Surface coating type ternary positive electrode material and preparation method thereof

A positive electrode material and surface coating technology, applied in the field of surface coated ternary positive electrode material and its preparation, can solve the problems of low specific capacity and cycle performance, failure to meet commercial requirements, unfavorable electron conduction, etc., to achieve enhanced electric capacity Effects of chemical properties, increased interface stability, and improved cycle retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure 1 mol of LiNi 0.8 co 0.1 mn 0.1 o 2 As the material to be coated, due to the existence of residual LiOH on the surface, the material is strongly alkaline, with a pH of about 12. At the same time, LiNi 0.8 co 0.1 mn 0.1 o 2 The residual lithium on the surface acts as Li 2 NiTiO 4 Lithium source, take 0.05 mol nano-titanium oxide as the titanium source, take 0.05 mol nickel hydroxide as the nickel source, mix the above materials uniformly by ball milling, and perform calcination at 400-800°C under air atmosphere for 10- 20 h. Obtaining surface-coated LiNi 0.8 co 0.1 mn 0.1 o 2 , namely Li 2 NiTiO 4 coated LiNi 0.8 co 0.1 mn 0.1 o 2 .

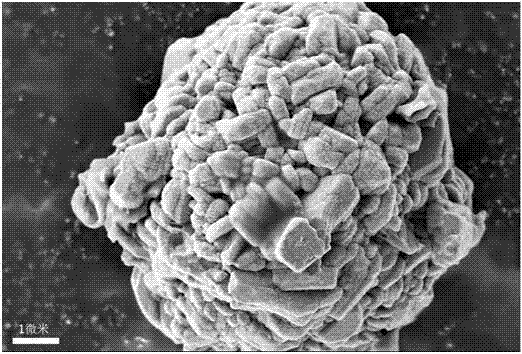

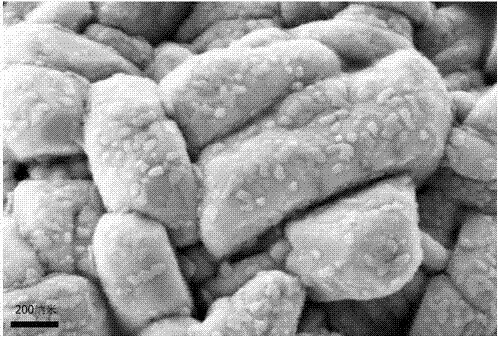

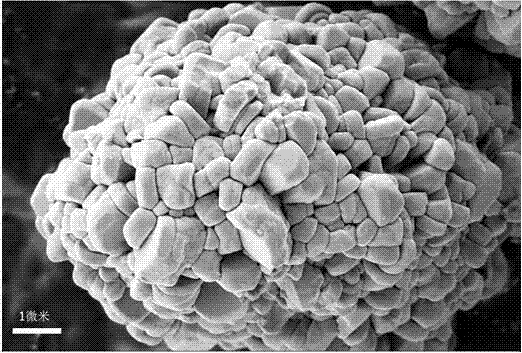

[0030] according tofigure 1 , figure 2 The test results show that the surface-coated LiNi 0.8 co 0.1 mn 0.1 o 2 Fine nanoparticles are evenly distributed on the surface of the particles, and the appearance of these nanoparticles indicates that the Li 2 NiTiO 4 In LiNi 0.8 co 0.1 mn 0.1 o 2 The surface ...

Embodiment 2

[0039] Measure 1 mol of LiNi 0.8 co 0.1 mn 0.1 o 2 As the material to be coated, due to the existence of residual LiOH on the surface, the material is strongly alkaline, with a pH of about 12. At the same time, LiNi 0.8 co 0.1 mn 0.1 o 2 The residual lithium on the surface acts as Li 2 CoO 4 Lithium source, measure 0.05 mol of titanium dioxide as the titanium source, measure 0.05 mol of manganese nitrate as the manganese source, mix the above materials uniformly by ball milling, and perform calcination at 400-800°C for 10-20 h in an air atmosphere . Obtaining surface-coated LiNi 0.8 co 0.1 mn 0.1 o 2 , namely Li 2 MnTiO 4 coated LiNi 0.8 co 0.1 mn 0.1 o 2 .

Embodiment 3

[0041] Measure 1 mol of LiNi 0.8 co 0.1 mn 0.1 o 2 As the material to be coated, due to the existence of residual LiOH on the surface, the material is strongly alkaline, with a pH of about 12 and LiNi 0.8 co 0.1 mn 0.1 o 2 The residual lithium on the surface acts as Li 2 CoO 4 Lithium source, measure 0.05 mol of titanium dioxide as the titanium source, measure 0.05 mol of cobalt hydroxide as the cobalt source, mix the above materials uniformly by ball milling, and perform calcination at 400-800°C under air atmosphere for 10-20 h. Obtaining surface-coated LiNi 0.8 co 0.1 mn 0.1 o 2 , namely Li 2 CoO 4 coated LiNi 0.8 co 0.1 mn 0.1 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com