManganate

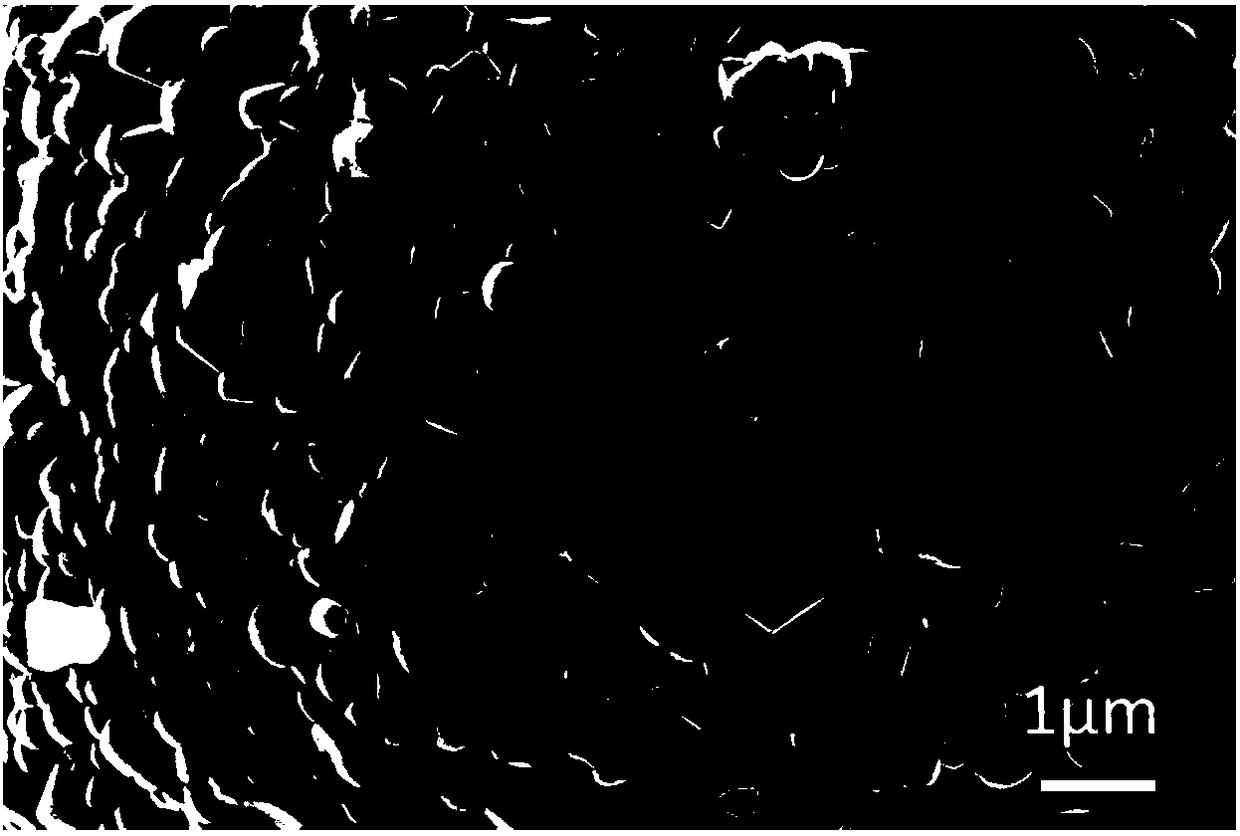

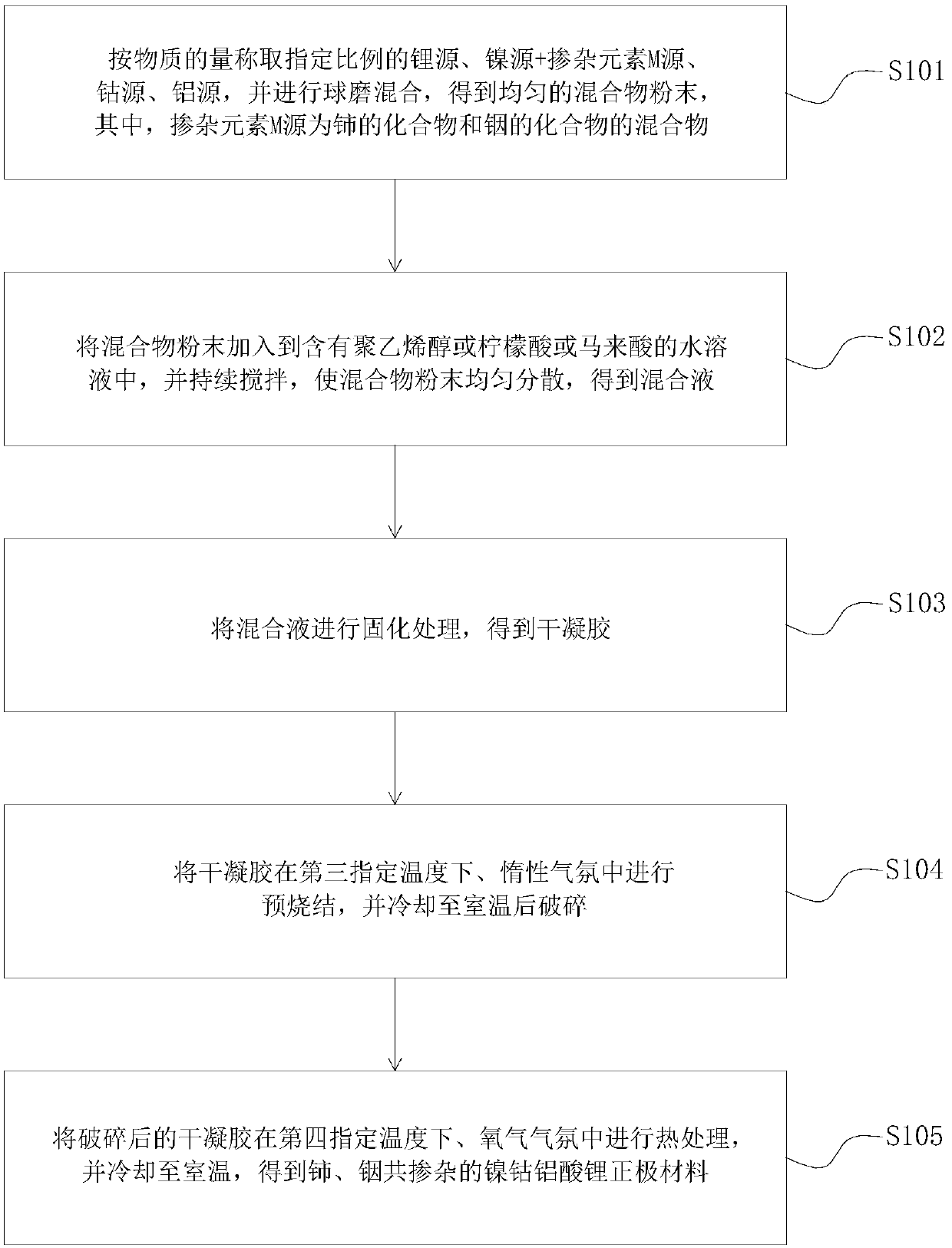

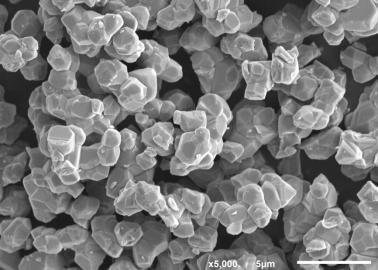

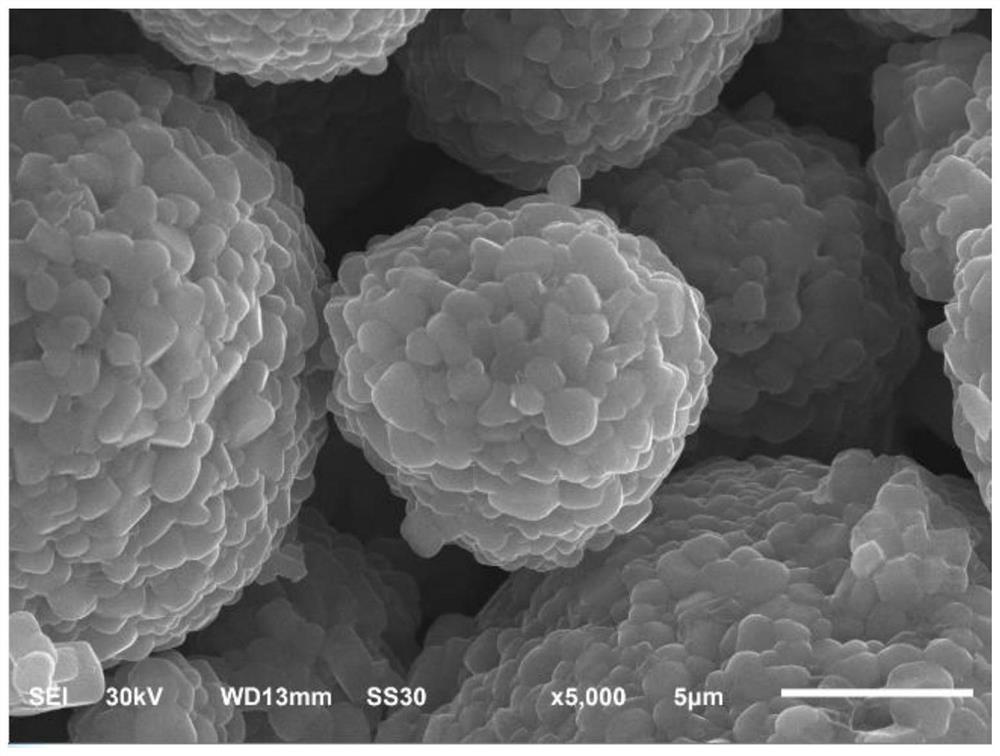

The invention discloses a doped nickel cobalt lithium manganate precursor, the molecular formula is Ni x co y mn z Al t (OH) 2+3t ·nWO 4 , where x+y+z=1, 0.4<x<1.0, 0<y≤0.5, 0<z≤0.5, 0<t<0.2, 0<n<0.2, Al and W are in the atomic scale in the precursor The uniform mixing on the surface, the primary particles of the precursor are regular lath-shaped and vertically loosely arranged, and the secondary particles are spherical in shape with a diameter distance not greater than 0.75. The preparation method of the doped nickel cobalt lithium manganate precursor is also disclosed. The doping elements in the precursor material of the present invention realize uniform mixing at the atomic level, which is beneficial to improving the electrochemical performance of the positive electrode material, and the secondary particles of the precursor material of the present invention do not crack during the production process, and the shape remains intact. The preparation method has a simple process flow, can stably prepare a good-quality precursor in batches, and has broad application prospects.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

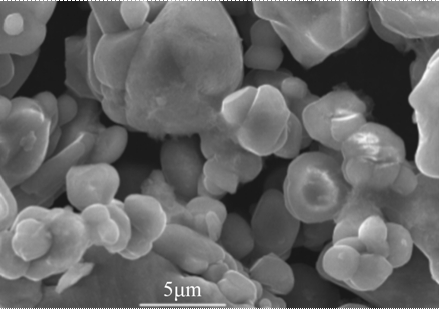

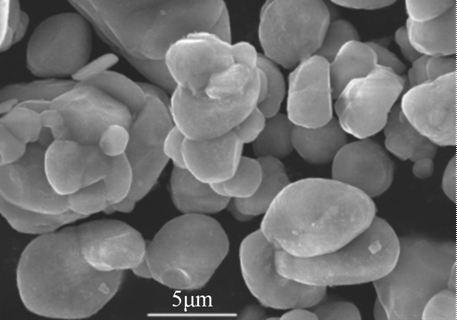

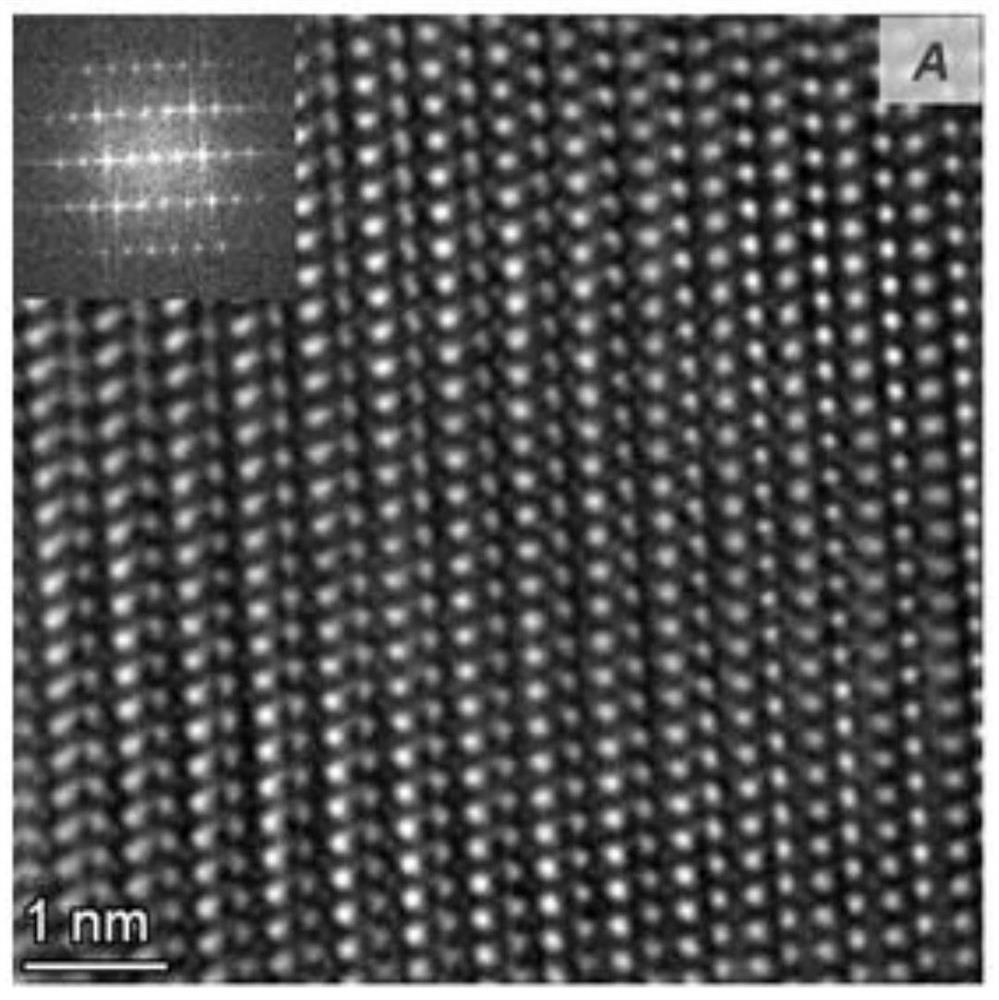

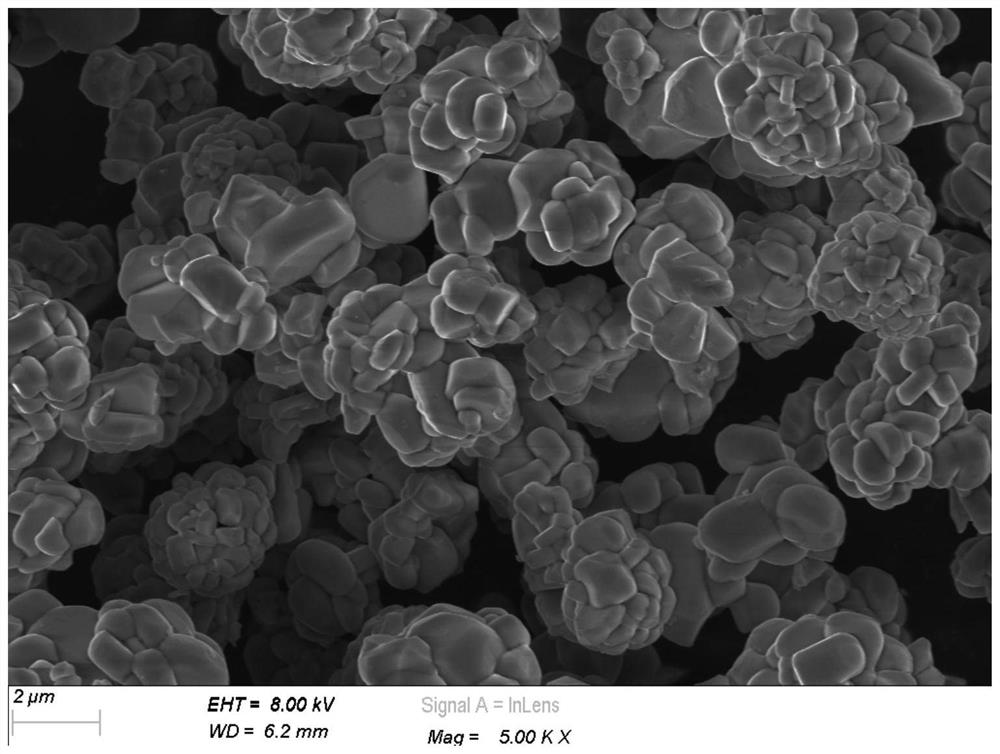

Positive electrode active material for rechargeable lithium battery, preparation method thereof, and rechargeable lithium battery including positive electrode containing positive electrode active material

ActiveCN111587500BImprove stabilityGood electrochemical propertiesElectrode thermal treatmentPositive electrodesLithium batteryComposite material

A positive active material for a rechargeable lithium battery includes: a first positive active material comprising secondary particles comprising at least two agglomerated primary particles, wherein at least a portion of the primary particles have radially arranged structure; and a second cathode active material having an individual structure. Both the first positive electrode active material and the second positive electrode active material may include a nickel-based positive electrode active material. Also provided are methods for preparing the positive electrode active material and a positive electrode rechargeable lithium battery including the positive electrode active material.

Owner:SAMSUNG SDI CO LTD

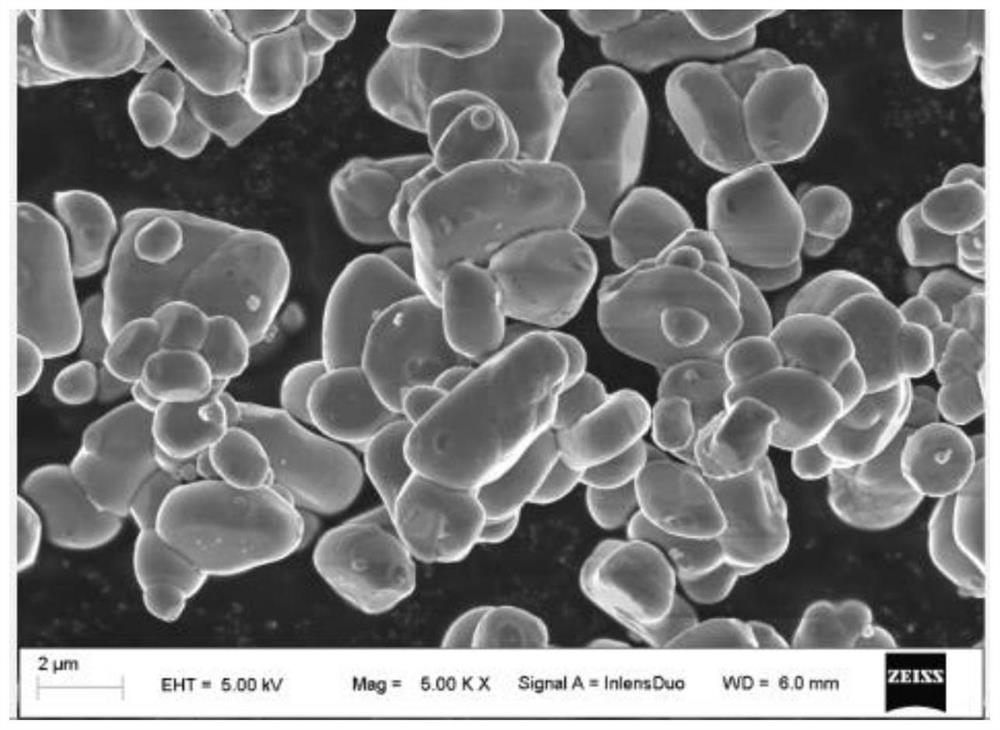

Nickel cobalt lithium manganese oxide positive electrode material and preparation method thereof

ActiveCN108172822BIncrease energy densityReduce residual lithiumCell electrodesLithium hydroxideElectrical battery

The invention relates to a lithium nickel cobalt manganate positive electrode material and a preparation method thereof. The preparation method comprises the following steps of preparing seed crystalby adopting a hydrothermal method; performing a coprecipitation reaction on the seed crystal to obtain an Ni<x>Co<y>Mn<1-x-y>(OH)<2>, enabling the precursor to be mixed with lithium hydroxide or lithium carbonate at a molar ratio of Li to (Ni+Co+Mn) of 1:1-1.2, and next, performing sintering treatment on the mixture to obtain an intermediate body; enabling the intermediate body to be mixed with lithium hydroxide, and next, spraying metal sol to obtain a pre-coating material; and performing secondary sintering on the pre-coating material to obtain the lithium nickel cobalt manganate positive electrode material. The lithium nickel cobalt manganate positive electrode material prepared by the preparation method has the monocrystal appearance; and the lithium ion battery adopting the positive electrode material is high in energy density which can reach as high as 300wh / kg, and the cycle life can reach 3,000 times.

Owner:ZOLTRIX MATERIAL GUANGZHOU

Surface-coated ternary cathode material and preparation method thereof

ActiveCN106941162BImprove cycle retentionImprove Interface StabilityMaterial nanotechnologyCell electrodesAlkalinityNanoparticle

The invention discloses a surface-coated ternary positive electrode material and a preparation method thereof, belonging to the technical field of lithium ion battery positive electrode materials. The present invention includes molecular formula is LiNi x co 1‑x‑y mn y o 2 particles, the LiNi x co 1‑x‑y mn y o 2 The particle surface is covered with Li 2 MTiO 4 Nanoparticles, wherein M is at least one metal element in Ni, Co, and Mn. The present invention LiNi x co 1‑x‑y mn y o 2 The basic crystal phase structure of the battery is not destroyed, but a new phase of nanoparticles is coated on the surface to form surface protection, increase the interface stability between the surface of the positive electrode material and the electrolyte, and further improve the cycle retention rate of the material. Enhanced electrochemical performance. The surface alkalinity of the cathode material of the invention is reduced, the water absorption is suppressed, and the processing performance is improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

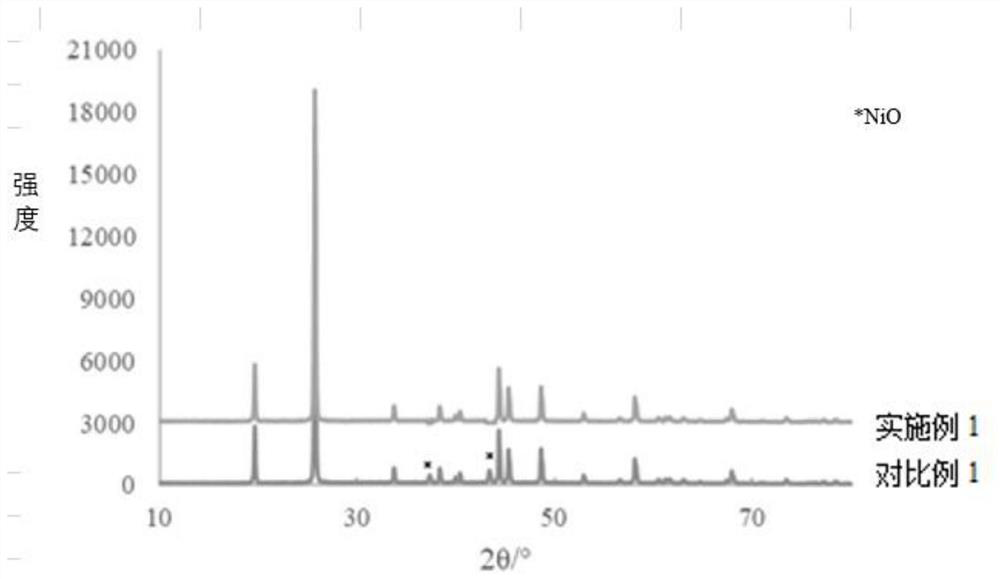

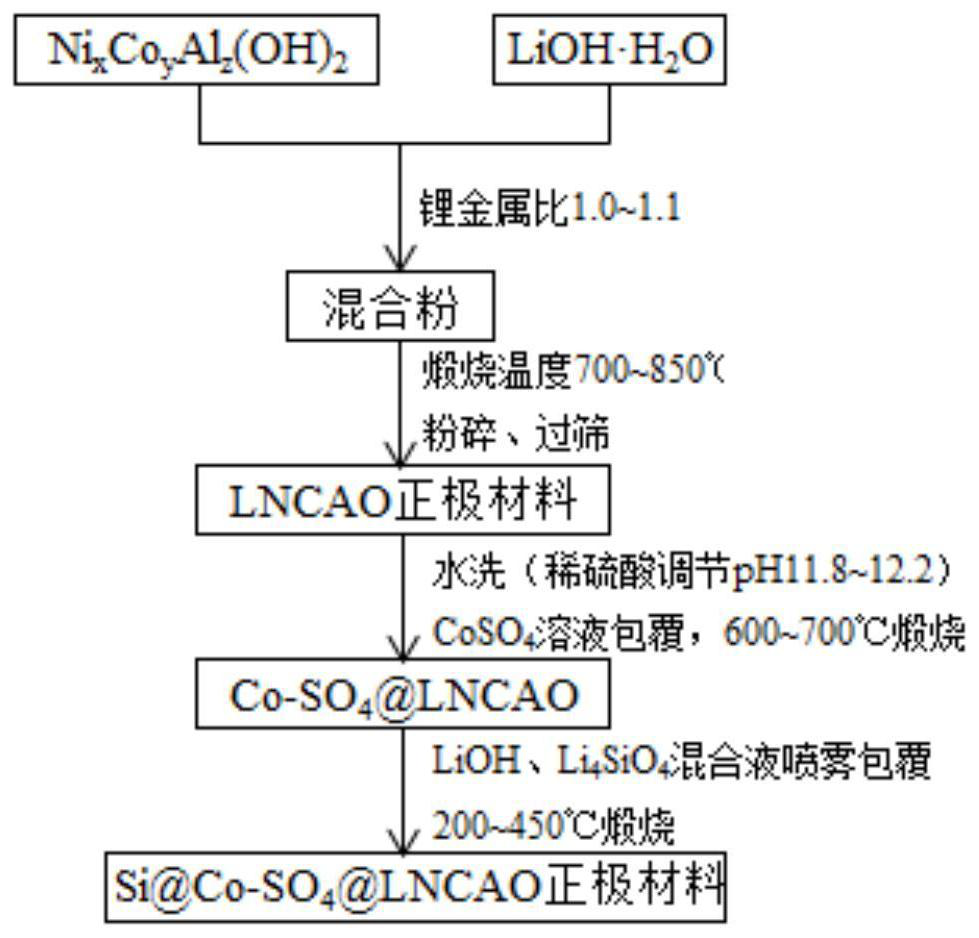

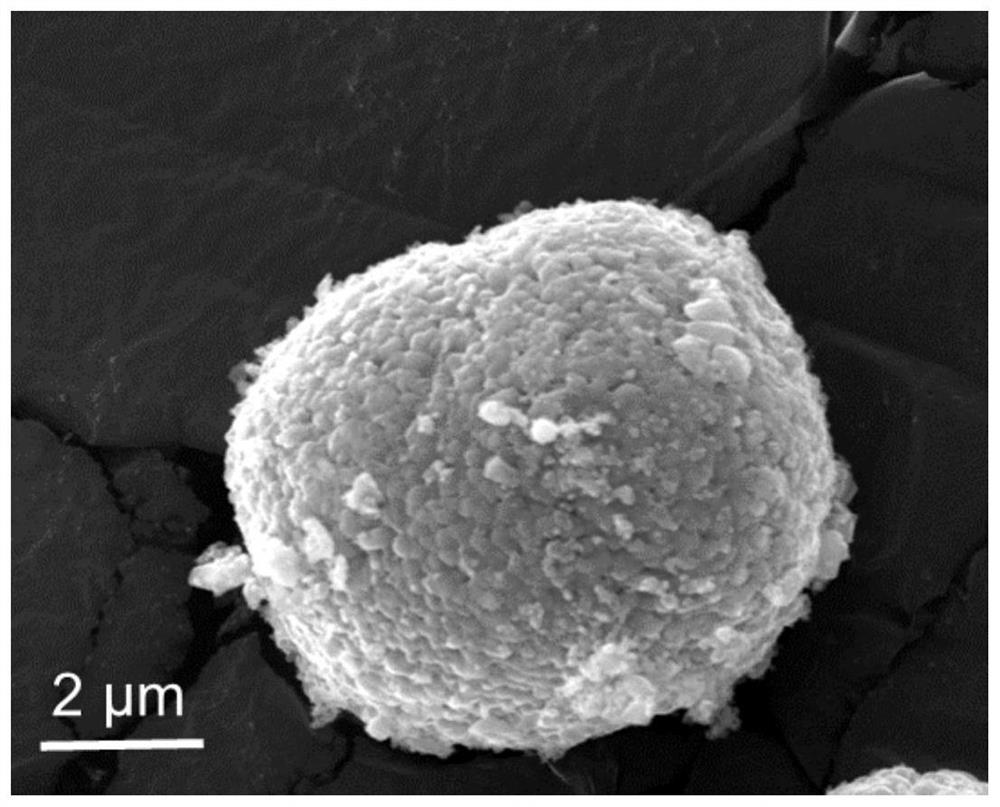

Preparation method of semi-doped and semi-coated NCA positive electrode material

PendingCN114039048AReduce residual lithiumLarge capacitySecondary cellsPositive electrodesAqueous electrolyteElectrical battery

The invention discloses a preparation method of a semi-doped and semi-coated NCA positive electrode material, and belongs to the technical field of positive electrode materials of non-aqueous electrolyte secondary batteries, the high-nickel NCA positive electrode material of LiOH is used, the process is redesigned, residual lithium of the positive electrode material can be obviously reduced, the capacity is increased, expansion of the battery is reduced, and the safety of the battery is improved; and the structural stability of the material is effectively improved through a semi-doping semi-coating and Si coating method, the electrolyte erosion resistance of the material is improved, and the capacity and circulation of the battery are further increased.

Owner:JILIN JIEN NICKEL IND

Calcium phosphate coated high-nickel ternary positive electrode material as well as preparation method and application thereof

ActiveCN114566647AReduce residual lithiumLess side effectsSecondary cellsPositive electrodesElectrolytic agentCalcium biphosphate

The invention provides a calcium phosphate coated high-nickel ternary positive electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing a calcium source solution and a phosphorus source solution; adding the calcium source solution into an organic solvent or water, uniformly stirring, then adding a high-nickel ternary positive electrode material and the phosphorus source solution, and heating and drying to obtain powder; and calcining the powder to obtain the calcium phosphate coated high-nickel ternary positive electrode material. The high-nickel ternary positive electrode material is firstly coated with calcium phosphate and then sintered, so that residual lithium on the surface of the high-nickel ternary positive electrode material can be effectively reduced, side reaction between the residual lithium and electrolyte is reduced, and the storage performance of the high-nickel ternary positive electrode material is improved.

Owner:WUHAN UNIV OF TECH

A kind of high-voltage nickel-cobalt lithium manganese oxide positive electrode material and preparation method thereof

ActiveCN109786697BImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganate

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

Modified ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN114314693AReduce residual lithiumLarge specific surface areaCell electrodesSecondary cellsPhysical chemistryManganese

The invention discloses a modified ternary positive electrode material and a preparation method thereof, and the preparation method comprises the following steps: uniformly mixing nickel-cobalt-manganese hydroxide and boric acid, and pre-sintering to obtain a pre-sintered material; uniformly mixing the pre-sintered material with a lithium source and a cationic additive, and performing primary sintering to obtain a ternary sintered material; and uniformly mixing the ternary sintered material with an anionic coating agent, and carrying out secondary sintering to prepare the modified ternary positive electrode material. The modified ternary positive electrode material has high structural stability and capacity and excellent high-temperature cycle performance. The invention also discloses a lithium ion battery containing the modified ternary positive electrode material, and the lithium ion battery has excellent electrical properties.

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

A kind of preparation method of single crystal ternary cathode material

ActiveCN109279659BImprove consistencyImprove stabilityCell electrodesSecondary cellsLithium oxideManganese

The invention discloses a preparation method of a single crystal ternary positive electrode material in the technical field of lithium ion batteries, which comprises mixing and ball milling lithium oxide and three oxides of nickel, cobalt and manganese in proportion; The first sintering is carried out at ℃; the product after the first sintering is then sintered at 650-780°C for the second time; finally, it is naturally cooled to room temperature to obtain a single crystal ternary cathode material. The present invention directly uses oxides as raw materials, avoiding the phenomenon of gas generation when hydroxides or carbonates are used as raw materials, thereby greatly improving the consistency of the atmosphere, the stability of heat and the cracking of structures; the present invention also By directly mixing lithium oxide with nickel, cobalt, and manganese oxides, it can be mixed evenly. The particle size of the sintered raw material is small, and the elements are evenly mixed, which provides the conditions for forming single crystal at a lower temperature.

Owner:CNGR ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com