Negative plate and lithium ion battery

A technology of negative electrode sheet and negative electrode active material, which is applied in secondary batteries, battery pack parts, non-aqueous electrolyte battery electrodes, etc., can solve the problems of poor cycle performance and increased current density of lithium ion batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

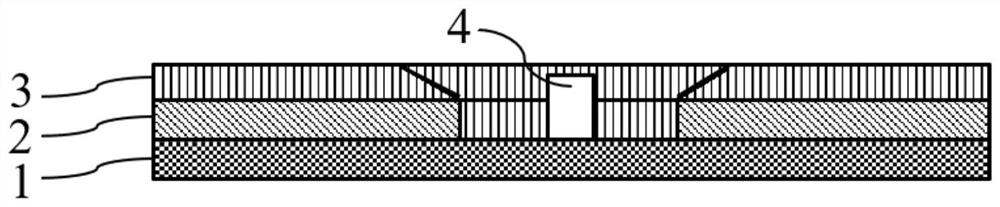

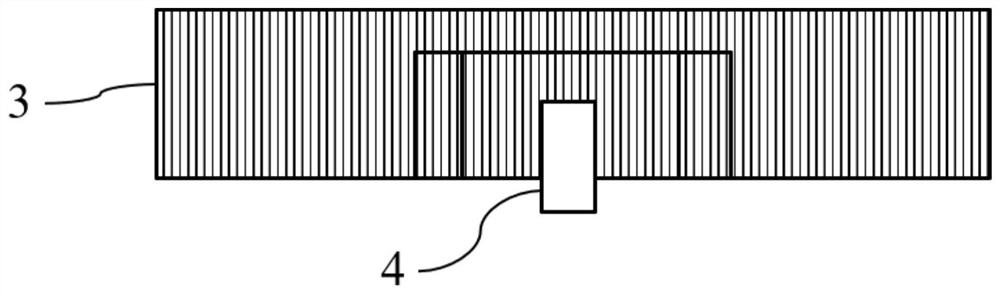

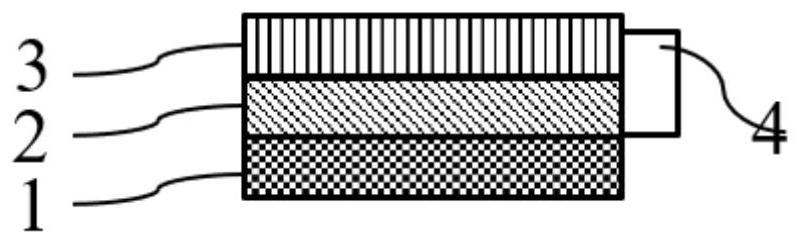

[0055] The front view of the negative plate provided by this embodiment is as Figure 2a As shown, the top view is as image 3 As shown, the left view is as Figure 1c shown, where:

[0056] The current collector is copper foil with a width of 81mm;

[0057] The first groove has a width of 81mm and a length of 30mm;

[0058] The second groove has a width of 25mm and a length of 10mm.

[0059] The average particle size of the negative electrode active material in the first active layer is 18 μm, and the degree of graphitization is 96%;

[0060] The average particle diameter of the negative electrode active material in the second active layer is 15 μm, and the degree of graphitization is 92%.

[0061] The preparation method of the negative plate provided in this embodiment comprises the following steps:

[0062] 1. Dissolve the graphite of 97 parts by mass, the carbon black of 0.7 parts by mass, the styrene-butadiene rubber of 1.3 parts by mass and the sodium carboxymethyl...

Embodiment 2

[0065] The front view of the negative plate provided by this embodiment is as Figure 2a As shown, the top view is as image 3 As shown, the left view is as Figure 1c shown, where:

[0066] The current collector is copper foil with a width of 81mm;

[0067] The first groove has a width of 81mm and a length of 40mm;

[0068] The second groove has a width of 25mm and a length of 10mm;

[0069] The average particle size of the negative electrode active material in the first active layer is 18 μm, and the degree of graphitization is 96%;

[0070] The average particle diameter of the negative electrode active material in the second active layer is 15 μm, and the degree of graphitization is 92%.

[0071] For the preparation method of the negative electrode sheet provided in this example, reference may be made to Example 1.

Embodiment 3

[0073] The front view of the negative plate provided by this embodiment is as Figure 2a As shown, the top view is as image 3 As shown, the left view is as Figure 1c shown, where:

[0074] The current collector is copper foil with a width of 81mm;

[0075] The first groove has a width of 81mm and a length of 50mm;

[0076] The second groove has a width of 25mm and a length of 10mm.

[0077] The average particle size of the negative electrode active material in the first active layer is 18 μm, and the degree of graphitization is 96%;

[0078] The average particle diameter of the negative electrode active material in the second active layer is 15 μm, and the degree of graphitization is 92%.

[0079] For the preparation method of the negative electrode sheet provided in this example, reference may be made to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com